Stress Triaxiality and Lode Angle Parameter Characterization of Flat Metal Specimen with Inclined Notch

Abstract

:1. Introduction

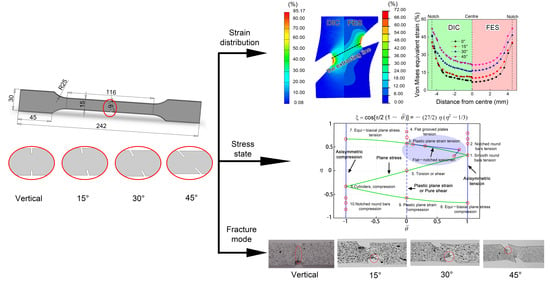

2. Experiment, Simulation and Characterization

2.1. DIC Experiment and Finite Element Simulation

2.2. Characterization of Stress Triaxiality and Lode Angle Parameter

3. Results and Discussion

3.1. Effect of Notch Angle on Load-Displacement Curve

3.2. Effect of Notch Angle on Strain Field

3.2.1. Comparison of Strain Fields by DIC and Finite Element Simulation

3.2.2. Strain Distribution and Evolution by DIC

3.3. Effect of Notch Angle on Stress Triaxiality and Lode Angle Parameter

3.3.1. Distribution and Evolution of Stress Triaxiality

3.3.2. Distribution and Evolution of Lode Angle Parameter

3.3.3. Characterization of Stress State

3.4. Effect of Stress State on Failure Mode

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, Y.; Jiang, W.C.; Zhang, W.Y.; Zhang, Y.C.; Woo, W.; Tu, S.T. Notch effect on creep damage for Hastelloy C276-BNi2 brazing joint. Mater. Des. 2015, 84, 212–222. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Chen, C.; Jiang, W.C.; Tu, S.T.; Zhang, X.C. Evaluation of the creep crack growth behavior in 9Cr–1Mo steel under different stress conditions. Int. J. Press. Vessel. Pip. 2020, 88, 104174. [Google Scholar] [CrossRef]

- Rodriguez-Millan, M.; Garcia-Gonzalez, D.; Rusinek, A.; Arias, A. Influence of Stress State on the Mechanical Impact and Deformation Behaviors of Aluminum Alloys. Metals 2018, 8, 520. [Google Scholar] [CrossRef] [Green Version]

- Bao, Y.B.; Wierzbicki, T. On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 2004, 46, 81–98. [Google Scholar] [CrossRef]

- Skripnyak, V.V.; Skripnyak, E.G.; Skripnyak, V.A. Fracture of Titanium Alloys at High Strain Rates and under Stress Triaxiality. Metals 2020, 10, 305. [Google Scholar] [CrossRef]

- Peng, J.; Wang, Y.; Dai, Q.; Liu, L.; Liu, X.D.; Zhang, Z.H. Effect of stress triaxiality on plastic damage evolution and failure mode for 316L notched specimen. Metals 2019, 9, 1067. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Guo, Y.Z.; Qin, D.Y.; Zhou, Z.X.; Li, D.D.; Li, Y.L. Influence of stress triaxiality on the failure behavior of Ti-6Al-4V alloy under a broad range of strain rates. Theor. Appl. Fract. Mech. 2018, 97, 48–61. [Google Scholar] [CrossRef]

- Luo, Y.; Jiang, W.C.; Zhang, Y.C.; Zhou, F.; Tu, S.T. A new damage evolution model to estimate the creep fracture behavior of brazed joint under multiaxial stress. Int. J. Mech. Sci. 2018, 149, 178–189. [Google Scholar] [CrossRef]

- Kiran, R.; Khandelwal, K. A triaxiality and Lode parameter dependent ductile fracture criterion. Eng. Fract. Mech. 2014, 128, 121–138. [Google Scholar] [CrossRef]

- Liu, Z.G.; Wong, W.H.; Guo, T.F. Void behaviors from low to high triaxialities: Transition from void collapse to void coalescence. Int. J. Plast. 2016, 84, 183–202. [Google Scholar] [CrossRef]

- Lin, Y.C.; Zhu, X.H.; Dong, W.Y.; Yang, H.; Xiao, Y.W.; Kotkunde, N. Effects of deformation parameters and stress triaxiality on the fracture behaviors and microstructural evolution of an Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2020, 832, 154988. [Google Scholar] [CrossRef]

- Kondori, B.; Benzerga, A. Effect of stress triaxiality on the flow and fracture of Mg alloy AZ31. Metall. Mater. Trans. A 2014, 45, 3292–3307. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, Y.; Wang, S.X.; Palumbo, D. Influence of strain and stress triaxiality on the fracture behavior of GB 35CrMo steel during hot tensile testile. Adv. Mater. Sci. Eng. 2018, 2018, 5124524. [Google Scholar] [CrossRef] [Green Version]

- Xue, L. Damage accumulation and fracture initiation in uncracked ductile solids subject to triaxial loading. Int. J. Solids Struct. 2007, 44, 5163–5181. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.X.; Zheng, Q.L.; Zhu, J.; Li, Z.Q. Effects of Stress Triaxiality and Lode Parameter on Ductile Fracture in Aluminum Alloy. Rare Met. Mater. Eng. 2019, 48, 433–439. [Google Scholar]

- Srivastava, A.; Needleman, A. Void growth versus void collapse in a creeping single crystal. J. Mech. Phys. Solids 2013, 61, 1169–1184. [Google Scholar] [CrossRef]

- Zhu, Y.Z.; Engelhardt, M.D.; Kiran, R. Combined effects of triaxiality, Lode parameter and shear stress on void growth and coalescence. Eng. Fract. Mech. 2018, 199, 410–437. [Google Scholar] [CrossRef]

- Ma, Y.S.; Sun, D.Z.; Andrieux, F.; Zhang, K.S. Influences of initial porosity, stress triaxiality and Lode parameter on plastic deformation and ductile fracture. Acta Mech. Solida Sin. 2017, 30, 493–506. [Google Scholar] [CrossRef]

- Maysam, B.; Dirk, M. Micro-tension and micro-shear experiments to characterize stress-state dependent ductile fracture. Acta Mater. 2017, 131, 65–76. [Google Scholar]

- Anderson, D.; Winkler, S.; Bardelcik, A.; Worswick, M.J. Influence of stress triaxiality and strain rate on the failure behavior of a dual-phase DP780 steel. Mater. Des. 2014, 60, 198–207. [Google Scholar] [CrossRef]

- Malcher, L.; Morales, L.; Rodrigues, V.; Silva, V.; Araújo, L.; Ferreira, G.; Neves, R. Experimental program and numerical assessment for determination of stress triaxiality and J3 effects on AA6101-T4. Theor. Appl. Fract. Mech. 2020, 106, 102476. [Google Scholar] [CrossRef]

- Zhang, X.W.; Wen, J.F.; Zhang, X.C.; Wang, X.G.; Tu, S.T. Effects of the stress state on plastic deformation and ductile failure: Experiment and numerical simulation using a newly designed tension-shear specimen. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2079–2092. [Google Scholar] [CrossRef]

- Li, W.C.; Liao, F.F.; Zhou, T.H.; Askes, H. Ductile fracture of Q460 steel: Effects of stress triaxiality and Lode angle. J. Constr. Steel Res. 2016, 123, 1–17. [Google Scholar] [CrossRef]

- Bai, Y.L.; Wierzbicki, T. A new model of metal plasticity and fracture with pressure and Lode dependence. Int. J. Plast. 2007, 24, 1071–1096. [Google Scholar] [CrossRef]

- Wierzbicki, T.; Bao, Y.B.; Lee, Y.W.; Bai, Y.L. Calibration and evaluation of seven fracture models. Int. J. Mech. Sci. 2005, 47, 719–743. [Google Scholar] [CrossRef]

- Barsoum, I.; Faleskog, J. Rupture mechanisms in combined tension and shear-experiments. Int. J. Solids Struct. 2007, 44, 1768–1786. [Google Scholar] [CrossRef] [Green Version]

- Bai, Y.L.; Teng, X.Q.; Wierzbicki, T. On the application of stress triaxiality formula for plane strain fracture testing. J. Eng. Mater. Technol. 2009, 131, 021002. [Google Scholar] [CrossRef]

- Yu, S.Y.; Cai, L.X.; Yao, D.; Bao, C. Critical ductile fracture criterion based on first principal stress and stress triaxiality. Theor. Appl. Fract. Mech. 2020, 109, 102696. [Google Scholar] [CrossRef]

- Wierzbicki, T.; Xue, L. On the Effect of the Third Invariant of the Stress Deviator on Ductile Fracture; Technical Report; Impact and Crashworthiness Laboratory, Massachusetts Institute of Technology: Cambridge, MA, USA, 2005. [Google Scholar]

- Huang, X.W.; Ge, J.Z.; Zhao, J.; Zhao, W. A continuous damage model of Q690D steel considering the influence of Lode parameter and its application. Constr. Build. Mater. 2020, 262, 120067. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, J.; Zhou, P.; Wang, Y.; Dai, Q.; Knowles, D.; Mostafavi, M. Stress Triaxiality and Lode Angle Parameter Characterization of Flat Metal Specimen with Inclined Notch. Metals 2021, 11, 1627. https://doi.org/10.3390/met11101627

Peng J, Zhou P, Wang Y, Dai Q, Knowles D, Mostafavi M. Stress Triaxiality and Lode Angle Parameter Characterization of Flat Metal Specimen with Inclined Notch. Metals. 2021; 11(10):1627. https://doi.org/10.3390/met11101627

Chicago/Turabian StylePeng, Jian, Peishuang Zhou, Ying Wang, Qiao Dai, David Knowles, and Mahmoud Mostafavi. 2021. "Stress Triaxiality and Lode Angle Parameter Characterization of Flat Metal Specimen with Inclined Notch" Metals 11, no. 10: 1627. https://doi.org/10.3390/met11101627