Potentially Health-Promoting Spaghetti-Type Pastas Based on Doubly Modified Corn Starch: Starch Oxidation via Wet Chemistry Followed by Organocatalytic Butyrylation Using Reactive Extrusion

Abstract

:1. Introduction

2. Experimental Method

2.1. Materials

2.2. Starch Oxidation

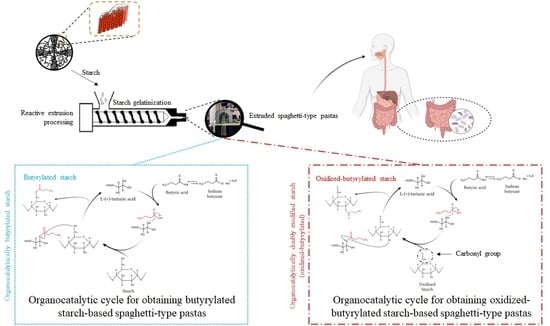

2.3. Formulation and Manufacture of the Spaghetti-Type Pastas

2.4. Spaghetti-Type Pasta Characterizations

2.4.1. Solid-State 13C CP MAS NMR Spectroscopy

2.4.2. Determination of DS by Butyrylation

2.4.3. ATR/FTIR Spectroscopy

2.4.4. Scanning Electron Microscopy (SEM)

2.4.5. XRD

2.4.6. TGA

2.4.7. Pancreatic Digestion and Free Butyrate (Bu) Content Analysis

2.4.8. In Vitro Starch Digestibility

2.5. Statistical Analysis

3. Results and Discussion

3.1. Structural Analysis: 13C CP MAS NMR, DS, ATR/FTIR, SEM, XRD and TGA

3.2. Digestibility Analysis: Pancreatic Digestion, Free Butyrate (Bu) Content and In Vitro Starch Digestibility

4. Conclusions

- The butyrylation reaction apparently occurred on the amorphous regions of the starch (amylose), regardless of the starch used: native or oxidized starch, thus resulting in more crystalline pasta systems, in which their thermal resistance was reduced, due to the breaking of the starch–starch H-bonding interactions provoked by the esterification reaction of hydrophobic Bu groups on the starch structure.

- The oxidation reaction led to the production of more amorphous and thermal degradation-resistant spaghetti-type pasta systems compared to native starch (NSt)-based pasta systems. Regardless, the enzymatic resistance by α-amylase was lower in the oxidized starch (OSt)-based pasta system compared to the NSt-based pasta system, thus reducing RS values. Noteworthily, DS values by butyrylation were inferior in the OSt-based pasta system compared to the NSt-based pasta system in the absence of the organocatalyst. This suggests that the sites with the potential to be esterified (available -OH groups on the starch structure) were previously occupied (oxidized) by carbonyl (C=O) and carboxyl (O−C=O) groups.

- The addition of the organocatalyst (TAc) had a positive result on the increase of the DS values by butyrylation in the OSt-based pasta system, which caused increases in RS values in this pasta system made from doubly modified (oxidized-butyrylated) starch (starch oxidation via wet chemistry followed by organocatalytic butyrylation) and reduction of the free butyrate content values. Therefore, potentially health-promoting spaghetti-type pastas were prepared from organocatalytically doubly modified (oxidized-butyrylated) starch. Nevertheless, an opposite trend was observed once the organocatalyst was added to the NSt-based pasta systems. These findings suggest that organocatalyst–amylose hydrogen bonding interactions could limit the butyrylation reaction.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Patiño-Rodríguez, O.; Bello-Pérez, L.A.; Flores-Silva, P.C.; Sánchez-Rivera, M.M.; Romero-Bastida, C.A. Physicochemical Properties and Metabolomic Profile of Gluten-Free Spaghetti Prepared with Unripe Plantain Flours. LWT 2018, 90, 297–302. [Google Scholar] [CrossRef]

- Federación de Asociaciones de Celiacos de España (FACE) Enfermedad Celíaca. Available online: https://celiacos.org/enfermedad-celiaca/que-es-el-gluten/ (accessed on 14 January 2022).

- Elli, L.; Ferretti, F.; Orlando, S.; Vecchi, M.; Monguzzi, E.; Roncoroni, L.; Schuppan, D. Management of Celiac Disease in Daily Clinical Practice. Eur. J. Intern. Med. 2019, 61, 15–24. [Google Scholar] [CrossRef]

- Bianchi, M.-L.; Bardella, M.T. Bone in Celiac Disease. Osteoporos. Int. 2008, 19, 1705–1716. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Mendieta, J.R.; Ortega-Toro, R. In-Depth Study from Gluten/PCL-Based Food Packaging Films Obtained under Reactive Extrusion Conditions Using Chrome Octanoate as a Potential Food Grade Catalyst. Food Hydrocoll. 2021, 111, 106255. [Google Scholar] [CrossRef]

- Ralbovsky, N.M.; Lednev, I.K. Analysis of Individual Red Blood Cells for Celiac Disease Diagnosis. Talanta 2021, 221, 121642. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, T.J. Plantain Flours as Potential Raw Materials for the Development of Gluten-Free Functional Foods. Carbohydr. Polym. 2018, 202, 265–279. [Google Scholar] [CrossRef] [PubMed]

- Gómez, M.; Román, L. Role of Different Polymers on the Development of Gluten-Free Baked Goods. In Polymers for Food Applications; Gutiérrez, T.J., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 693–724. ISBN 978-3-319-94625-2. [Google Scholar]

- Patiño-Rodríguez, O.; Agama-Acevedo, E.; Pacheco-Vargas, G.; Alvarez-Ramirez, J.; Bello-Pérez, L.A. Physicochemical, Microstructural and Digestibility Analysis of Gluten-Free Spaghetti of Whole Unripe Plantain Flour. Food Chem. 2019, 298, 125085. [Google Scholar] [CrossRef]

- Bresciani, A.; Giordano, D.; Vanara, F.; Blandino, M.; Marti, A. High-Amylose Corn in Gluten-Free Pasta: Strategies to Deliver Nutritional Benefits Ensuring the Overall Quality. Food Chem. 2021, 353, 129489. [Google Scholar] [CrossRef]

- Johnson, S.K.; Kaur, G.; Luitel, S.; Hoang, L.A.P.; Bhattarai, R.R. Replacement of Buckwheat by Black Sorghum Flour on Soba-Type Noodles. Int. J. Food Sci. Technol. 2021, 56, 5861–5870. [Google Scholar] [CrossRef]

- Salama, M.; Mu, T.; Sun, H. Influence of Sweet Potato Flour on the Microstructure and Nutritional Quality of Gluten-Free Fresh Noodles. Int. J. Food Sci. Technol. 2021, 56, 3938–3947. [Google Scholar] [CrossRef]

- Sigüenza-Andrés, T.; Gallego, C.; Gómez, M. Can Cassava Improve the Quality of Gluten Free Breads? LWT 2021, 149, 111923. [Google Scholar] [CrossRef]

- Torra, M.; Belorio, M.; Ayuso, M.; Carocho, M.; Ferreira, I.C.F.R.; Barros, L.; Gómez, M. Chickpea and Chestnut Flours as Non-Gluten Alternatives in Cookies. Foods 2021, 10, 911. [Google Scholar] [CrossRef] [PubMed]

- Shen, S.; Chi, C.; Zhang, Y.; Li, L.; Chen, L.; Li, X. New Insights into How Starch Structure Synergistically Affects the Starch Digestibility, Texture, and Flavor Quality of Rice Noodles. Int. J. Biol. Macromol. 2021, 184, 731–738. [Google Scholar] [CrossRef] [PubMed]

- Agama-Acevedo, E.; Bello-Pérez, L.A.; Pacheco-Vargas, G.; Nuñez-Santiago, M.C.; Evangelista-Lozano, S.; Gutiérrez, T.J. Starches Isolated from the Pulp and Seeds of Unripe Pouteria campechiana Fruits as Potential Health-Promoting Food Additives. Starch—Stärke 2023, 75, 2200089. [Google Scholar] [CrossRef]

- Chi, C.; Li, X.; Zhang, Y.; Chen, L.; Li, L.; Miao, S. Progress in Tailoring Starch Intrinsic Structures to Improve Its Nutritional Value. Food Hydrocoll. 2021, 113, 106447. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Tovar, J. Medicinal Foods. Curr. Pharm. Des. 2019, 25, 3417. [Google Scholar] [CrossRef]

- Lehmann, U.; Robin, F. Slowly Digestible Starch—Its Structure and Health Implications: A Review. Trends Food Sci. Technol. 2007, 18, 346–355. [Google Scholar] [CrossRef]

- Toro-Márquez, L.A.; Merino, D.; Gutiérrez, T.J. Bionanocomposite Films Prepared from Corn Starch with and without Nanopackaged Jamaica (Hibiscus Sabdariffa) Flower Extract. Food Bioprocess Technol. 2018, 11, 1955–1973. [Google Scholar] [CrossRef] [Green Version]

- Gutiérrez, T.J.; Tovar, J. Update of the Concept of Type 5 Resistant Starch (RS5): Self-Assembled Starch V-Type Complexes. Trends Food Sci. Technol. 2021, 109, 711–724. [Google Scholar] [CrossRef]

- Ashogbon, A.O. Dual Modification of Various Starches: Synthesis, Properties and Applications. Food Chem. 2021, 342, 128325. [Google Scholar] [CrossRef]

- Vanier, N.L.; El Halal, S.L.M.; Dias, A.R.G.; da Rosa Zavareze, E. Molecular Structure, Functionality and Applications of Oxidized Starches: A Review. Food Chem. 2017, 221, 1546–1559. [Google Scholar] [CrossRef] [PubMed]

- Chung, H.-J.; Shin, D.-H.; Lim, S.-T. In Vitro Starch Digestibility and Estimated Glycemic Index of Chemically Modified Corn Starches. Food Res. Int. 2008, 41, 579–585. [Google Scholar] [CrossRef]

- Dupuis, J.H.; Liu, Q.; Yada, R.Y. Methodologies for Increasing the Resistant Starch Content of Food Starches: A Review. Compr. Rev. Food Sci. Food Saf. 2014, 13, 1219–1234. [Google Scholar] [CrossRef]

- An, H.-J. Effects of Ozonation and Addition of Amino Acids on Properties of Rice Starches. Ph.D. Thesis, Louisiana State University, Baton Rouge, LA, USA, 2005. [Google Scholar]

- Ragavan, K.V.; Hernandez-Hernandez, O.; Martinez, M.M.; Gutiérrez, T.J. Organocatalytic Esterification of Polysaccharides for Food Applications: A Review. Trends Food Sci. Technol. 2022, 119, 45–56. [Google Scholar] [CrossRef]

- Annison, G.; Illman, R.J.; Topping, D.L. Acetylated, Propionylated or Butyrylated Starches Raise Large Bowel Short-Chain Fatty Acids Preferentially When Fed to Rats. J. Nutr. 2003, 133, 3523–3528. [Google Scholar] [CrossRef] [Green Version]

- Tupa, M.V.; Arroyo, S.; Herrera, M.L.; Foresti, M.L. Production of Esterified Starches with Increased Resistant Starch Content by an α-Hydroxy Acid-Catalyzed Route. Starch—Stärke 2018, 70, 1700155. [Google Scholar] [CrossRef]

- Nielsen, T.S.; Bendiks, Z.; Thomsen, B.; Wright, M.E.; Theil, P.K.; Scherer, B.L.; Marco, M.L. High-Amylose Maize, Potato, and Butyrylated Starch Modulate Large Intestinal Fermentation, Microbial Composition, and Oncogenic MiRNA Expression in Rats Fed a High-Protein Meat Diet. Int. J. Mol. Sci. 2019, 20, 2137. [Google Scholar] [CrossRef] [Green Version]

- Clarke, J.M.; Young, G.P.; Topping, D.L.; Bird, A.R.; Cobiac, L.; Scherer, B.L.; Winkler, J.G.; Lockett, T.J. Butyrate Delivered by Butyrylated Starch Increases Distal Colonic Epithelial Apoptosis in Carcinogen-Treated Rats. Carcinogenesis 2012, 33, 197–202. [Google Scholar] [CrossRef]

- Imre, B.; Vilaplana, F. Organocatalytic Esterification of Corn Starches towards Enhanced Thermal Stability and Moisture Resistance. Green Chem. 2020, 22, 5017–5031. [Google Scholar] [CrossRef]

- Shih, M.-K.; Tain, Y.-L.; Chen, Y.-W.; Hsu, W.-H.; Yeh, Y.-T.; Chang, S.K.C.; Liao, J.-X.; Hou, C.-Y. Resveratrol Butyrate Esters Inhibit Obesity Caused by Perinatal Exposure to Bisphenol A in Female Offspring Rats. Molecules 2021, 26, 4010. [Google Scholar] [CrossRef]

- Hernandez-Hernandez, O.; Julio-Gonzalez, L.C.; Doyagüez, E.G.; Gutiérrez, T.J. Structure-Digestibility Relationship from Noodles Based on Organocatalytically Esterified Regular and Waxy Corn Starch Obtained by Reactive Extrusion Using Sodium Propionate. Food Hydrocoll. 2022, 131, 107825. [Google Scholar] [CrossRef]

- Hamer, H.M.; Jonkers, D.M.A.E.; Bast, A.; Vanhoutvin, S.A.L.W.; Fischer, M.A.J.G.; Kodde, A.; Troost, F.J.; Venema, K.; Brummer, R.-J.M. Butyrate Modulates Oxidative Stress in the Colonic Mucosa of Healthy Humans. Clin. Nutr. 2009, 28, 88–93. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Lin, Y.; Liu, L.; Zheng, B.; Zhang, Y.; Zeng, H. Effect of Lotus Seed Resistant Starch on Lactic Acid Conversion to Butyric Acid Fermented by Rat Fecal Microbiota. J. Agric. Food Chem. 2022, 70, 1525–1535. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Shi, L.; Qi, Y.; Wang, Q.; Zhao, J.; Zhang, H.; Wang, G.; Chen, W. Butylated Starch Alleviates Polycystic Ovary Syndrome by Stimulating the Secretion of Peptide Tyrosine-Tyrosine and Regulating Faecal Microbiota. Carbohydr. Polym. 2022, 287, 119304. [Google Scholar] [CrossRef]

- Wang, M.; Wichienchot, S.; He, X.; Fu, X.; Huang, Q.; Zhang, B. In Vitro Colonic Fermentation of Dietary Fibers: Fermentation Rate, Short-Chain Fatty Acid Production and Changes in Microbiota. Trends Food Sci. Technol. 2019, 88, 1–9. [Google Scholar] [CrossRef]

- Nielsen, T.; Canibe, N.; Larsen, F. Butyrylation of Maize and Potato Starches and Characterization of the Products by Nuclear Magnetic Resonance and In Vitro Fermentation. Foods 2018, 7, 79. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Wang, J.; Wang, F.; Wu, M.; Wang, R.; Strappe, P.; Blanchard, C.; Zhou, Z. Insights into the Multi-Scale Structure of Wheat Starch Following Acylation: Physicochemical Properties and Digestion Characteristics. Food Hydrocoll. 2022, 124, 107347. [Google Scholar] [CrossRef]

- Li, L.; Li, W.; Yang, L.; Cheng, L.; Li, Z.; Li, C.; Hong, Y.; Gu, Z. Butyl Group Distribution, Intestinal Digestion, and Colonic Fermentation Characteristics of Different Butyrylated Starches. J. Agric. Food Chem. 2022, 70, 3289–3299. [Google Scholar] [CrossRef]

- Ye, J.; Luo, S.; Huang, A.; Chen, J.; Liu, C.; McClements, D.J. Synthesis and Characterization of Citric Acid Esterified Rice Starch by Reactive Extrusion: A New Method of Producing Resistant Starch. Food Hydrocoll. 2019, 92, 135–142. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Valencia, G.A. Reactive Extrusion-Processed Native and Phosphated Starch-Based Food Packaging Films Governed by the Hierarchical Structure. Int. J. Biol. Macromol. 2021, 172, 439–451. [Google Scholar] [CrossRef]

- Herniou--Julien, C.; Gutiérrez, T.J. Reactive Extrusion-Processed Shape-Memory Food Packaging Films Made from Native and Carboxymethylated Plantain Flour/Polystyrene Blends. Starch—Stärke 2021, 73, 2100053. [Google Scholar] [CrossRef]

- Miladinov, V.D.; Hanna, M.A. Starch Esterification by Reactive Extrusion. Ind. Crops Prod. 2000, 11, 51–57. [Google Scholar] [CrossRef]

- United States Food and Drug Administration (USFDA) Substances Generally Recognized as Safe. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=582.1099 (accessed on 15 January 2022).

- Gutiérrez, T.J.; Alvarez, V.A. Properties of Native and Oxidized Corn Starch/Polystyrene Blends under Conditions of Reactive Extrusion Using Zinc Octanoate as a Catalyst. React. Funct. Polym. 2017, 112, 33–44. [Google Scholar] [CrossRef]

- Yi, X.; Zhang, S.; Ju, B. Preparation of Water-Soluble Oxidized Starch with High Carbonyl Content by Sodium Hypochlorite. Starch—Stärke 2014, 66, 115–123. [Google Scholar] [CrossRef]

- Tupa, M.; Maldonado, L.; Vázquez, A.; Foresti, M.L. Simple Organocatalytic Route for the Synthesis of Starch Esters. Carbohydr. Polym. 2013, 98, 349–357. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, T.J.; Alvarez, V.A. Bionanocomposite Films Developed from Corn Starch and Natural and Modified Nano-Clays with or without Added Blueberry Extract. Food Hydrocoll. 2018, 77, 407–420. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Wang, F.; Wang, J.; Wang, R.; Strappe, P.; Zheng, B.; Zhou, Z.; Chen, L. Manipulation of the Internal Structure of Starch by Propionyl Treatment and Its Diverse Influence on Digestion and In Vitro Fermentation Characteristics. Carbohydr. Polym. 2021, 270, 118390. [Google Scholar] [CrossRef]

- Englyst, H.N.; Kingman, S.M.; Cummings, J.H. Classification and Measurement of Nutritionally Important Starch Fractions. Eur. J. Clin. Nutr. 1992, 46, S33–S50. [Google Scholar]

- Volant, C.; Gilet, A.; Beddiaf, F.; Collinet-Fressancourt, M.; Falourd, X.; Descamps, N.; Wiatz, V.; Bricout, H.; Tilloy, S.; Monflier, E.; et al. Multiscale Structure of Starches Grafted with Hydrophobic Groups: A New Analytical Strategy. Molecules 2020, 25, 2827. [Google Scholar] [CrossRef]

- Wang, R.; Li, M.; Liu, J.; Wang, F.; Wang, J.; Zhou, Z. Dual Modification Manipulates Rice Starch Characteristics Following Debranching and Propionate Esterification. Food Hydrocoll. 2021, 119, 106833. [Google Scholar] [CrossRef]

- Gutiérrez, T.J. Effects of Exposure to Pulsed Light on Molecular Aspects of Edible Films Made from Cassava and Taro Starch. Innov. Food Sci. Emerg. Technol. 2017, 41, 387–396. [Google Scholar] [CrossRef]

- Cui, J.; Zheng, B.; Liu, Y.; Chen, L.; Li, B.; Li, L. Insights into the Effect of Structural Alternations on the Digestibility of Rice Starch-Fatty Acid Complexes Prepared by High-Pressure Homogenization. LWT 2021, 136, 110294. [Google Scholar] [CrossRef]

- Dong, S.; Fang, G.; Luo, Z.; Gao, Q. Effect of Granule Size on the Structure and Digestibility of Jackfruit Seed Starch. Food Hydrocoll. 2021, 120, 106964. [Google Scholar] [CrossRef]

- Chan, C.-H.; Wu, R.-G.; Shao, Y.-Y. The Effects of Ultrasonic Treatment on Physicochemical Properties and In Vitro Digestibility of Semigelatinized High Amylose Maize Starch. Food Hydrocoll. 2021, 119, 106831. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Bello-Pérez, L.A. Self-Assembled and Assembled Starch V-Type Complexes for the Development of Functional Foodstuffs: A Review. Food Hydrocoll. 2022, 125, 107453. [Google Scholar] [CrossRef]

- Yan, H.; Lu, Q.; Gui, J. Characteristics of A/B-Type Starch-Wheat Germ Oil Complexes and Their Effects on Noodle Texture. LWT 2021, 144, 111251. [Google Scholar] [CrossRef]

- Rodriguez-Garcia, M.E.; Hernandez-Landaverde, M.A.; Delgado, J.M.; Ramirez-Gutierrez, C.F.; Ramirez-Cardona, M.; Millan-Malo, B.M.; Londoño-Restrepo, S.M. Crystalline Structures of the Main Components of Starch. Curr. Opin. Food Sci. 2021, 37, 107–111. [Google Scholar] [CrossRef]

- Hebeish, A.; El-Rafie, M.H.; Rabie, A.M.; El-Sheikh, M.A.; El-Naggar, M.E. Ultra-Microstructural Features of Perborate Oxidized Starch. J. Appl. Polym. Sci. 2014, 131, 40170. [Google Scholar] [CrossRef]

- Lopez-Rubio, A.; Clarke, J.M.; Ben Scherer; Topping, D.L.; Gilbert, E.P. Structural Modifications of Granular Starch upon Acylation with Short-Chain Fatty Acids. Food Hydrocoll. 2009, 23, 1940–1946. [Google Scholar] [CrossRef]

- Khurshida, S.; Das, M.J.; Deka, S.C.; Sit, N. Effect of Dual Modification Sequence on Physicochemical, Pasting, Rheological and Digestibility Properties of Cassava Starch Modified by Acetic Acid and Ultrasound. Int. J. Biol. Macromol. 2021, 188, 649–656. [Google Scholar] [CrossRef]

- Goñi, I.; García-Diz, L.; Mañas, E.; Saura-Calixto, F. Analysis of Resistant Starch: A Method for Foods and Food Products. Food Chem. 1996, 56, 445–449. [Google Scholar] [CrossRef] [Green Version]

- Xie, Z.; Ding, L.; Huang, Q.; Fu, X.; Liu, F.; Dhital, S.; Zhang, B. In Vitro Colonic Fermentation Profiles and Microbial Responses of Propionylated High-Amylose Maize Starch by Individual Bacteroides-Dominated Enterotype Inocula. Food Res. Int. 2021, 144, 110317. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; Wang, S.; Wang, Z.; Fu, X.; Huang, Q.; Yuan, Y.; Wang, K.; Zhang, B. In Vitro Fecal Fermentation of Propionylated High-Amylose Maize Starch and Its Impact on Gut Microbiota. Carbohydr. Polym. 2019, 223, 115069. [Google Scholar] [CrossRef] [PubMed]

| Pasta Systems | Short-Range Ordered Structures A1045/A1011 | Hydrated Starch Structures A996/A1011 |

|---|---|---|

| NSt | 0.61 ± 0.01 b | 1.05 ± 0.01 a,b |

| NSt + Bu | 0.66 ± 0.01 c | 1.05 ± 0.01 a,b |

| NSt + Bu + TAc | 0.58 ± 0.01 a | 1.09 ± 0.01 c |

| OSt | 0.73 ± 0.01 d | 1.04 ± 0.01 a |

| OSt + Bu | 0.64 ± 0.01 c | 1.06 ± 0.01 a,b |

| OSt + Bu + TAc | 0.66 ± 0.01 c | 1.02 ± 0.01 a |

| Samples | RDS (%) | SDS (%) | TDS (%) | RS (%) |

|---|---|---|---|---|

| Cooked native corn starch * | 96 ± 3 | 11 ± 3 | 102 ± 2 | 0.8 ± 0.1 |

| NSt | 87 ± 5 a | 19 ± 1 e | 98.4 ± 0.2 b | 3.3 ± 0.3 a,b |

| NSt + Bu | 96 ± 1 c | 0.7 ± 0.1 a | 99 ± 4 b | 3.9 ± 0.8 a,b |

| NSt + Bu + TAc | 95 ± 2 c | 1.5 ± 0.6 b | 102 ± 3 b,c | 3 ± 2 a |

| OSt | 97 ± 2 c | 4.6 ± 0.2 c | 102.5 ± 0.7 b,c | 1.6 ± 0.1 a |

| OSt + Bu | 85 ± 4 a | 5.7 ± 0.2 d | 93 ± 1 a | 4 ± 1 a,b |

| OSt + Bu + TAc | 93.6 ± 0.9 b | 4 ± 1 c | 92.6 ± 0.6 a | 8 ± 2 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernandez-Hernandez, O.; Julio-Gonzalez, L.C.; Doyagüez, E.G.; Gutiérrez, T.J. Potentially Health-Promoting Spaghetti-Type Pastas Based on Doubly Modified Corn Starch: Starch Oxidation via Wet Chemistry Followed by Organocatalytic Butyrylation Using Reactive Extrusion. Polymers 2023, 15, 1704. https://doi.org/10.3390/polym15071704

Hernandez-Hernandez O, Julio-Gonzalez LC, Doyagüez EG, Gutiérrez TJ. Potentially Health-Promoting Spaghetti-Type Pastas Based on Doubly Modified Corn Starch: Starch Oxidation via Wet Chemistry Followed by Organocatalytic Butyrylation Using Reactive Extrusion. Polymers. 2023; 15(7):1704. https://doi.org/10.3390/polym15071704

Chicago/Turabian StyleHernandez-Hernandez, Oswaldo, Lesbia Cristina Julio-Gonzalez, Elisa G. Doyagüez, and Tomy J. Gutiérrez. 2023. "Potentially Health-Promoting Spaghetti-Type Pastas Based on Doubly Modified Corn Starch: Starch Oxidation via Wet Chemistry Followed by Organocatalytic Butyrylation Using Reactive Extrusion" Polymers 15, no. 7: 1704. https://doi.org/10.3390/polym15071704