Optimised Sunflower Oil Content for Encapsulation by Vibrating Technology as a Rejuvenating Solution for Asphalt Self-Healing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Blending Process of the PAV Bitumen with VCO

2.3. Chemical Characterisation of the Bitumen Samples

2.4. Physical Characterisation of the Bitumen Samples

2.5. Rheological Characterisation of the Bitumen Samples

2.6. Synthesis and Characterisation of the VCO Capsules and Their Components

- (1)

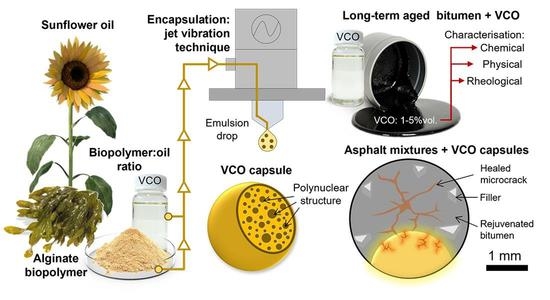

- The first step consisted of the synthesis of oil-in-water (O/W) emulsions. For this, a 2% wt. sodium alginate solution was prepared by using a magnetic stirrer (SCI550-S, Model OS40-Pro-LB Pro, Rocky Hill, CO, USA) at 250 rpm for 24 h. After this, the alginate solution was mechanically agitated at 1200 rpm for 40 min while the VCO was incorporated dropwise at three biopolymer:oil mass (B:O) ratios; 1:1, 1:5, and 1:9, resulting in three O/W emulsions with nominal viscosities @20 °C of 200.4 mPa·s, 241.50 mPa·s, and 315.5 mPa·s, respectively. The physical stability of the emulsion was evaluated by the creaming index. For this, a volume of 30 mL of each emulsion was poured into a glass vial and maintained in response for a period of 30 h. During this time, the degree of separation of the continuous (alginate solution) and disperse (VCO droplets) phases of the emulsion was measured at 0 h, 1 h, 2 h, 3 h, 6 h, 12 h, 24 h, 26 h, 28 h, and 30 h. At each time, it was determined the creaming index for all the emulsions according to the method described in Concha et al. [19] and Norambuena-Contreras et al. [18]. At each of the previous times, the size of the VCO droplets in the O/W emulsion were measured by fluorescence microscopy images (ICOE IV 5100FL, Ningbo, China) processed in the ImageJ® software (Fiji distribution, version 1.52p, National Institutes of Health, Bethesda, MD, USA).

- (2)

- A second step consisted of the encapsulation of each of the O/W emulsions by means of the vibrating jet technique using a Buchi encapsulator (B-390, Flawil, Switzerland). For this, each emulsion was pumped by applying 450–550 mbar of air pressure through a nozzle of 750 µm coupled to a vibrating unit settled to 350 Hz. With these settings, the outgoing O/W emulsion with a laminar flow from the nozzle was: (i) broken up by vibration, (ii) separated into droplets, and (iii) collected in a 5% wt. CaCl2∙2H2O hardening solution agitated at 250 rpm using a magnetic stirrer (see Figure 3). To prevent the droplets from hitting each other in flight, an electro-static charge of 1500 V was applied on the surface of the outgoing emulsion droplets from the nozzle. The freshly prepared capsules were filtered from the hardening solution and rinsed with 250 mL of deionised water later dried in an oven at 30 °C for 24 h. This resulted in the synthesis of three VCO capsule designs varying their B:O ratios, identified as 1:1, 1:5, and 1:9. Finally, the VCO capsules were stored in a freezer at -10 °C, preventing the VCO from excessive oxidation.

2.7. Manufacture and Characterisation of Asphalt Mixtures Incorporating Capsules

3. Results and Discussion

3.1. Chemical Properties of the Bitumen Blends with and without VCO

3.2. Effect of the Oil Content on the Physical Properties of a PAV-Aged Bitumen

3.3. Effect of the Oil Content on the Rheological Properties of a PAV-Aged Bitumen

3.4. Effect of the Oil Content on the Physical Stability of the Capsule’s Components

3.5. Effect of the Oil Content on the Physical, Thermal, and Mechanical Performance of the Capsules

3.6. Effect of the Capsule Design on the Physical Properties of Asphalt Mixtures

4. Conclusions

- Chemical analysis by FTIR-ATR proved that adding a 4% vol. of VCO into a PAV-aged bitumen reduced its ageing indices to a level similar to the RTFO ageing state. For this VCO content, SARA analysis showed a softening effect for the PAV-aged bitumen, significantly increasing the saturates (+130.56%) and aromatics (+35.15%);

- Physical characterisation showed that a 4% vol. of VCO into a PAV-aged bitumen increased the penetration and decreased the softening point and viscosity to the RTFO condition. From these tests, an optimal minimum VCO content was stated at 3.61% vol. bitumen for the rejuvenation purpose;

- Rheological analysis evidenced a reduction in |G*| and an increase in δ with the addition of VCO into a PAV bitumen, resulting in a softer and more viscous bitumen. A VCO content of 4% vol. bitumen was the recommended dosage to recover the rheological properties of a PAV-aged bitumen to the RTFO state;

- Creaming tests revealed that increasing the B:O ratio from 1:1 to 1:9 improved the physical stability of the O/W emulsions for synthesising VCO capsule. Capsule synthesis should be conducted promptly after emulsion synthesis to prevent instability;

- Reducing the B:O ratio from 1:1 to 1:9 produced larger capsules (1.14 mm to 1.76 mm), with high encapsulation efficiencies (93.94% to 95.23%) and high VCO content per gram of capsules (0.217 g to 0.601 g). For the rejuvenation target, capsules with high B:O ratio required a higher dosage than those with low B:O ratio;

- VCO capsules with low B:O ratios presented better thermal stability but lower mechanical stability. Capsules with a B:O ratio of 1:5 presented no thermal degradation and a compression strength over the compaction of an asphalt mixture;

- Bulk density variations in the mixtures with the addition of VCO capsules depended on the morphology of the capsules, so the lower their size, the lower the air void content and the higher the bulk density of the asphalt mixture.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anupam, B.R.; Sahoo, C.; Chandrappa, A.K. A Methodological Review on Self-Healing Asphalt Pavements. Constr. Build. Mater. 2022, 321, 126395. [Google Scholar] [CrossRef]

- Gonzalez-Torre, I.; Norambuena-Contreras, J. Recent Advances on Self-Healing of Bituminous Materials by the Action of Encapsulated Rejuvenators. Constr. Build. Mater. 2020, 258, 119568. [Google Scholar] [CrossRef]

- Wang, X.; Guo, G.; Zou, F.; Zhao, H.; Li, Y. Enhancing Self-Healing Properties of Microcrack on Aged Asphalt Incorporating with Microcapsules Encapsulating Rejuvenator. Constr. Build. Mater. 2022, 344, 128123. [Google Scholar] [CrossRef]

- Li, J.; Ji, X.-P.; Fang, X.-Z.; Hu, Y.-L.; Hua, W.-L.; Zhang, Z.-M.; Shao, D.-Y. Self-Healing Performance and Prediction Model of Microcapsule Asphalt. Constr. Build. Mater. 2022, 330, 127085. [Google Scholar] [CrossRef]

- Yuechao, Z.; Meizhu, C.; Shaopeng, W.; Qi, J. Rheological Properties and Microscopic Characteristics of Rejuvenated Asphalt Using Different Components from Waste Cooking Oil. J. Clean. Prod. 2022, 370, 133556. [Google Scholar] [CrossRef]

- Li, F.; Wang, Y.; Miljković, M.; Chan, K.M. Changes in the Nanoscale Asphaltene Particles and Relaxation Spectra of Asphalt Binders during Aging and Rejuvenation. Mater. Des. 2022, 219, 110808. [Google Scholar] [CrossRef]

- Behnood, A. Application of Rejuvenators to Improve the Rheological and Mechanical Properties of Asphalt Binders and Mixtures: A Review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Rajib, A.I.; Samieadel, A.; Zalghout, A.; Kaloush, K.E.; Sharma, B.K.; Fini, E.H. Do All Rejuvenators Improve Asphalt Performance? Road Mater. Pavement Des. 2020, 23, 358–376. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Lin, P.; Erkens, S.; Gao, Y. Chemical Characterizations and Molecular Dynamics Simulations on Different Rejuvenators for Aged Bitumen Recycling. Fuel 2022, 324, 124550. [Google Scholar] [CrossRef]

- Eltwati, A.; Mohamed, A.; Hainin, M.R.; Jusli, E.; Enieb, M. Rejuvenation of Aged Asphalt Binders by Waste Engine Oil and SBS Blend: Physical, Chemical, and Rheological Properties of Binders and Mechanical Evaluations of Mixtures. Constr. Build. Mater. 2022, 346, 128441. [Google Scholar] [CrossRef]

- Jing, R.; Varveri, A.; Liu, X.; Scarpas, A.; Erkens, S. Ageing Effect on Chemo-Mechanics of Bitumen. Road Mater. Pavement Des. 2021, 22, 1044–1059. [Google Scholar] [CrossRef] [Green Version]

- Porto, M.; Angelico, R.; Caputo, P.; Abe, A.A.; Teltayev, B.; Rossi, C.O. The Structure of Bitumen: Conceptual Models and Experimental Evidences. Materials 2022, 15, 905. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Du, R.; Gong, L.; Wang, H.; Wang, K. Determination of Asphalt Aging Degree: A Novel Method to Determine Asphaltene Content by Centrifugal Separation and Air Stripping Technologies. Pet. Sci. Technol. 2022, 40, 1190–1196. [Google Scholar] [CrossRef]

- Loise, V.; Calandra, P.; Abe, A.A.; Porto, M.; Oliviero Rossi, C.; Davoli, M.; Caputo, P. Additives on Aged Bitumens: What Probe to Distinguish between Rejuvenating and Fluxing Effects? J. Mol. Liq. 2021, 339, 116742. [Google Scholar] [CrossRef]

- Rathore, M.; Haritonovs, V.; Merijs Meri, R.; Zaumanis, M. Rheological and Chemical Evaluation of Aging in 100% Reclaimed Asphalt Mixtures Containing Rejuvenators. Constr. Build. Mater. 2022, 318, 126026. [Google Scholar] [CrossRef]

- Yan, K.; Lan, H.; Duan, Z.; Liu, W.; You, L.; Wu, S.; Miljković, M. Mechanical Performance of Asphalt Rejuvenated with Various Vegetable Oils. Constr. Build. Mater. 2021, 293, 123485. [Google Scholar] [CrossRef]

- Yan, S.; Dong, Q.; Chen, X.; Zhou, C.; Dong, S.; Gu, X. Application of Waste Oil in Asphalt Rejuvenation and Modification: A Comprehensive Review. Constr. Build. Mater. 2022, 340, 127784. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Concha, J.L.; Arteaga-Pérez, L.E.; Gonzalez-Torre, I. Synthesis and Characterisation of Alginate-Based Capsules Containing Waste Cooking Oil for Asphalt Self-Healing. Appl. Sci. 2022, 12, 2739. [Google Scholar] [CrossRef]

- Concha, J.L.; Arteaga-Pérez, L.E.; Alpizar-Reyes, E.; Segura, C.; Gonzalez-Torre, I.; Kanellopoulos, A.; Norambuena-Contreras, J. Effect of Rejuvenating Oil Type on the Synthesis and Properties of Alginate-Based Polynuclear Capsules for Asphalt Self-Healing. Road Mater. Pavement Des. 2022, 1–26. [Google Scholar] [CrossRef]

- Ruiz-Riancho, N.; Saadoon, T.; Garcia, A.; Grossegger, D.; Hudson-Griffiths, R. Optimisation of Self-Healing Properties for Asphalts Containing Encapsulated Oil to Mitigate Reflective Cracking and Maximize Skid and Rutting Resistance. Constr. Build. Mater. 2021, 300, 123879. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Q.; Wu, J.; Wan, P.; Zhao, F. Self-Healing Performance of Asphalt Concrete with Ca-Alginate Capsules under Low Service Temperature Conditions. Polymers 2022, 15, 199. [Google Scholar] [CrossRef] [PubMed]

- Concha, J.L.; Arteaga-Pérez, L.E.; Gonzalez-Torre, I.; Liu, Q.; Norambuena-Contreras, J. Biopolymeric Capsules Containing Different Oils as Rejuvenating Agents for Asphalt Self-Healing: A Novel Multivariate Approach. Polymers 2022, 14, 5418. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Riancho, N.; Garcia, A.; Grossegger, D.; Saadoon, T.; Hudson-Griffiths, R. Properties of Ca-Alginate Capsules to Maximise Asphalt Self-Healing Properties. Constr. Build. Mater. 2021, 284, 122728. [Google Scholar] [CrossRef]

- Zhang, L.; Hoff, I.; Zhang, X.; Yang, C. Investigation of the Self-Healing and Rejuvenating Properties of Aged Asphalt Mixture Containing Multi-Cavity Ca-Alginate Capsules. Constr. Build. Mater. 2022, 361, 129685. [Google Scholar] [CrossRef]

- Martins, E.; Poncelet, D.; Rodrigues, R.C.; Renard, D. Oil Encapsulation Techniques Using Alginate as Encapsulating Agent: Applications and Drawbacks. J. Microencapsul. 2017, 34, 754–771. [Google Scholar] [CrossRef]

- Wan, P.; Wu, S.; Liu, Q.; Zou, Y.; Zhao, Z.; Chen, S. Recent Advances in Calcium Alginate Hydrogels Encapsulating Rejuvenator for Asphalt Self-Healing. J. Road Eng. 2022, 2, 181–220. [Google Scholar] [CrossRef]

- NCAT. NCAT Researchers Explore Multiple Uses of Rejuvenators. Asph. Technol. News 2014, 26, 7–8. [Google Scholar]

- De Bock, L.; Piérard, N.; Vansteenkiste, S.; Vanelstraete, A. Dossier 21. Categorisation and Analysis of Rejuvenators for Asphalt Recycling; Belgian Road Research Centre: Brusels, Belgium, 2020. [Google Scholar]

- Shirzad, S.; Hassan, M.M.; Aguirre, M.A.; Mohammad, L.N.; Daly, W.H. Evaluation of Sunflower Oil as a Rejuvenator and Its Microencapsulation as a Healing Agent. J. Mater. Civ. Eng. 2016, 28, 04016116. [Google Scholar] [CrossRef]

- Tarar, M.A.; Khan, A.H.; Ur Rehman, Z.; Qamar, S.; Akhtar, M.N. Compatibility of Sunflower Oil with Asphalt Binders: A Way toward Materials Derived from Renewable Resources. Mater. Struct./Mater. Constr. 2020, 53, 64. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Liu, Q.; Zhang, L.; Wu, S.; Yalcin, E.; Garcia, A. Influence of Encapsulated Sunflower Oil on the Mechanical and Self-Healing Properties of Dense-Graded Asphalt Mixtures. Mater. Struct./Mater. Constr. 2019, 52, 78. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Peng, Z.; Wu, J.; Liu, Q.; Zhao, F.; Wan, P. A Comparative Study on the Release Behavior of Self-Healing Capsules under Different Asphalt Mixing and Transportation Conditions. Constr. Build. Mater. 2022, 348, 1–13. [Google Scholar] [CrossRef]

- Xu, S.; Liu, X.; Tabaković, A.; Lin, P.; Zhang, Y.; Nahar, S.; Lommerts, B.J.; Schlangen, E. The Role of Rejuvenators in Embedded Damage Healing for Asphalt Pavement. Mater. Des. 2021, 202, 109564. [Google Scholar] [CrossRef]

- ASTM D 2872-19; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM D 6521-19; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Hofko, B.; Zia Alavi, M.; Grothe, H.; Jones, D.; Harvey, J. Repeatability and Sensitivity of FTIR ATR Spectral Analysis Methods for Bituminous Binders. Mater. Struct. 2017, 50, 187. [Google Scholar] [CrossRef] [Green Version]

- ASTM D 4124-09; Standard Test Method for Separation of Asphalt into Four Fractions. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- ASTM D 5-97; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 1997. [CrossRef]

- ASTM D 36-06; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2006. [CrossRef]

- ASTM D 4402-06; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2006. [CrossRef]

- ASTM D 7175-15; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- Papagiannakis, A.T.; Masad, E.A. Pavement Design and Materials; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Alpizar-Reyes, E.; Concha, J.L.; Martín-Martínez, F.J.; Norambuena-Contreras, J. Biobased Spore Microcapsules for Asphalt Self-Healing. ACS Appl. Mater. Interfaces 2022, 14, 31296–31311. [Google Scholar] [CrossRef]

- ASTM D 2726-00; Standard Test Method for Bulk Specific Gravity and Density of Non-Absorptive Compacted Bituminous Mixtures. ASTM International: West Conshohocken, PA, USA, 2000. [CrossRef]

- ASTM D 23203-05; Standard Test Method for Percent Air Voids in Compacted Dense and Open Bituminous Paving Mixtures. ASTM International: West Conshohocken, PA, USA, 2005. [CrossRef]

- Li, M.; Ren, S.; Liu, X.; Wu, Z.; Zhang, H.; Fan, W.; Lin, P.; Xu, J. A Comprehensive Study on the Rejuvenation Efficiency of Compound Rejuvenators for the Characterization of the Bituminous Binder, Mortar, and Mixture. Materials 2022, 15, 5458. [Google Scholar] [CrossRef]

- Xu, S.; Tabaković, A.; Liu, X.; Palin, D.; Schlangen, E. Optimization of the Calcium Alginate Capsules for Self-Healing Asphalt. Appl. Sci. 2019, 9, 468. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.J.; Liu, Y.; Cui, L.; Yan, C.; Zhu, P. Bio-Based Calcium Alginate Nonwoven Fabrics: Flame Retardant and Thermal Degradation Properties. J. Anal. Appl. Pyrolysis 2016, 122, 13–23. [Google Scholar] [CrossRef]

- Gouveia de Souza, A.; Oliveira Santos, J.C.; Conceição, M.M.; Dantas Silva, M.C.; Prasad, S. A Thermoanalytic And Kinetic Study Of Sunflower Oil. Braz. J. Chem. Eng. 2004, 21, 265–273. [Google Scholar] [CrossRef] [Green Version]

- Delgadillo, R.; Bahia, H.U. Effects of Temperature and Pressure on Hot Mixed Asphalt Compaction: Field and Laboratory Study. J. Mater. Civ. Eng. 2008, 20, 440–448. [Google Scholar] [CrossRef]

| Sieve Size (mm) | % Passing |

|---|---|

| 19 | 100 |

| 12.5 | 84 |

| 10 | 72 |

| 4.75 | 50 |

| 2.36 | 35 |

| 0.6 | 16 |

| 0.3 | 11 |

| 0.15 | 7 |

| 0.075 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Concha, J.L.; Delgadillo, R.; Arteaga-Pérez, L.E.; Segura, C.; Norambuena-Contreras, J. Optimised Sunflower Oil Content for Encapsulation by Vibrating Technology as a Rejuvenating Solution for Asphalt Self-Healing. Polymers 2023, 15, 1578. https://doi.org/10.3390/polym15061578

Concha JL, Delgadillo R, Arteaga-Pérez LE, Segura C, Norambuena-Contreras J. Optimised Sunflower Oil Content for Encapsulation by Vibrating Technology as a Rejuvenating Solution for Asphalt Self-Healing. Polymers. 2023; 15(6):1578. https://doi.org/10.3390/polym15061578

Chicago/Turabian StyleConcha, Jose L., Rodrigo Delgadillo, Luis E. Arteaga-Pérez, Cristina Segura, and Jose Norambuena-Contreras. 2023. "Optimised Sunflower Oil Content for Encapsulation by Vibrating Technology as a Rejuvenating Solution for Asphalt Self-Healing" Polymers 15, no. 6: 1578. https://doi.org/10.3390/polym15061578