Life Cycle Assessment of Embodied Carbon in Buildings: Background, Approaches and Advancements

Abstract

:1. Introduction

2. Estimation of the Embodied Carbon of Buildings

3. Research Methodology

3.1. Process Analysis in LCA

3.2. Input–Output (IO) Analysis

3.3. Hybrid Analysis

4. Uncertainty in LCA

- Incomplete and insufficient data (for example, lack of information on construction materials, and building geometry);

- Inaccuracies in modeling models (for example, energy analysis software, building utilization projections);

- The undefined character of the future (for example, changes in usage, service life, technology advancements, socioeconomic shifts, and so on).

- When it comes to the problem of measuring or estimating embodied carbon, there are four types of uncertainty to consider [28]:

- Uncertainty concerning the embodied carbon emissions in different stages of building components, materials, and the entire structure;

- Uncertainty regarding the amount of carbon that will be embodied in the future and the service life of construction materials and components, with technological advancement;

- Uncertainty about future occurrences that will take place during the service life of built assets, such as component replacement, component life span, use modifications, and end of life;

- Uncertainty over the capabilities and methods of measurement.

4.1. Probabilistic Approaches

4.1.1. Current Measurement

- A single figure that indicates the best estimate is referred to as a single-point estimate or “best guesstimate”;

- A range of possible values is listed in ascending order with no indication of where the actual value falls. This is defined when the lowest and highest potential values are uniformly divided;

- An estimate of three points, also known as 3PE, is based on the lowest, most likely, and possible credible values. This can be defined by a triangular probability distribution. The 3PE approach is an excellent approach to capturing the expertise of seasoned practitioners who can advise on the lowest conceivable estimate, and for an unknown variable with the highest possible values;

- An empirical distribution of data from similar situations where the carbon embodied was assessed. The instances can be utilized as a probability distribution if they reflect a representative sample of the range of potential values.

4.1.2. Life Cycle Measurement

4.1.3. Tree Representations

4.1.4. Monte Carlo Simulation (MCS)

4.2. Decision-Making under Uncertainty

4.3. Flexible Strategies

5. Introducing Early Environmental Assessment in the Design Process

- Generally, construction professionals utilize a simplified geometric model, which predicts the areas and quantities of building components based on restricted geometric input data. A model, which can calculate both the areas and consumption of building elements, might be used early in the design phase to estimate the influence of building form on embodied carbon. Through this method, a link between the geometric model’s accuracy and its use time can be established;

- Rather than limiting the embodied carbon assessment of building elements to after the completion of a chosen building design, a more effective method would be to select suitable building elements from an inventory of a large number of predefined building elements with embodied carbon results at the early design stage. This method would have a greater impact.

- Building Geometry Calculation: Based on minimal geometric input data, a simpler geometric building model is built, which calculates the area and quantity of construction elements.

- Building and Material Lifespan: As the building comprises different elements, and each element has a different lifespan within the life span of the whole building, it is necessary to set out a process that identifies both.

- Parametric Variation: The building elements that are predefined cover the diversity of design solutions for all internal and external elements, primarily related to the typological variations’ specification; therefore, the first step is the selection of predefined building elements according to the requirements.

- Embodied Carbon Calculation: Every typological variation is subjected to the evaluation of embodied carbon throughout its life cycle. The data must be compiled into an inventory of pre-defined building elements and carbon data.

- Tool for Embodied Carbon Design: The design tool pairs geometric data with specified construction parts to quickly assess the embodied carbon of structures.

- Detailed Building LCA vs. Simplified: The results obtained from the simple tool are compared to those of a thorough building LCA, and the differences are addressed.

6. Embodied Carbon in Different Stages of the Building Life Cycle

7. Sustainable Technologies and Embodied Carbon

Building Materials Design Strategies for Low Embodied Carbon

8. Mitigation of the Embodied Carbon

8.1. Macro Perspective

8.1.1. National Level

8.1.2. Regional Level

8.2. Micro Perspective

- The I-O-based hybrid model was created to give process-based data for the I-O analysis’s most energy-consuming pathways.

- I-O analysis is used to determine the product under study’s initial overall environmental load.

- Using I-O analysis to break down a complicated upstream process and identify the main pathways that have a big environmental effect.

- Key route modification using process-based inventory data on both supplied amount and energy intensity.

- Taking the original overall environmental effect determined by the I-O model and subtracting the corresponding I-O value of the main routes reflected in the process inventory.

- Including updated energy routes from process-based analysis in the remaining unmodified I-O framework.

9. Analysis and Discussion

10. Conclusions

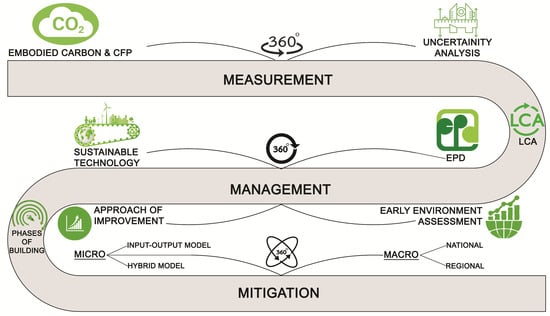

- Embodied emissions in all aspect of construction are covered, with the main focus of study being on the measurement, management and mitigation strategies of embodied carbon;

- As estimate is an important part of any debate, so our measurement covers the uncertainty analysis from diverse points of view through a novel approach. Management covers the early design tools and the significance of the life cycle stages, and mitigation covers the strategies in place to reduce the embodied carbon, although reductions in embodied carbon are a subjective topic and depend on region. Analysis covers the ideal approaches for mitigation, irrespective of the region;

- In this study, for the measurement of the embodied carbon, different probabilistic approaches have been studied, such as current measurement, life cycle measurement, tree representation, and Monte Carlo simulations;

- It is identified that life cycle measurement is appropriate for existing buildings, but in most of the studies, uncertainty is excluded, and the demolition and service life requirements of the buildings are considered constant. MCS, on the other hand, can estimate the embodied carbon based on future probability, and is more accurate than the other two, but is not used frequently because of the complexity of the process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Soust-Verdaguer, B.; Galeana, I.B.; Llatas, C.; Montes, M.; Hoxha, E.; Passer, A. How to conduct consistent environmental, economic, and social assessment during the building design process. A BIM-based Life Cycle Sustainability Assessment method. J. Build. Eng. 2021, 45, 103516. [Google Scholar] [CrossRef]

- Azis, A.A.A.; Memon, A.H.; Rahman, I.A.; Nagapan, S.; Latif, Q.B.A.I. Challenges faced by construction industry in accomplishing sustainablity goals. In Proceedings of the 2012 IEEE Symposium on Business, Engineering and Industrial Applications, Bandung, Indonesia, 23–26 September 2012; pp. 630–634. [Google Scholar] [CrossRef]

- Buildings and Climate Change Summary for Decision-Makers Sustainable Buildings & Climate Initiative. Available online: http://www.tge.ca (accessed on 21 July 2022).

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Pomponi, F.; Giesekam, J.; Hart, J.; Bernardino, D.A. Embodied Carbon: Status Quo and Suggested Roadmap. 2020. Available online: https://zerowastescotland.org.uk/sites/default/files/Embodied_carbon_spreads%20final.pdf (accessed on 31 October 2022).

- International Organization for Standardization. Environmental Management: Life Cycle Assessment; Requirements and Guidelines; ISO: Geneva, Switzerland, 2006; Volume 14044. [Google Scholar]

- Rashid, A.F.A.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef] [Green Version]

- Dossche, C.; Boel, V.; De Corte, W. Use of Life Cycle Assessments in the Construction Sector: Critical Review. Procedia Eng. 2017, 171, 302–311. [Google Scholar] [CrossRef]

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V. Varun Life cycle assessment of buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Vigon, B.W.; Harrison, C.L. Life-Cycle Assessment: Inventory Guidelines and Principles; U.S. Environmental Protection Agency: Washington, DC, USA, 1993.

- Eaton, K.; Amato, A. A comparative life cycle assessment of steel and concrete framed office buildings. J. Constr. Steel Res. 1998, 46, 286–287. [Google Scholar] [CrossRef]

- Hanssen, O.J. Status of Life Cycle Assessment (LCA) activities in the Nordic Region. Int. J. Life Cycle Assess. 1999, 4, 315–320. [Google Scholar] [CrossRef]

- Kim, S.Y. Life Cycle Assessment on Environment. 1998. Available online: http://inis.iaea.org/Search/search.aspx?orig_q=RN:46110662 (accessed on 23 August 2022).

- Clark, G.; de Leeuw, B. How to improve adoption of LCA. Int. J. Life Cycle Assess. 1999, 4, 184–187. [Google Scholar] [CrossRef]

- Pennington, D.; Potting, J.; Finnveden, G.; Lindeijer, E.; Jolliet, O.; Rydberg, T.; Rebitzer, G. Life cycle assessment Part 2: Current impact assessment practice. Environ. Int. 2004, 30, 721–739. [Google Scholar] [CrossRef]

- Kofoworola, O.F.; Gheewala, S.H. Environmental life cycle assessment of a commercial office building in Thailand. Int. J. Life Cycle Assess. 2008, 13, 498–511. [Google Scholar] [CrossRef]

- Khasreen, M.M.; Banfill, P.F.G.; Menzies, G.F. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Dixit, M.; Culp, C.H.; Fernández-Solís, J.L. System boundary for embodied energy in buildings: A conceptual model for definition. Renew. Sustain. Energy Rev. 2013, 21, 153–164. [Google Scholar] [CrossRef]

- Grant, A.; Ries, R. Impact of building service life models on life cycle assessment. Build. Res. Inf. 2012, 41, 168–186. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Scope-based carbon footprint analysis of U.S. residential and commercial buildings: An input–output hybrid life cycle assessment approach. Build. Environ. 2014, 72, 53–62. [Google Scholar] [CrossRef]

- Vandenbroucke, M.; Galle, W.; De Temmerman, N.; Debacker, W.; Paduart, A. Using Life Cycle Assessment to Inform Decision-Making for Sustainable Buildings. Buildings 2015, 5, 536–559. [Google Scholar] [CrossRef]

- Nwodo, M.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- Hernandez, P.; Oregi, X.; Longo, S.; Cellura, M. Life-Cycle Assessment of Buildings. In Handbook of Energy Efficiency in Buildings: A Life Cycle Approach; Elsevier: Amsterdam, The Netherlands, 2019; pp. 207–261. [Google Scholar] [CrossRef]

- Mastrucci, A.; Marvuglia, A.; Leopold, U.; Benetto, E. Life Cycle Assessment of building stocks from urban to transnational scales: A review. Renew. Sustain. Energy Rev. 2017, 74, 316–332. [Google Scholar] [CrossRef]

- Song, X.; Carlsson, C.; Kiilsgaard, R.; Bendz, D.; Kennedy, H. Life Cycle Assessment of Geotechnical Works in Building Construction: A Review and Recommendations. Sustainability 2020, 12, 8442. [Google Scholar] [CrossRef]

- Bahramian, M.; Yetilmezsoy, K. Life cycle assessment of the building industry: An overview of two decades of research (1995–2018). Energy Build. 2020, 219, 109917. [Google Scholar] [CrossRef]

- Su, S.; Zhang, H.; Zuo, J.; Li, X.; Yuan, J. Assessment models and dynamic variables for dynamic life cycle assessment of buildings: A review. Environ. Sci. Pollut. Res. 2021, 28, 26199–26214. [Google Scholar] [CrossRef]

- Suh, S.; Huppes, G. Methods for Life Cycle Inventory of a product. J. Clean. Prod. 2005, 13, 687–697. [Google Scholar] [CrossRef]

- Heijungs, R. A generic method for the identification of options for cleaner products. Ecol. Econ. 1994, 10, 69–81. [Google Scholar] [CrossRef] [Green Version]

- Rowley, H.V.; Lundie, S.; Peters, G.M. A hybrid life cycle assessment model for comparison with conventional methodologies in Australia. Int. J. Life Cycle Assess. 2009, 14, 508–516. [Google Scholar] [CrossRef]

- Lenzen, M. Errors in Conventional and Input-Output—Based Life—Cycle Inventories. J. Ind. Ecol. 2000, 4, 127–148. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Peng, Y.; Feng, Y.; Mao, C. Uncertainty analysis for measuring greenhouse gas emissions in the building construction phase: A case study in China. J. Clean. Prod. 2016, 129, 183–195. [Google Scholar] [CrossRef] [Green Version]

- Leontief, W. Environmental Repercussions and the Economic Structure: An Input-Output Approach. Rev. Econ. Stat. 1970, 52, 262–271. [Google Scholar] [CrossRef]

- Suh, S.; Lenzen, M.; Treloar, G.J.; Hondo, H.; Horvath, A.; Huppes, G.; Jolliet, O.; Klann, U.; Krewitt, W.; Moriguchi, Y.; et al. System Boundary Selection in Life-Cycle Inventories. Environ. Sci. Technol. 2004, 38, 657–664. [Google Scholar] [CrossRef]

- Heijungs, R.; Suh, S. The Computational Structure of Life Cycle Assessment; Springer: Dordrecht, The Netherlands, 2002. [Google Scholar] [CrossRef]

- Briggs, W. The Soul of Modeling, Probability & Statistics; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- de Haes, H.A.U. Applications of life cycle assessment: Expectations, drawbacks and perspectives. J. Clean. Prod. 1993, 1, 131–137. [Google Scholar] [CrossRef]

- Heijungs, R. Identification of key issues for further investigation in improving the reliability of life-cycle assessments. J. Clean. Prod. 1996, 4, 159–166. [Google Scholar] [CrossRef] [Green Version]

- Funtowicz, S.O.; Ravetz, J.R. Uncertainty and Quality in Science for Policy Kluwer; Springer: Berlin/Heidelberg, Germany, 1990; Volume 15. [Google Scholar] [CrossRef]

- Wang, E.; Shen, Z. A hybrid Data Quality Indicator and statistical method for improving uncertainty analysis in LCA of complex system—Application to the whole-building embodied energy analysis. J. Clean. Prod. 2013, 43, 166–173. [Google Scholar] [CrossRef]

- Weidema, B.; Wesnæs, M. Data quality management for life cycle inventories—An example of using data quality indicators. J. Clean. Prod. 1996, 4, 167–174. [Google Scholar] [CrossRef]

- Coulon, R.; Camobreco, V.; Teulon, H.; Besnainou, J. Data quality and uncertainty in LCI. Int. J. Life Cycle Assess. 1997, 2, 178–182. [Google Scholar] [CrossRef]

- Björklund, A.E. Survey of approaches to improve reliability in lca. Int. J. Life Cycle Assess. 2002, 7, 64–72. [Google Scholar] [CrossRef]

- Gantner, J.; Fawcett, W.; Ellingham, I. Probabilistic Approaches to the Measurement of Embodied Carbon in Buildings. In Embodied Carbon in Buildings: Measurement, Management, and Mitigation; Springer: Berlin/Heidelberg, Germany, 2018; pp. 23–50. [Google Scholar] [CrossRef]

- Cowles, M.K.; Carlin, B.P. Markov Chain Monte Carlo Convergence Diagnostics: A Comparative Review. J. Am. Stat. Assoc. 1996, 91, 883. [Google Scholar] [CrossRef]

- Crés, H. Gollier, C.: The Economics of Risk and Time. XX, 445 pp. MIT Press, Cambridge, Mass. 2001. Hardcover £ 34.50. J. Econ. 2003, 80, 178–179. [Google Scholar] [CrossRef]

- Marsh, R.; Rasmussen, F.N.; Birgisdottir, H. Embodied Carbon Tools for Architects and Clients Early in the Design Process. In Embodied Carbon in Buildings: Measurement, Management, and Mitigation; Springer: Berlin/Heidelberg, Germany, 2018; pp. 167–190. [Google Scholar] [CrossRef]

- Subramanian, V.; Ingwersen, W.; Hensler, C.; Collie, H. Comparing product category rules from different programs: Learned outcomes towards global alignment. Int. J. Life Cycle Assess. 2012, 17, 892–903. [Google Scholar] [CrossRef]

- Fet, A.M.; Skaar, C. Eco-labeling, Product Category Rules and Certification Procedures Based on ISO 14025 Requirements. Int. J. Life Cycle Assess. 2006, 11, 49–54. [Google Scholar] [CrossRef]

- ISO 14025; Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures. International Organization for Standardization: Geneva, Switzerland, 2006.

- EN 15804: 2012+ A1: 2013; Sustainability of Construction Works-Environmental Product Decla-Rations-Core Rules for the Product Category of Construction Products. Publications Office of the European Union Luxemburg: Luxemburg, 2013.

- TR 15941; Sustainability of Construction Works. Environmental Product Declarations. Methodology for Selection and Use of Generic Data. BSI (British Standards Institution): London, UK, 2010.

- EN 15643-1; Sustainability of Construction Works—Sustainability Assessment of Buildings—Part 1: General Framework. CEN: Brussels, Belgium, 2010.

- Passer, A.; Lasvaux, S.; Allacker, K.; De Lathauwer, D.; Spirinckx, C.; Wittstock, B.; Kellenberger, D.; Gschösser, F.; Wall, J.; Wallbaum, H. Environmental product declarations entering the building sector: Critical reflections based on 5 to 10 years experience in different European countries. Int. J. Life Cycle Assess. 2015, 20, 1199–1212. [Google Scholar] [CrossRef] [Green Version]

- Crowther, P. Re-valuing construction materials and components through design for disassembly. In Unmaking Waste in Pro-duction and Consumption: Towards the Circular Economy; Emerald Publishing Limited: Bingley, UK, 2018. [Google Scholar] [CrossRef]

- Randell, P.; Pickin, J.; Reviewers, B.G.; Wardle, C. Waste Generation and Resource Recovery in Australia Final Report Pre-Pared for Department of Sustainability, Environment, Water, Population and Communities Waste Generation and Resource Recovery in Australia Reporting Period 2010/11 Final Report Version 2.6 P321 Blue Environment Prints on 100% Recycled Content Paper. 2010. Available online: www.blueenvironment.com.au (accessed on 31 October 2022).

- Yuan, H.; Lu, W.; Hao, J.J. The evolution of construction waste sorting on-site. Renew. Sustain. Energy Rev. 2013, 20, 483–490. [Google Scholar] [CrossRef] [Green Version]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2012, 15, 81–91. [Google Scholar] [CrossRef]

- Mália, M.; de Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and demolition waste indicators. Waste Manag. Res. J. Sustain. Circ. Econ. 2013, 31, 241–255. [Google Scholar] [CrossRef]

- Arslan, H.; Cosgun, N.; Salg, B. Construction and Demolition Waste Management in Turkey. In Waste Management—An Integrated Vision; InTech: Vienna, Austria, 2012. [Google Scholar] [CrossRef] [Green Version]

- Marshall, R.E.; Farahbakhsh, K. Systems approaches to integrated solid waste management in developing countries. Waste Manag. 2013, 33, 988–1003. [Google Scholar] [CrossRef] [PubMed]

- Banias, G.; Achillas, C.; Vlachokostas, C.; Moussiopoulos, N.; Tarsenis, S. Assessing multiple criteria for the optimal location of a construction and demolition waste management facility. Build. Environ. 2010, 45, 2317–2326. [Google Scholar] [CrossRef]

- Royal Institution of Chartered Engineers. Whole Life Carbon Assessment for the Built Environment; Royal Institution of Chartered Surveyors: London, UK, 2017. [Google Scholar]

- Ding, G.K.C. Embodied Carbon in Construction, Maintenance and Demolition in Buildings. In Embodied Carbon in Buildings: Measurement, Management, and Mitigation; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 217–245. [Google Scholar] [CrossRef]

- Lenzen, M.; Pade, L.-L.; Munksgaard, J. CO2Multipliers in Multi-region Input-Output Models. Econ. Syst. Res. 2004, 16, 391–412. [Google Scholar] [CrossRef]

- Chen, Z.-M.; Chen, G. Virtual water accounting for the globalized world economy: National water footprint and international virtual water trade. Ecol. Indic. 2012, 28, 142–149. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-cycle energy analysis of prefabricated building components: An input–output-based hybrid model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef] [Green Version]

- Hong, J.; Shen, G.Q.; Feng, Y.; Lau, W.S.-T.; Mao, C. Greenhouse gas emissions during the construction phase of a building: A case study in China. J. Clean. Prod. 2015, 103, 249–259. [Google Scholar] [CrossRef] [Green Version]

- Acquaye, A.A.; Wiedmann, T.; Feng, K.; Crawford, R.H.; Barrett, J.; Kuylenstierna, J.; Duffy, A.P.; Koh, S.C.L.; McQueen-Mason, S. Identification of ‘Carbon Hot-Spots’ and Quantification of GHG Intensities in the Biodiesel Supply Chain Using Hybrid LCA and Structural Path Analysis. Environ. Sci. Technol. 2011, 45, 2471–2478. [Google Scholar] [CrossRef] [Green Version]

- Defourny, J.; Thorbecke, E. Structural Path Analysis and Multiplier Decomposition within a Social Accounting Matrix Framework. Econ. J. 1984, 94, 111. [Google Scholar] [CrossRef]

- Du, P.; Wood, A.; Stephens, B.; Song, X. Life-Cycle Energy Implications of Downtown High-Rise vs. Suburban Low-Rise Living: An Overview and Quantitative Case Study for Chicago. Buildings 2015, 5, 1003–1024. [Google Scholar] [CrossRef] [Green Version]

- Zhu, W.; Feng, W.; Li, X.; Zhang, Z. Analysis of the embodied carbon dioxide in the building sector: A case of China. J. Clean. Prod. 2020, 269, 122438. [Google Scholar] [CrossRef]

- Skullestad, J.L.; Bohne, R.A.; Lohne, J. High-rise Timber Buildings as a Climate Change Mitigation Measure—A Comparative LCA of Structural System Alternatives. Energy Procedia 2016, 96, 112–123. [Google Scholar] [CrossRef] [Green Version]

- Kishore, K.; Gupta, N. Mechanical characterization and assessment of composite geopolymer concrete. Mater. Today Proc. 2020, 44, 58–62. [Google Scholar] [CrossRef]

- Tomar, R.; Kishore, K.; Parihar, H.S.; Gupta, N. A comprehensive study of waste coconut shell aggregate as raw material in concrete. Mater. Today Proc. 2020, 44, 437–443. [Google Scholar] [CrossRef]

- Parashar, A.K.; Gupta, A. Investigation of the effect of bagasse ash, hooked steel fibers and glass fibers on the mechanical properties of concrete. Mater. Today Proc. 2020, 44, 801–807. [Google Scholar] [CrossRef]

- Gupta, A. Investigation of the strength of ground granulated blast furnace slag based geopolymer composite with silica fume. Mater. Today Proc. 2020, 44, 23–28. [Google Scholar] [CrossRef]

- Alotaibi, B.S.; Khan, S.A.; Abuhussain, M.A.; Al-Tamimi, N.; Elnaklah, R.; Kamal, M.A. Life Cycle Assessment of Embodied Carbon and Strategies for Decarbonization of a High-Rise Residential Building. Buildings 2022, 12, 1203. [Google Scholar] [CrossRef]

- Su, X.; Zhang, X. A detailed analysis of the embodied energy and carbon emissions of steel-construction residential buildings in China. Energy Build. 2016, 119, 323–330. [Google Scholar] [CrossRef]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Atmaca, A.; Atmaca, N. Life cycle energy (LCEA) and carbon dioxide emissions (LCCO2A) assessment of two residential buildings in Gaziantep, Turkey. Energy Build. 2015, 102, 417–431. [Google Scholar] [CrossRef]

- Wralsen, B.; O’Born, R.; Skaar, C. Life cycle assessment of an ambitious renovation of a Norwegian apartment building to nZEB standard. Energy Build. 2018, 177, 197–206. [Google Scholar] [CrossRef]

| Title | Goal | Methodology | Relevant Conclusion | Reference |

|---|---|---|---|---|

| Life-cycle assessment: Inventory guidelines and principles | Identification of a generalized method for inventory development through a template and to provide set of rules for necessary assumptions. | Developing a general framework and addressing general issues through literature study. | Establishment of the life cycle assessment process, and for the implementation of product life cycle assessment, development of guidelines and principles. | [10] |

| A comparative life cycle assessment of steel and concrete framed office buildings | Assessment of the environmental impact of a structurally framed office building based on material and operation. | Case study of two office buildings and comparison with possible renovations. | CO2 emissions from building materials can be used as a relevant environmental parameter for LCA. | [11] |

| Status of Life Cycle Assessment (LCA) activities in the Nordic Region | Comparison between the framework provided by ISO 14,040 and the process followed on the ground. | Case study of 350 studies from industrial companies and research institutes from the Nordic Region. | LCA has not been used in the strict sense presented in the standard and the system approach has also been modified according to need. | [12] |

| Life Cycle Assessment on Environment | Covers background and possible future advancement of the LCA. | Literature study. | The possible intervention of software systems and databases in the LCA process. | [13] |

| How to improve the adoption of LCA | Assessment of the progress in LCA | Literature review and survey. | For better LCA adoption, the focus should be on the research of simple methodologies and the need for LCA experts. | [14] |

| Life cycle assessment Part 2: Current impact assessment practice | Assessment of the development of LCA in different fields and possible collaborations to provide future indicators | Literature review. | LCA of each stage is interlinked with each other through various parameters that are neglected in the assessment. | [15] |

| Environmental life cycle assessment of a commercial office building in Thailand | Environmental LCA of A commercial office building | Case study: using input–output process. | Assessment of building from construction to demolition based on ISO 14,040 methodology. | [16] |

| Life-Cycle Assessment and the Environmental Impact of Buildings: A Review | LCA review considers current advancements from a building perspective. | Literature review and case study. | Need for LCA in the building sector and its importance as a decision-making support tool. | [17] |

| Life cycle assessment of buildings: A review | To identify the environmental impact of the entire service life | Literature review of existing assessments of service life of buildings | The life cycle of a building operation phase constitutes the most emissions. | [9] |

| Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review | Review the literature on LCA, life cycle energy analysis and life cycle cost analysis | Literature review | Generally, studies are carried out on low-constructed buildings and not on traditional buildings. | [18] |

| Life cycle assessment in the construction sector: A review | Overview of the current situation of LCA in the construction industry | Literature review | Phases like choice of material, construction, demolition etc., also play a major role in the minimization of LCA. | [19] |

| System boundary for embodied energy in buildings: A conceptual model for the definition | To develop a comprehensive system boundary model for life cycle energy analysis and quantifying embodied energy. | System proposal based on literature review. | Minimization of incomplete, inaccurate, and inconsistent data from numerous parameters through the proposed system. | [20] |

| Impact of building service life models on life cycle assessment | Development of a process for the whole LCA of the building. | Literature review and case study. | Examination of the effect of materials and systems in building operation, maintenance, repair, and replacement by modelling process. | [21] |

| Scope-based carbon footprint analysis of U.S. residential and commercial buildings: An input–output hybrid life cycle assessment approach | To assess the carbon footprint of the selected building based on different criteria or scopes. | Case study: based on hybrid analysis. | Transportation is identified as an important factor for the assessment, which links through every life cycle stage. | [22] |

| Using Life Cycle Assessment to Inform Decision-Making for Sustainable Buildings | Identification of the long-term environmental consequences of various design strategies | Case study: based on hybrid analysis. | Development of a framework that considers future refurbishment. | [23] |

| A review of life cycle assessment of buildings using a systematic approach | Recent advancements in the LCA of buildings | Bibliometric approach. | Provides pattern of growth of interest in building LCA. | [24] |

| Life-Cycle Assessment of Buildings | To evaluate the impacts of products from cradle to grave in building life cycle | Review paper. | The life cycle perspective of the whole building’s life cycle serves to evaluate the environmental benefits of reducing building energy. | [25] |

| Life Cycle Assessment of building stocks from urban to transnational scales: A review | To evaluate the environmental impact of building stock from urban to translational. | Review of existing case studies. | Limitations and opportunities of LCA of different building stocks are discussed and analysed for future work. | [26] |

| Life Cycle Assessment of Geotechnical Works in Building Construction: A Review and Recommendations | To address the geotechnical works in the LCA of buildings | Literature review. | Development of a unified framework to address the geotechnical works. | [27] |

| Life cycle assessment of the building industry: An overview of two decades of research (1995–2018) | Background and future scope in the LCA of buildings | Bibliometric approach. | Variation between different studies based on different parameters has been identified. | [28] |

| Assessment models and dynamic variables for dynamic life cycle assessment of buildings: a review | Comparison between the present methodological progress and synthesized dynamic assessment models | Literature review and proposed dynamic model. | Dynamic LCA offers important inferences for environmental practice. | [29] |

| Location | Structure | No. of Floors | Floor Area (m2) | Life Span (Years) | Life Cycle Inventory Technique | Emission (Kg CO2/m2) | Uncertainty | Reference |

|---|---|---|---|---|---|---|---|---|

| India | Reinforced concrete | 31 | 28,445 | 75 | Hybrid | 414 | Excluded | [80] |

| China | Steel | 6, 11,18 | 5524, 5544, 9574 | 30 | Process-based | 800–1000 | Excluded | [81] |

| USA, Norway | Timber | 7, 12, 21 | 6097, 10,542, 11,823 | 60 | Process-based | −234.8, 441.8 | Excluded | [75] |

| Australia | Prefabricated modular | 8 | 3943 | 50 | Hybrid | 864.04, 578.23, 629.46 | Excluded | [82] |

| Turkey | Reinforced Concrete | 13 | 7445 | 50 | Process-based | 105 | Excluded | [83] |

| Norway | Concrete | 9 | 3700 | 30 | Process-based | 228.41 | Excluded | [84] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, S.A.; Alam, T.; Khan, M.S.; Blecich, P.; Kamal, M.A.; Gupta, N.K.; Yadav, A.S. Life Cycle Assessment of Embodied Carbon in Buildings: Background, Approaches and Advancements. Buildings 2022, 12, 1944. https://doi.org/10.3390/buildings12111944

Khan SA, Alam T, Khan MS, Blecich P, Kamal MA, Gupta NK, Yadav AS. Life Cycle Assessment of Embodied Carbon in Buildings: Background, Approaches and Advancements. Buildings. 2022; 12(11):1944. https://doi.org/10.3390/buildings12111944

Chicago/Turabian StyleKhan, Sahil Ali, Tabish Alam, Mohammad Saaim Khan, Paolo Blecich, Mohammad Arif Kamal, Naveen Kumar Gupta, and Anil Singh Yadav. 2022. "Life Cycle Assessment of Embodied Carbon in Buildings: Background, Approaches and Advancements" Buildings 12, no. 11: 1944. https://doi.org/10.3390/buildings12111944