Axial Compression Behavior of Wall-like Reinforced Concrete Columns Retrofitted Using Different FRP Schemes

Abstract

:1. Introduction

- A combination of layers of glass FRP (GFRP) and/or carbon FRP (CFRP) was extensively used for strengthening.

- The circumferential FRP combined with the longitudinal wraps of FRP help in enhancing the column strength.

- The low effectiveness of FRP wraps could be increased by transforming the rectangular cross-sectional shape to an elliptical cross-section.

- The addition of bolted steel plates along the column height in combination with the circumferential FRP wraps results in better confinement.

- Anchored and unanchored circumferential FRP wraps with strengthened corners were used to increase the confinement.

- The transformation of the shorter dimensions of the columns by use of semi-cylindrical attachments was effective in enhancing the column strength.

- The buckling of main rebars could be delayed for columns strengthened with c-shaped FRP wraps around the corners.

2. Experimental Program

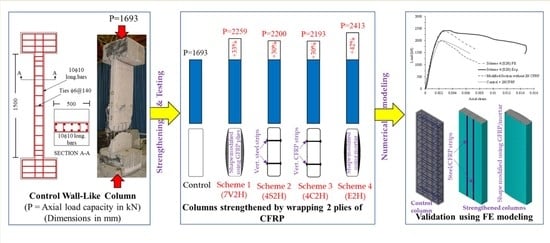

2.1. Specimen Details

- Avoiding casting in two or more layers when done in the vertical position, which could have resulted in construction joints.

- Having good quality control in placing and compaction of concrete, which was difficult to achieve in casting in the vertical position, especially due to the large size of the specimen and small width of the column.

- The ease of casting.

2.2. Material Characteristics

2.3. Strengthening Schemes

- Scheme 1 (7V2H): The column specimen was strengthened using seven plies of GFRP with fibers oriented vertically, and then two plies of CFRP (horizontally oriented fibers) were wrapped. The vertical plies were used for converting the rectangular column section to the elliptical shape for improving the confinement provided by CFRP sheets.

- Scheme 2 (4S2H): The column was drilled with twelve holes of 15 mm in diameter. Two CFRP sheets were wrapped horizontally. Four 30 mm wide steel strips of 5 mm thickness, two on each face and 138 mm apart, were then anchored using twelve bolts of 15 mm diameter.

- Scheme 3 (4C2H): Same as Scheme 2, except for the use of seven layers of CFRP strips with fibers oriented vertically in place of steel strips. The strips were anchored with the column using twelve bolts of 15 mm diameter.

- Scheme 4 (E2H): The column section was modified to the elliptical shape by applying mortar on the wider dimension of the column section. The strength of the mortar was approximately the same as that of the column concrete. The mortar thickness at the mid-width of the column was 20 mm, which was reduced gradually to zero at the vertical edges. The transformed column was wrapped after the hardening of mortar with two horizontal layers of CFRP sheet. The test results of this scheme have been reported in the authors’ earlier publication [19]. However, this scheme is being reported briefly for the sake of completeness.

2.4. Instrumentation

3. Discussion of Experimental Results

3.1. Modes of Failure of Columns

3.2. Axial Compression Behavior of Columns

3.3. Axial Strain of Columns

3.4. Dialation (Lateral Strains)

4. Numerical Modeling

4.1. Details of Mesh Discretization

- (a)

- Parent Concrete (Rectangular column section):Total number of nodes: 14,196Total number of elements: 11,550Element type: Eight node hexahedral elements of type C3D8R

- (b)

- Mortar for the transformation of the column to the elliptical shape:Total number of nodes: 4087Total number of elements: 2604Element type: Eight node hexahedral elements of type C3D8R

- (c)

- Steel ReinforcementTotal number of nodes: 1564Total number of elements: 1722Element type: Two node line elements of type T3D2

- (d)

- FRP LaminatesTotal number of nodes: 5148Total number of elements: 5082Element type: Four node quadrilateral elements of type S4R

4.2. Details of Concrete Model and Validation

4.3. Discussion of Numerical Results

5. Conclusions

- The study validated that RC wall-like columns can be strengthened using FRP confinement. Based on the experimental results, wrapping wall-like columns subjected to compression loading FRP sheets delays the occurrence of yielding in longitudinal rebars.

- For strengthened or un-strengthened columns, failure was attributed to concrete cover delamination and concrete crushing, followed by the buckling of the main steel bars.

- The maximum carrying capacity of the wall-like columns can be increased by more than 30% by adding vertical and horizontal FRP sheets around the column surface.

- The type of failure of the FRP-strengthened columns can be improved by: (i) anchoring the FRP sheets along the wide side of the column with a steel plate; or by (ii) modifying the shape of the column from rectangular to elliptical using mortar underneath the FRP sheets.

- The validation of the experimental and FE results reveals the significance of the numerical modeling that can be employed for predicting the deformation characteristics of both un-strengthened and retrofitted concrete wall-like columns. A low magnitude of prediction errors of less than 10% shows a reasonably close prediction. This demonstrates that the numerical modeling approach may be utilized in future studies to investigate additional strengthening schemes for RC wall-like columns. However, the convergence of the numerical model with experimental results needs to be further improved, especially for future numerical studies involving shear-strengthening.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Salloum, Y.A.; Almusallam, T.H.; Elsanadedy, H.M.; Iqbal, R.A. Effect of elevated temperature environments on the residual axial capacity of RC columns strengthened with different techniques. Constr. Build. Mater. 2016, 115, 345–361. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Al-Amri, G.S.; Siddiqui, N.A.; Almusallam, T.H.; Abbas, H. Effectiveness of CFRP strengthening in improving cyclic compression response of slender RC columns. J. Compos. Constr. 2018, 22, 04018009. [Google Scholar] [CrossRef]

- Siddiqui, N.; Abbas, H.; Almusallam, T.; Binyahya, A.; Al-Salloum, Y. Compression behavior of FRP-strengthened RC square columns of varying slenderness ratios under eccentric loading. J. Build. Eng. 2020, 32, 101512. [Google Scholar] [CrossRef]

- Siddiqui, N.A.; Alsayed, S.H.; Al-Salloum, Y.A.; Iqbal, R.A.; Abbas, H. Experimental investigation of slender circular RC columns strengthened with FRP composites. Constr. Build. Mater. 2014, 69, 323–334. [Google Scholar] [CrossRef]

- Harajli, M.H.; Hantouche, E.; Soudki, K. Stress-strain model for fiber-reinforced polymer jacketed concrete columns. Struct. J. 2006, 103, 672–682. [Google Scholar]

- Mirmiran, A.; Shahawy, M.; Samaan, M.; Echary, H.E.; Mastrapa, J.C.; Pico, O. Effect of column parameters on FRP-confined concrete. J. Compos. Constr. 1998, 2, 175–185. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A. Influence of edge sharpness on the strength of square concrete columns confined with FRP composite laminates. Compos. Part B Eng. 2007, 38, 640–650. [Google Scholar] [CrossRef]

- Wang, L.M.; Wu, Y.F. Effect of corner radius on the performance of CFRP-confined square concrete columns: Test. Eng. Struct. 2008, 30, 493–505. [Google Scholar] [CrossRef]

- Prota, A.; Manfredi, G.; Cosenza, E. Ultimate behavior of axially loaded RC wall-like columns confined with GFRP. Compos. Part B Eng. 2006, 37, 670–678. [Google Scholar] [CrossRef]

- Wang, Y.C.; Restrepo, J.I. Investigation of concentrically loaded reinforced concrete columns confined with glass fiber-reinforced polymer jackets. Struct. J. 2001, 98, 377–385. [Google Scholar]

- Tan, K.H. Strength enhancement of rectangular reinforced concrete columns using fiber-reinforced polymer. J. Compos. Constr. 2002, 6, 175–183. [Google Scholar] [CrossRef]

- Tanwongsval, S.; Maalej, M.; Paramasivam, P. Strengthening of RC wall-like columns with FRP under sustained loading. Mater. Struct. 2003, 36, 282–290. [Google Scholar] [CrossRef]

- Maalej, M.; Tanwongsval, S.; Paramasivam, P. Modelling of rectangular RC columns strengthened with FRP. Cem. Concr. Compos. 2003, 25, 263–276. [Google Scholar] [CrossRef]

- Pan, J.L.; Xu, T.; Hu, Z.J. Experimental investigation of load carrying capacity of the slender reinforced concrete columns wrapped with FRP. Constr. Build. Mater. 2007, 21, 1991–1996. [Google Scholar] [CrossRef]

- Kumutha, R.; Vaidyanathan, R.; Palanichamy, M.S. Behaviour of reinforced concrete rectangular columns strengthened using GFRP. Cem. Concr. Compos. 2007, 29, 609–615. [Google Scholar] [CrossRef]

- De Luca, A.; Matta, F.; Nanni, A. Behavior of full-scale glass fiber-reinforced polymer reinforced concrete columns under axial load. ACI Struct. J. 2010, 107, 589. [Google Scholar]

- Toutanji, H.; Han, M.; Gilbert, J.; Matthys, S. Behavior of large-scale rectangular columns confined with FRP composites. J. Compos. Constr. 2010, 14, 62–71. [Google Scholar] [CrossRef]

- De Luca, A.; Nardone, F.; Matta, F.; Nanni, A.; Lignola, G.P.; Prota, A. Structural evaluation of full-scale FRP-confined reinforced concrete columns. J. Compos. Constr. 2011, 1, 112–123. [Google Scholar] [CrossRef]

- Alsayed, S.H.; Almusallam, T.H.; Ibrahim, S.M.; Al-Hazmi, N.M.; Al-Salloum, Y.A.; Abbas, H. Experimental and numerical investigation for compression response of CFRP strengthened shape modified wall-like RC column. Constr. Build. Mater. 2014, 63, 72–80. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Choutopoulou, E.; Fotaki, E.; Skorda, M.; Stathopoulou, M.; Karlos, K. FRP confinement of wall-like reinforced concrete columns. Mater. Struct. 2016, 49, 651–664. [Google Scholar] [CrossRef]

- De Luca, A.; Nardone, F.; Lignola, G.P.; Prota, A.; Nanni, A. Wall-like reinforced concrete columns externally confined by means of glass FRP laminates. Adv. Struct. Eng. 2013, 16, 593–603. [Google Scholar] [CrossRef] [Green Version]

- Rasouli, M.; Broujerdian, V. 3D finite element modeling of FRP-confined rectangular short columns considering variation of Poisson’s ratio. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 44, 449–461. [Google Scholar] [CrossRef]

- Avossa, A.M.; Picozzi, V.; Ricciardelli, F. Load-Carrying Capacity of Compressed Wall-Like RC Columns Strengthened with FRP. Buildings 2021, 11, 285. [Google Scholar] [CrossRef]

- Kohnke, P. ANSYS Theory Reference Manual; Ansys Inc.: Canonsburg, PA, USA, 2013. [Google Scholar]

- Hassan, M.; Chaallal, O. Fiber-reinforced polymer confined rectangular columns: Assessment of models and design guidelines. ACI Struct. J. 2007, 104, 693. [Google Scholar]

- Rocca, S.; Galati, N.; Nanni, A. Review of design guidelines for FRP confinement of reinforced concrete columns of noncircular cross sections. J. Compos. Constr. 2008, 12, 80–92. [Google Scholar] [CrossRef] [Green Version]

- Foster, S.J.; Attard, M.M. Experimental tests on eccentrically loaded high strength concrete columns. Struct. J. 1997, 94, 295–303. [Google Scholar]

- ASTM E8/E8M-16a; Standard Test Methods for Tension Testing of Metallic Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- ASTM C39/C39M-17; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM D3039/D3039M-14; Method for Tensile Properties of Polymer Matrix Composite Materials. American Society for Testing and Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- Abaqus 6.17 Analysis User’s Guide, Section 12.9.3—Defining Damages; Dassault Systemes Simulia Corp.: Providence, RI, USA, 2017.

- Almusallam, T.H.; Alsayed, S.H. Stress–strain relationship of normal, high-strength and lightweight concrete. Mag. Concr. Res. 1995, 47, 39–44. [Google Scholar] [CrossRef]

| Material | CFRP | GFRP |

|---|---|---|

| Ultimate tensile strength in fiber direction (MPa) | 846 | 456 |

| Fracture strain | 0.011 | 0.018 |

| Elastic modulus in fiber direction (GPa) | 77.3 | 27.6 |

| Shear capacity (MPa) | 4.2 | 4.4 |

| Flexural capacity (MPa) | 670 | 282.4 |

| Flexural elastic modulus (GPa) | 47.5 | 14.6 |

| Sheet thickness (mm) | 1.0 | 1.3 |

| Scheme/Specimen | Yield Load (kN) | At Peak | At Failure | ||

|---|---|---|---|---|---|

| Load (kN) | Microstrain | Load (kN) | Microstrain | ||

| Control | 1668 | 1693 | 3000 | 1621 | 5100 |

| Scheme 1 (7V2H) | 2240 (34%) | 2259 (33%) | 1939 (−35%) | - | - |

| Scheme 2 (4S2H) | 2076 (24%) | 2200 (30%) | 4505 (+50%) | - | - |

| Scheme 3 (4C2H) | 1839 (10%) | 2193 (30%) | 2850 (−5%) | - | - |

| Scheme 4 (E2H) | 2413 (45%) | 2413 (42%) | 2620 (−12%) | 2020 (25%) | 11,000 (116%) |

| Location | Control | Scheme 1 (7V2H) | Scheme 2 (4S2H) | Scheme 3 (4C2H) | Scheme 4 (E2H) |

|---|---|---|---|---|---|

| At peak load | |||||

| Tie at top end of column | 530 | 2600 | 1000 | 1030 | 680 |

| Tie at mid-height of column | 470 | 400 | 600 | 490 | 530 |

| Lateral strain at surface of concrete/FRP | 380 | 330 | 500 | 330 | 740 |

| At failure load | |||||

| Tie at top end of column | 850 (60%) | 2930 (14%) | 2200 (120%) | 1560 (51%) | 870 (28%) |

| Tie at mid-height of column | 800 (70%) | 750 (88%) | 2600 (333%) | 3030 (518%) | 5000 (840%) |

| Lateral strain at surface of concrete/FRP | 380 | 330 | 500 | 330 | 740 |

| Concrete | ||

|---|---|---|

| Material model | Concrete damage plasticity (CDP) | |

| Unit weight (kg/m3) | 2320 | |

| Compressive strength—uniaxial (MPa) | 22.7 | |

| Ratio of initial biaxial compressive yield stress to initial uniaxial compressive yield stress, fb0/fc0 | 1.16 | |

| Dilation angle, ψ | 40 | |

| Eccentricity of the plastic potential surface, ε | 0.1 | |

| Ratio of the second stress invariant on the tensile meridian to compressive meridian at initial yield, Kc | 0.667 | |

| Viscosity parameter, μ | 0.001 | |

| Steel rebars | ||

| Material model | Elastic-Plastic | |

| Unit weight (kg/m3) | 7800 | |

| Elastic modulus (GPa) | 200 | |

| Poisson’s ratio | 0.3 | |

| Yield stress (MPa) | 486 | |

| FRP material | GFRP | CFRP |

| Material model | Anisotropic Elastic (with fail strain) | Anisotropic Elastic (with fail strain) |

| Unit weight (kg/m3) | 2000 | 2000 |

| Plie thickness (mm) | 1.5 | 1.5 |

| Elastic modulus in fiber direction (MPa) | 27,280 | 77,280 |

| Elastic modulus in transverse direction (MPa) | 400 | 400 |

| Fail Tensile strain (fiber direction) | 0.11 | 0.11 |

| Fail Compressive strain (fiber direction) | 0.01 | 0.01 |

| Fail Tensile strain (transverse direction) | 0.01 | 0.01 |

| Fail Compressive strain (transverse direction) | 0.01 | 0.01 |

| Fail Shear strain | 0.01 | 0.01 |

| Scheme | Load Deflection Curve Location | Load Value (kN) | Load Percent (%) | Stress and Strain in Rebars | |||

|---|---|---|---|---|---|---|---|

| Longitudinal Rebar | Ties | ||||||

| Stress (MPa) | Microstrain | Stress (MPa) | Microstrain | ||||

| Control | Pre peak | 475 | 27 | 61 | 306 | 9 | 47 |

| 1173 | 67 | 202 | 1011 | 65 | 324 | ||

| Peak | 1747 | 100 | 466 | 2330 | 179 | 893 | |

| Post peak | 1615 | 95 | 491 | 3099 | 261 | 1307 | |

| 1398 | 85 | 496 | 3928 | 281 | 1405 | ||

| 1069 | 61 | 538 | 5572 | 288 | 1442 | ||

| 828 | 47 | 572 | 6745 | 268 | 1339 | ||

| Scheme 1 (7V2H) | Pre peak | 494 | 22 | 61 | 306 | 10 | 49 |

| 1409 | 64 | 226 | 1132 | 75 | 377 | ||

| 2070 | 94 | 301 | 1506 | 162 | 808 | ||

| Peak | 2192 | 100 | 416 | 2109 | 202 | 1011 | |

| Post peak | 2199 | 100 | 413 | 2352 | 212 | 1062 | |

| 1767 | 80 | 408 | 2343 | 212 | 1062 | ||

| 1489 | 68 | 393 | 2292 | 224 | 1120 | ||

| Scheme 2 (4S2H) | Pre peak | 485 | 22 | 61 | 307 | 10 | 48 |

| 1376 | 64 | 228 | 1138 | 76 | 379 | ||

| 1883 | 87 | 352 | 1759 | 134 | 670 | ||

| Peak | 2158 | 100 | 481 | 2471 | 222 | 1108 | |

| Post peak | 1995 | 92 | 470 | 3128 | 246 | 1230 | |

| 1626 | 75 | 466 | 3501 | 288 | 1442 | ||

| 1528 | 71 | 467 | 3531 | 307 | 1534 | ||

| Scheme 3 (4C2H) | Pre peak | 639 | 31 | 94 | 470 | 25 | 125 |

| 1798 | 87 | 338 | 1688 | 135 | 674 | ||

| 2075 | 100 | 486 | 2455 | 231 | 1154 | ||

| Peak | 1912 | 92 | 462 | 2366 | 240 | 1199 | |

| Post peak | 1732 | 83 | 444 | 2279 | 245 | 1226 | |

| 1381 | 67 | 415 | 2130 | 279 | 1396 | ||

| 1062 | 51 | 415 | 2131 | 386 | 2649 | ||

| Scheme 4 (E2H) | Pre peak | 551 | 23 | 61 | 307 | 11 | 62 |

| 2367 | 100 | 313 | 1565 | 155 | 1065 | ||

| Peak | 2371 | 100 | 473 | 2363 | 237 | 1701 | |

| Post peak | 2367 | 100 | 488 | 2791 | 258 | 1951 | |

| 2357 | 99 | 493 | 3414 | 288 | 2437 | ||

| 2211 | 93 | 520 | 5098 | 317 | 2962 | ||

| 0 | 0 | 579 | 6961 | 348 | 3978 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, H.; Ibrahim, S.M.; Al-Hazmi, N.; Elsanadedy, H.; Almusallam, T.; Al-Salloum, Y. Axial Compression Behavior of Wall-like Reinforced Concrete Columns Retrofitted Using Different FRP Schemes. Buildings 2023, 13, 26. https://doi.org/10.3390/buildings13010026

Abbas H, Ibrahim SM, Al-Hazmi N, Elsanadedy H, Almusallam T, Al-Salloum Y. Axial Compression Behavior of Wall-like Reinforced Concrete Columns Retrofitted Using Different FRP Schemes. Buildings. 2023; 13(1):26. https://doi.org/10.3390/buildings13010026

Chicago/Turabian StyleAbbas, Husain, S. M. Ibrahim, Naif Al-Hazmi, Hussein Elsanadedy, Tarek Almusallam, and Yousef Al-Salloum. 2023. "Axial Compression Behavior of Wall-like Reinforced Concrete Columns Retrofitted Using Different FRP Schemes" Buildings 13, no. 1: 26. https://doi.org/10.3390/buildings13010026