Polyaniline-Supported Nickel Oxide Flower for Efficient Nitrite Electrochemical Detection in Water

Abstract

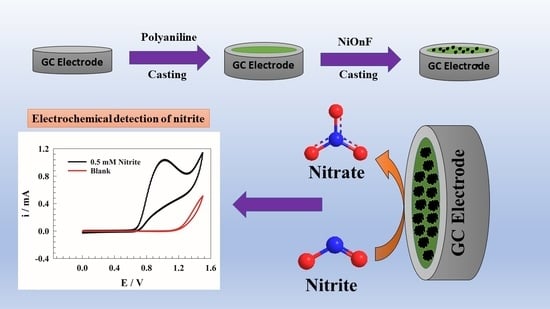

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Preparation of NiO Flowers

2.3. Preparation of PANI

2.4. Fabrication of the Electrode and Electrochemical Measurements

2.5. Characterization

3. Results and Discussion

3.1. Characterization and Analysis

3.2. Study of Electrochemical Detection of Nitrite

3.3. Effect of pH Change

3.4. Electrochemical Impedance Spectroscopy

3.5. Effect of Nitrite Ion Concentration

3.6. Interference

3.7. Real Sample Measurement

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dahle, H.K. Nitrite as a food additive. NIPH Ann. 1979, 2, 17–24. [Google Scholar] [PubMed]

- Boroujerdnia, M.; Ansari, N.A.; Dehcordie, F.S. Effect of cultivars, harvesting time and level of nitrogen fertilizer on nitrate and nitrite content, yield in Romaine lettuce. Asian J. Plant Sci. 2007, 6, 550–553. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Xu, X.; Wang, C.; Li, Z.; Li, D. A Novel Highly Sensitive Electrochemical Nitrite Sensor Based on a AuNPs/CS/Ti3C2 Nanocomposite. Nanomaterials 2022, 12, 397. [Google Scholar] [CrossRef] [PubMed]

- Picetti, R.; Deeney, M.; Pastorino, S.; Miller, M.R.; Shah, A.; Leon, D.A.; Dangour, A.D.; Green, R. Nitrate and nitrite contamination in drinking water and cancer risk: A systematic review with meta-analysis. Environ. Res. 2022, 210, 112988. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Zhao, M.; Liu, P.; Zhu, H.; Liu, B.; Hu, P.; Niu, X. Coupling diazotization with oxidase-mimetic catalysis to realize dual-mode double-ratiometric colorimetric and electrochemical sensing of nitrite. Sens. Actuators B Chem. 2022, 355, 131308. [Google Scholar] [CrossRef]

- Büldt, A.; Karst, U. Determination of nitrite in waters by microplate fluorescence spectroscopy and HPLC with fluorescence detection. Anal. Chem. 1999, 71, 3003–3007. [Google Scholar] [CrossRef]

- Hasan, M.R.; Islam, T.; Hasan, M.M.; Chowdhury, A.-N.; Ahammad, A.J.S.; Reaz, A.H.; Roy, C.K.; Shah, S.S.; Aziz, M.A. Evaluating the electrochemical detection of nitrite using a platinum nanoparticle coated jute carbon modified glassy carbon electrode and voltametric analysis. J. Phys. Chem. Solids 2022, 165, 110659. [Google Scholar] [CrossRef]

- Hefnawy, M.A.; Fadlallah, S.A.; El-Sherif, R.M.; Medany, S.S. Competition between enzymatic and non-enzymatic electrochemical determination of cholesterol. J. Electroanal. Chem. 2023, 930, 117169. [Google Scholar] [CrossRef]

- Akbari, Z.; Montazerozohori, M.; Bruno, G.; Moulaee, K.; Neri, G. Development of a novel electrochemical nitrite sensor based on Zn-Schiff base complexes. Appl. Organomet. Chem. 2022, 36, e6610. [Google Scholar] [CrossRef]

- Li, N.; Patrissi, C.J.; Che, G.; Martin, C.R. Rate Capabilities of Nanostructured LiMn2O4 Electrodes in Aqueous Electrolyte. J. Electrochem. Soc. 2000, 147, 2044. [Google Scholar] [CrossRef]

- George, J.M.; Antony, A.; Mathew, B. Metal oxide nanoparticles in electrochemical sensing and biosensing: A review. Microchim. Acta 2018, 185, 358. [Google Scholar] [CrossRef]

- Wan, Y.; Zheng, Y.F.; Zhou, B.; Song, X.C. An innovative electrochemical sensor ground on NiO nanoparticles and multi-walled carbon nanotubes for quantitative determination of nitrite. J. Nanosci. Nanotechnol. 2018, 18, 3585–3591. [Google Scholar] [CrossRef] [PubMed]

- Shabani-Nooshabadi, M.; Roostaee, M.; Tahernejad-Javazmi, F. Graphene oxide/NiO nanoparticle composite-ionic liquid modified carbon paste electrode for selective sensing of 4-chlorophenol in the presence of nitrite. J. Mol. Liq. 2020, 114687. [Google Scholar] [CrossRef]

- Sun, D.; Li, H.; Li, M.; Li, C.; Dai, H.; Sun, D.; Yang, B. Electrodeposition synthesis of a NiO/CNT/PEDOT composite for simultaneous detection of dopamine, serotonin, and tryptophan. Sens. Actuators B Chem. 2018, 259, 433–442. [Google Scholar] [CrossRef]

- Hefnawy, M.A.; Medany, S.S.; El-Sherif, R.M.; Fadlallah, S.A. NiO-MnOx/Polyaniline/Graphite Electrodes for Urea Electrocatalysis: Synergetic Effect between Polymorphs of MnOx and NiO. ChemistrySelect 2022, 7, e202103735. [Google Scholar] [CrossRef]

- Bavatharani, C.; Muthusankar, E.; Wabaidur, S.M.; Alothman, Z.A.; Alsheetan, K.M.; mana AL-Anazy, M.; Ragupathy, D. Electrospinning technique for production of polyaniline nanocomposites/nanofibres for multi-functional applications: A review. Synth. Met. 2021, 271, 116609. [Google Scholar] [CrossRef]

- Eskandari, E.; Kosari, M.; Farahani, M.H.D.A.; Khiavi, N.D.; Saeedikhani, M.; Katal, R.; Zarinejad, M. A review on polyaniline-based materials applications in heavy metals removal and catalytic processes. Sep. Purif. Technol. 2020, 231, 115901. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y.; Xie, G.; Li, J.; Wang, Y.; Liu, X.; Zang, Z. Dual Resistance and Impedance Investigation: Ultrasensitive and Stable Humidity Detection of Molybdenum Disulfide Nanosheet-Polyethylene Oxide Hybrids. ACS Appl. Mater. Interfaces 2021, 13, 25250–25259. [Google Scholar] [CrossRef]

- Duan, C.; Zheng, J. Porous coralloid Polyaniline/SnO2-based enzyme-free sensor for sensitive and selective detection of nitrite. Colloids Surfaces A Physicochem. Eng. Asp. 2019, 567, 271–277. [Google Scholar] [CrossRef]

- Chen, G.; Zheng, J. Non-enzymatic electrochemical sensor for nitrite based on a graphene oxide–polyaniline–Au nanoparticles nanocomposite. Microchem. J. 2021, 164, 106034. [Google Scholar] [CrossRef]

- Dhaoui, W.; Bouzitoun, M.; Zarrouk, H.; Ben Ouada, H.; Pron, A. Electrochemical sensor for nitrite determination based on thin films of sulfamic acid doped polyaniline deposited on Si/SiO2 structures in electrolyte/insulator/semiconductor (EIS) configuration. Synth. Met. 2008, 158, 722–726. [Google Scholar] [CrossRef]

- Sahoo, S.; Sahoo, P.K.; Sharma, A.; Satpati, A.K. Interfacial polymerized RGO/MnFe2O4/polyaniline fibrous nanocomposite supported glassy carbon electrode for selective and ultrasensitive detection of nitrite. Sens. Actuators B Chem. 2020, 309, 127763. [Google Scholar] [CrossRef]

- Hefnawy, M.A.; Medany, S.S.; El-Sherif, R.M.; Fadlallah, S.A. Green synthesis of NiO/Fe3O4@chitosan composite catalyst based on graphite for urea electro-oxidation. Mater. Chem. Phys. 2022, 290, 126603. [Google Scholar] [CrossRef]

- Li, D.; Dong, Y.; Wang, G.; Jiang, P.; Zhang, F.; Zhang, H.; Li, J.; Lyu, J.; Wang, Y.; Liu, Q. Controllable photochemical synthesis of amorphous Ni(OH)2 as hydrogen production cocatalyst using inorganic phosphorous acid as sacrificial agent. Chin. J. Catal. 2020, 41, 889–897. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, Q.; Gu, J. Effective synthesis of zeolite-encapsulated Ni nanoparticles with excellent catalytic performance for hydrogenation of CO2 to CH4. Dalt. Trans. 2020, 49, 14771–14775. [Google Scholar] [CrossRef]

- Reddy, C.; Koutavarapu, R.; Ravikumar, R.; Shim, J. A novel green-emitting Ni2+-doped Ca-Li hydroxyapatite nanopowders: Structural, optical, and photoluminescence properties. J. Mater. Sci. Mater. Electron. 2020, 31, 5097–5106. [Google Scholar] [CrossRef]

- Ji, Z.; Cen, G.; Su, C.; Liu, Y.; Zhao, Z.; Zhao, C.; Mai, W. All-Inorganic Perovskite Photodetectors with Ultrabroad Linear Dynamic Range for Weak-Light Imaging Applications. Adv. Opt. Mater. 2020, 8, 2001436. [Google Scholar] [CrossRef]

- Shaw, S.K.; Gangwar, A.; Sharma, A.; Alla, S.K.; Kavita, S.; Vasundhara, M.; Meena, S.S.; Maiti, P.; Prasad, N.K. Structural and magnetic properties of nanocrystalline equi-atomic spinel high-entropy oxide (AlCoFeMnNi)3O4 synthesised by microwave assisted co-precipitation technique. J. Alloys Compd. 2021, 878, 160269. [Google Scholar] [CrossRef]

- Du, H.; Ding, F.; Zhao, J.; Zhang, X.; Li, Y.; Zhang, Y.; Li, J.; Yang, X.; Li, K.; Yang, Y. Core-shell structured Ni3S2@VO2 nanorods grown on nickel foam as battery-type materials for supercapacitors. Appl. Surf. Sci. 2020, 508, 144876. [Google Scholar] [CrossRef]

- Jia, C.; Zhang, Y.; Kong, Q.; Wang, Q.; Chen, G.; Guam, H.; Dong, C. Soft-template synthesis of mesoporous NiFe2O4 for highly sensitive acetone detection. J. Mater. Sci. Mater. Electron. 2020, 31, 6000–6007. [Google Scholar] [CrossRef]

- He, L.; Hong, T.; Hong, X.; Liao, X.; Chen, Y.; Zhang, W.; Liu, H.; Luo, W.; Mai, L. Ultrastable High-Energy On-Chip Nickel–Bismuth Microbattery Powered by Crystalline Bi Anode and Ni–Co Hydroxide Cathode. Energy Technol. 2019, 7, 1900144. [Google Scholar] [CrossRef]

- Senthilkumar, V.; Kadumudi, F.B.; Ho, N.T.; Kim, J.-W.; Park, S.; Bae, J.-S.; Choi, W.M.; Cho, S.; Kim, Y.S. NiO nanoarrays of a few atoms thickness on 3D nickel network for enhanced pseudocapacitive electrode applications. J. Power Sources 2016, 303, 363–371. [Google Scholar] [CrossRef]

- Guo, M.; Ye, L.; Zhao, L. Solid-state-grinding method to synthesize NiCoFe alloy/NiCoFe–OH nanosheets for asymmetric supercapacitor. J. Alloys Compd. 2021, 850, 156787. [Google Scholar] [CrossRef]

- Ding, C.; Gao, W.; Zhao, Y.; Zhao, Y.; Zhou, H.; Li, J.; Jin, H. Effects of Co2+ doping on physicochemical behaviors of hierarchical NiO nanostructure. Appl. Surf. Sci. 2016, 390, 890–896. [Google Scholar] [CrossRef]

- Liang, Y.-C.; Xu, N.-C.; Chiang, K.-J. Surface Morphology-Dependent Functionality of Titanium Dioxide–Nickel Oxide Nanocomposite Semiconductors. Nanomaterials 2019, 9, 1651. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.-C.; Yang, C.-F. Investigation of the properties of nanostructured Li-doped NiO films using the modified spray pyrolysis method. Nanoscale Res. Lett. 2013, 8, 33. [Google Scholar] [CrossRef] [Green Version]

- Tian, J.; Shao, Q.; Dong, X.; Zheng, J.; Pan, D.; Zhang, X.; Cao, H.; Hao, L.; Liu, J.; Mai, X. Bio-template synthesized NiO/C hollow microspheres with enhanced Li-ion battery electrochemical performance. Electrochim. Acta 2018, 261, 236–245. [Google Scholar] [CrossRef]

- Shirsath, S.E.; Liu, X.; Yasukawa, Y.; Li, S.; Morisako, A. Switching of magnetic easy-axis using crystal orientation for large perpendicular coercivity in CoFe2O4 thin film. Sci. Rep. 2016, 6, 30074. [Google Scholar] [CrossRef] [Green Version]

- Jain, S.; Shah, J.; Negi, N.S.; Sharma, C.; Kotnala, R.K. Significance of interface barrier at electrode of hematite hydroelectric cell for generating ecopower by water splitting. Int. J. Energy Res. 2019, 43, 4743–4755. [Google Scholar] [CrossRef]

- Kwoka, M.; Kulis-Kapuscinska, A.; Zappa, D.; Comini, E.; Szuber, J. Novel insight on the local surface properties of ZnO nanowires. Nanotechnology 2020, 31, 465705. [Google Scholar] [CrossRef]

- Rameshan, C.; Ng, M.L.; Shavorskiy, A.; Newberg, J.T.; Bluhm, H. Water adsorption on polycrystalline vanadium from ultra-high vacuum to ambient relative humidity. Surf. Sci. 2015, 641, 141–147. [Google Scholar] [CrossRef] [Green Version]

- Han, C.; Zhu, J.; Fu, K.; Deng, D.; Luo, W.; Mai, L. A high-capacity polyaniline-intercalated layered vanadium oxide for aqueous ammonium-ion batteries. Chem. Commun. 2022, 58, 791–794. [Google Scholar] [CrossRef] [PubMed]

- Altıncı, O.C.; Körbahti, B.K. Graphene oxide-polyaniline conducting composite film deposited on platinum-iridium electrode by electrochemical polymerization of aniline: Synthesis and environmental electrochemistry application. Appl. Surf. Sci. Adv. 2022, 7, 100212. [Google Scholar] [CrossRef]

- Gholami, H.; Shakeri, A.; Saadattalab, V. Investigation of physical and mechanical properties of polyaniline/MMT nanocomposites. Curr. Chem. Lett. 2017, 6, 151–158. [Google Scholar] [CrossRef]

- Gabris, M.A.; Rezania, S.; Rafieizonooz, M.; Khankhaje, E.; Devanesan, S.; AlSalhi, M.S.; Aljaafreh, M.J.; Shadravan, A. Chitosan magnetic graphene grafted polyaniline doped with cobalt oxide for removal of Arsenic(V) from water. Environ. Res. 2022, 207, 112209. [Google Scholar] [CrossRef]

- Sivakumar, M.; Sakthivel, M.; Chen, S.-M.; Pandi, K.; Chen, T.-W.; Yu, M.-C. An electrochemical selective detection of nitrite sensor for polyaniline doped graphene oxide modified electrode. Int. J. Electrochem. Sci. 2017, 12, 4835–4846. [Google Scholar] [CrossRef]

- Guo, M.; Chen, J.; Li, J.; Tao, B.; Yao, S. Fabrication of polyaniline/carbon nanotube composite modified electrode and its electrocatalytic property to the reduction of nitrite. Anal. Chim. Acta 2005, 532, 71–77. [Google Scholar] [CrossRef]

- Hammer, B.; Hansen, L.B.; Nørskov, J.K. Improved adsorption energetics within density-functional theory using revised Perdew-Burke-Ernzerhof functionals. Phys. Rev. B 1999, 59, 7413. [Google Scholar] [CrossRef] [Green Version]

- Clark, S.J.; Segall, M.D.; Pickard, C.J.; Hasnip, P.J.; Probert, M.I.J.; Refson, K.; Payne, M.C. First principles methods using CASTEP. Z. Für Krist. Mater. 2005, 220, 567–570. [Google Scholar] [CrossRef] [Green Version]

- Hefnawy, M.A.; Fadlallah, S.A.; El-Sherif, R.M.; Medany, S.S. Systematic DFT studies of CO-Tolerance and CO oxidation on Cu-doped Ni surfaces. J. Mol. Graph. Model. 2023, 118, 108343. [Google Scholar] [CrossRef]

- Hefnawy, M.A.; Fadlallah, S.A.; El-Sherif, R.M.; Medany, S.S. Synergistic effect of Cu-doped NiO for enhancing urea electrooxidation: Comparative electrochemical and DFT studies. J. Alloys Compd. 2022, 896, 162857. [Google Scholar] [CrossRef]

- Hefnawy, M.A.; Fadlallah, S.A.; El-Sherif, R.M.; Medany, S.S. Nickel-manganese double hydroxide mixed with reduced graphene oxide electrocatalyst for efficient ethylene glycol electrooxidation and hydrogen evolution reaction. Synth. Met. 2021, 282, 116959. [Google Scholar] [CrossRef]

- Eliwa, A.S.; Hefnawy, M.A.; Medany, S.S.; Deghadi, R.G.; Hosny, W.M.; Mohamed, G.G. Ultrasonic-assisted synthesis of nickel metal-organic framework for efficient urea removal and water splitting applications. Synth. Met. 2023, 294, 117309. [Google Scholar] [CrossRef]

- Galal, A.; Atta, N.F.; Hefnawy, M.A. Lanthanum nickel oxide nano-perovskite decorated carbon nanotubes/poly (aniline) composite for effective electrochemical oxidation of urea. J. Electroanal. Chem. 2020, 862, 114009. [Google Scholar] [CrossRef]

- Galal, A.; Atta, N.F.; Hefnawy, M.A. Voltammetry study of electrocatalytic activity of lanthanum nickel perovskite nanoclusters-based composite catalyst for effective oxidation of urea in alkaline medium. Synth. Met. 2020, 266, 116372. [Google Scholar] [CrossRef]

- Abdel Hameed, R.M.; Medany, S.S. Evaluation of core-shell structured cobalt@platinum nanoparticles-decorated graphene for nitrite sensing. Synth. Met. 2019, 247, 67–80. [Google Scholar] [CrossRef]

- Lü, H.; Wang, H.; Yang, L.; Zhou, Y.; Xu, L.; Hui, N.; Wang, D. A sensitive electrochemical sensor based on metal cobalt wrapped conducting polymer polypyrrole nanocone arrays for the assay of nitrite. Microchim. Acta 2022, 189, 26. [Google Scholar] [CrossRef]

- Saeb, E.; Asadpour-Zeynali, K. A novel ZIF-8@ZIF-67/Au core–shell metal organic framework nanocomposite as a highly sensitive electrochemical sensor for nitrite determination. Electrochim. Acta 2022, 417, 140278. [Google Scholar] [CrossRef]

- Atta, N.F.; El-Sherif, R.M.A.; Hassan, H.K.; Hefnawy, M.A.; Galal, A. Conducting Polymer-Mixed Oxide Composite Electrocatalyst for Enhanced Urea Oxidation. J. Electrochem. Soc. 2018, 165, J3310–J3317. [Google Scholar] [CrossRef]

- Hefnawy, M.A.; Medany, S.S.; Fadlallah, S.A.; El-Sherif, R.M.; Hassan, S.S. Novel Self-assembly Pd(II)-Schiff Base Complex Modified Glassy Carbon Electrode for Electrochemical Detection of Paracetamol. Electrocatalysis 2022, 13, 598–610. [Google Scholar] [CrossRef]

- Hefnawy, M.A.; Nafady, A.; Mohamed, S.K.; Medany, S.S. Facile green synthesis of Ag/carbon nanotubes composite for efficient water splitting applications. Synth. Met. 2023, 294, 117310. [Google Scholar] [CrossRef]

- Hefnawy, M.A.; Medany, S.S.; El-Sherif, R.M.; El-Bagoury, N.; Fadlallah, S.A. High-performance IN738 superalloy derived from turbine blade waste for efficient ethanol, ethylene glycol, and urea electrooxidation. J. Appl. Electrochem. 2023. [Google Scholar] [CrossRef]

- Laviron, E. Adsorption, autoinhibition and autocatalysis in polarography and in linear potential sweep voltammetry. J. Electroanal. Chem. Interfacial Electrochem. 1974, 52, 355–393. [Google Scholar] [CrossRef]

- Allen, J.B.; Larry, R.F. Electrochemical Methods Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Döner, A.; Telli, E.; Kardaş, G. Electrocatalysis of Ni-promoted Cd coated graphite toward methanol oxidation in alkaline medium. J. Power Sources 2012, 205, 71–79. [Google Scholar] [CrossRef]

- Zhe, T.; Li, M.; Li, F.; Li, R.; Bai, F.; Bu, T.; Jia, P.; Wang, L. Integrating electrochemical sensor based on MoO3/Co3O4 heterostructure for highly sensitive sensing of nitrite in sausages and water. Food Chem. 2022, 367, 130666. [Google Scholar] [CrossRef]

- Moradi, A.H.; Dehghan, P.; Alipour, E.; Divband, B.; Akbari, A.; Khezerlou, A. Detection of nitrite using a novel electrochemical sensor based on palladium/zinc oxide/ graphene oxide nanocomposite. Int. J. Environ. Anal. Chem. 2022, 1–16. [Google Scholar] [CrossRef]

- Yang, Q.; Chen, N.; Zhang, Y.; Ye, Z.; Yang, Y. Construction of La2O3-CeO2 Composites Modified Glassy Carbon Electrode as a Novel Electrochemical Sensor for Sensitive Detection of Nitrite. Chem. Lett. 2022, 51, 435–439. [Google Scholar] [CrossRef]

- Yang, Y.; Lei, Q.; Li, J.; Hong, C.; Zhao, Z.; Xu, H.; Hu, J. Synthesis and enhanced electrochemical properties of AuNPs@ MoS2/rGO hybrid structures for highly sensitive nitrite detection. Microchem. J. 2022, 172, 106904. [Google Scholar] [CrossRef]

- Salagare, S.; Adarakatti, P.S.; Venkataramanappa, Y.; Almalki, A.S.A. Electrochemical nitrite sensing employing palladium oxide–reduced graphene oxide (PdO-RGO) nanocomposites: Application to food and environmental samples. Ionics 2022, 28, 927–938. [Google Scholar] [CrossRef]

- Cheng, Z.; Song, H.; Zhang, X.; Cheng, X.; Xu, Y.; Zhao, H.; Gao, S.; Huo, L. Morphology control of ZnO by adjusting the solvent and non-enzymatic nitrite ions electrochemical sensor constructed with stir bar-shaped ZnO/Nafion nanocomposite. Sens. Actuators B Chem. 2021, 346, 130525. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, J.; Gong, J.; Wu, W.-P.; Bao, N.; Pan, Z.-Q.; Gu, H.-Y. The investigation of electrochemical properties for Fe3O4@Pt nanocomposites and an enhancement sensing for nitrite. Electrochim. Acta 2013, 111, 876–887. [Google Scholar] [CrossRef]

- Heli, H.; Eskandari, I.; Sattarahmady, N.; Moosavi-Movahedi, A.A. Cobalt nanoflowers: Synthesis, characterization and derivatization to cobalt hexacyanoferrate—Electrocatalytic oxidation and determination of sulfite and nitrite. Electrochim. Acta 2012, 77, 294–301. [Google Scholar] [CrossRef]

- Afkhami, A.; Madrakian, T.; Ghaedi, H.; Khanmohammadi, H. Construction of a chemically modified electrode for the selective determination of nitrite and nitrate ions based on a new nanocomposite. Electrochim. Acta 2012, 66, 255–264. [Google Scholar] [CrossRef]

| pH | Diffusion Coefficient/D (cm2 s−1) | Transfer Coefficient/α | Onset Potential (mV) | Ep (mV) | Ip (mA) |

|---|---|---|---|---|---|

| 2 | 1.97 10−7 | 0.307 | 0.714 | 1.08 | 0.392 |

| 4 | 3.30 10−7 | 0.401 | 0.691 | 1.04 | 0.636 |

| 6 | 4.27 10−7 | 0.425 | 0.686 | 1.05 | 0.841 |

| 7 | 4.91 10−7 | 0.596 | 0.682 | 1.04 | 1.023 |

| 8 | 3.75 10−7 | 0.716 | 0.661 | 0.91 | 0.832 |

| 10 | 2.02 10−7 | 0.813 | 0.654 | 0.86 | 0.771 |

| pH | Element | Rs | Rc | Q1 | R2 | Q2 | W | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Unit | Ω | Ω | Y0 | n | Ω | Y0 | m | mMho s1/2 | χ² | |

| 2 | 20.04 | 840.76 | 3.35 10−6 | 0.868 | 1283.27 | 8.45 10−5 | 0.670 | 0.0383 | ||

| 4 | 23.51 | 1385.41 | 7.06 10−6 | 0.667 | 707.28 | 2.74 10−6 | 0.867 | 0.0436 | ||

| 6 | 26.11 | 383.99 | 2.09 10−6 | 0.853 | 928.50 | 4.58 10−5 | 0.864 | 0.0278 | ||

| 7 | 23.56 | 224.70 | 5.93 10−6 | 0.895 | 880.35 | 18.7 10−5 | 0.0231 | |||

| 8 | 14.13 | 356.49 | 9.61 10−6 | 0.914 | 601.79 | 7.15 10−5 | 0.0602 | |||

| 10 | 19.318 | 496.52 | 2.83 10−5 | 0.897 | 3527.36 | 2.14 10−5 | 0.0478 | |||

| Electrode | Linear Detection Range (µM) | Limit of Detection (µM) | Method | Reference |

|---|---|---|---|---|

| MoO3/Co3O4 | 0.3125–4514 | 0.075 | Amperometry | [66] |

| Zn-Schiff base | 2–4838 | 0.78 | Amperometry | [9] |

| palladium/zinc oxide/graphene oxide | 3.17–1111 | 2.39 | Amperometry | [67] |

| La2O3-CeO2 | 0.25–4000 | 0.015 | Amperometry | [68] |

| AuNPs@MoS2/rGO | 0.2–2600 | 0.038 | Amperometry | [69] |

| PdO-RGO | 10–1500 | 10.14 | differential pulse voltammetry | [70] |

| ZnO/Nafion | 0.3–6140 | 0.21 | Amperometry | [71] |

| Fe3O4@Pt | 21.1–13,000 | 0.109 | Amperometry | [72] |

| Cobalt nanoflowers | 100–2150 | 1.2 | Amperometry | [73] |

| SiO2@Fe3O4 | 0.72–110 | 0.74 | Amperometry | [74] |

| GC/PANI/NiOnF | 0.1–1 | 0.0097 | Amperometry | This work |

| GC/PANI/NiOnF | 1–500 | 0.064 | Amperometry | This work |

| Concentration of Nitrite Added (μM) | Concentration of Nitrite Found (μM) | Recovery (%) |

|---|---|---|

| 40 | 42.3 | 105.75 |

| 100 | 103 | 103 |

| 150 | 160 | 106.4 |

| 180 | 194 | 107.8 |

| 220 | 216 | 98.2 |

| 240 | 231 | 96.25 |

| 260 | 265 | 101.9 |

| 280 | 272 | 97.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Kadhi, N.S.; Hefnawy, M.A.; Alamro, F.S.; Pashameah, R.A.; Ahmed, H.A.; Medany, S.S. Polyaniline-Supported Nickel Oxide Flower for Efficient Nitrite Electrochemical Detection in Water. Polymers 2023, 15, 1804. https://doi.org/10.3390/polym15071804

Al-Kadhi NS, Hefnawy MA, Alamro FS, Pashameah RA, Ahmed HA, Medany SS. Polyaniline-Supported Nickel Oxide Flower for Efficient Nitrite Electrochemical Detection in Water. Polymers. 2023; 15(7):1804. https://doi.org/10.3390/polym15071804

Chicago/Turabian StyleAl-Kadhi, Nada S., Mahmoud A. Hefnawy, Fowzia S. Alamro, Rami Adel Pashameah, Hoda A. Ahmed, and Shymaa S. Medany. 2023. "Polyaniline-Supported Nickel Oxide Flower for Efficient Nitrite Electrochemical Detection in Water" Polymers 15, no. 7: 1804. https://doi.org/10.3390/polym15071804