1. Introduction

Modern technological advancements in weaponry and ammunition, as well as wearer requirements for comfort and mobility, have led to the development of new body armor materials that are flexible and light weight, with increased damage resistance and better energy absorption capacity [

1]. Many light-weight ballistic protective armor systems are currently constructed using high modulus and high strength polymeric fibers such as ultra-high-molar-mass polyethylene (UHMMPE) [

2,

3] and poly(p-phenylene terephthalamide), or PPTA [

4,

5], commonly known as aramid, and new composites are also quickly emerging [

6]. In order to ensure the wearer’s safety over the armor’s expected use lifetime, the development of these new materials and their use in body armor applications requires a deep understanding of their long-term stability and potential degradation mechanisms. Historically, little emphasis was placed on the long-term performance of armor materials. However, there was a renewed effort to understand the body armor failure mechanisms in the wake of an armor failure in 2003 [

7]. Significant efforts have been launched to examine the mechanisms of aging in UHMMPE and PPTA fibers.

There are several advantages to flexible UD composite laminates compared to traditional woven material. Flexible UD laminates have been shown to absorb more energy per unit panel weight [

8,

9,

10], with similar applications and flexibility as woven fabrics [

11]. In addition, UD composite laminates with UHMMPE or PPTA fibers have been shown to perform significantly better in out-of-plane compression compared to woven materials [

12]. Either UHMMPE or PPTA fibers can be used in combination with an elastic resin material (20% or less by mass) [

13] that can penetrate to the filament level and hold the fibers together to form a non-woven unidirectional (UD) tape. Layers of the unidirectional tape are laminated together in a crisscross pattern, where each layer is placed at a 90° angle from the layer above and below to form a panel, as depicted in

Figure 1, where there are four such UD layers. Unidirectional fiber composite materials can vary significantly based on their intended application. Composites developed for aerospace applications can be hundreds of fibers thick with a high matrix volume fraction up to 50% [

14], whereas in body armor applications, each layer has a thickness of less than 10 fibers (as can be seen in

Figure 1) with lower matrix volume fractions due to the near-hexagonal packing arrangement of the fibers [

9].

The degradation of UHMMPE fibers and the subsequent decrease in their mechanical properties under normal use conditions, involving elevated temperature, humidity, or some combination thereof, can occur through a well-documented process known as thermal oxidation [

2,

15,

16,

17,

18,

19,

20,

21,

22,

23]. Elevated temperatures can induce C–C bond scissions along the backbone of a UHMMPE chain, primarily in the amorphous regions of the polymer [

24]. The rupture of these bonds results in the formation of C-centered free radicals (alkyl radicals) that can undergo various reactions which, in general, depend on the presence of oxygen in the amorphous areas, the concentration of oxygen present, the temperature, the moisture content, the presence of antioxidants in the material, and the degree of crystallinity [

3,

24,

25,

26]. In the presence of oxygen solubilized in the amorphous regions of UHMMPE, alkyl free radicals will be involved in a series of reactions that can further decrease the molar mass of the polymer and result in products such as ketones, alcohols, and water, as shown in

Figure 2 [

3,

24,

27,

28]. These products will give the polymer hydrophilic properties, to a certain extent, making it more susceptible to moisture, which can, in turn, penetrate the polymer and induce more oxidation over time.

Compared to the UHMMPE yarns, only preliminary research has been performed to characterize the effect of environmental exposure on the matrix used in the UD laminates. Furthermore, the effect of changes in the binders on the ballistic performance of the UD laminate is unclear as the impact force is carried mainly by the fibers. A computational study investigating the ballistic performance of UHMMPE UD laminate composites, however, has shown that filament/matrix de-bonding/cohesion is of paramount importance in the performance of these materials and one of the main failure parameters upon impact [

29]. Hence, it is prudent to test the entire composite structure to comprehensively determine the effects of aging. The current study evaluates the tensile strength of a UHMMPE flexible UD laminate under two sets of environmental aging conditions. Of key interest is how the

V50 velocity, the velocity at which half of the projectiles penetrate, changes with aging. The

V50 can be related to the tensile strength through empirical research by Cunniff [

30] and theoretical research by Phoenix and Porwal [

31], as detailed in [

5,

32]. Furthermore, tensile strength was chosen as a relevant metric because it is less complicated to measure than

V50 and requires less material.

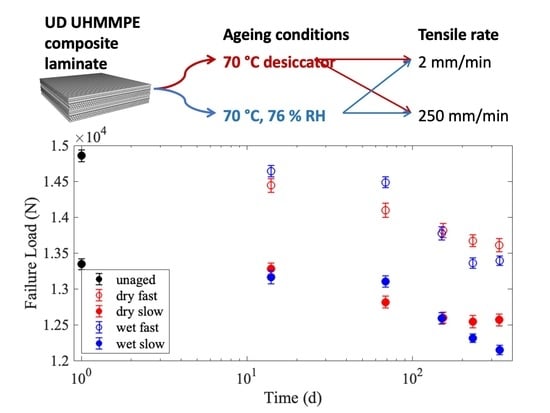

3. Results

All data associated with this publication is archived through the NIST Public Data Repository [

34]. Specimens of the UD material were cut 70 mm wide, aged at two different humidity levels for the periods previously described, and tested at two different crosshead displacement rates.

Figure 5 is a plot of the average failure load, also referred to as the strength, with at least 50 specimens per testing condition. Specimens tested at the faster loading rate of 250 mm/min are plotted with open markers, while specimens tested at the slower loading rate of 2 mm/min have filled markers. The color red and term ‘dry’ is used to indicate that the specimens were aged at 70 °C in a desiccator, while the blue color and term ‘wet’ indicates aging at 70 °C and 76% relative humidity. The error bars in

Figure 5 are the standard deviation of the mean failure load retention divided by the square root of the number of specimens. The failure load decreased after exposure to elevated temperatures, as seen in

Figure 5. This is indicative of degradation, although the percent degradation is less than 10% (9.9% for wet fast, 9.0% for wet slow, 8.4% for dry fast, and 5.8% for dry slow), indicating that the material retains most of its failure load after exposure to these aging conditions.

The specimens tested at lower loading rates are much weaker than those tested at faster loading rates. This rate dependence has been seen for other similar composites [

5] and is to be expected. Phoenix and Newman developed models for fiber and composite rate dependence and time-dependent properties [

36,

37]. When the matrix is significantly more complaint than the fibers, as is the case in these UHMMPE laminates, the rate dependence of the composite laminate is predominantly driven by the binder matrix properties compared to the fibers. When the loading rate is sufficiently slow, the matrix has time to creep in shear. Creep in the matrix increases the overloaded length near to a broken fiber(s). Thus, matrix creep properties play a defining role in the composite’s failure load at slow loading rates. In contrast, at fast loading rates, there is no time for the matrix to creep, so only the initial elastic overload length is relevant. This is described, in detail, by Engelbrecht-Wiggans [

38,

39].

The degradation in failure load, while less than 10%, is statistically significant.

Figure 6 shows that with aging, the failure distributions shift to smaller failure loads, indicative of degradation while maintaining the same slope. The constant slope is notable because it implies that the mechanism for failure has not changed.

Figure 6 is plotted as a normal probability plot because the failure distributions for these specimens are well described by a normal distribution, as opposed to a Weibull distribution. Comparable testing performed on PPTA laminates of a similar construction resulted in Weibull-distributed failure load distributions [

5]. As the laminate construction is highly similar, it is reasonable to conclude that the different fiber and matrix give rise to the different failure load distributions. UHMMPE fibers are well known to have a low frictional force, and the bond strength between fibers and the matrix is typically much lower than that for PPTA fibers. This gives rise to a much longer load transfer length around a broken fiber in UHMMPE than in PPTA. The Weibull distribution arises from concentrated, local damage, which relies on a shorter load transfer length [

38,

39,

40]. Comparison of the failure videos of the UHMMPE specimens [

34] and the PPTA specimens [

41] show that the PPTA failures are highly localized, while the UHMMPE ones are not. For the PPTA, the material 5 cm away from the failure site visually appears untested, while for the UHMMPE laminate, there are loose fibers throughout the gauge length, and there are typically several breaks along the length of the specimen. This corroborates that, while the PPTA material failed according to local load sharing, giving rise to a Weibull failure load distribution, the UHMMPE material behaves more according to global load sharing, giving rise to a normal distribution [

40]. Hence the failure distributions will be plotted as normal distributions for the purposes of this work.

As mentioned in the Experimental Section, the laminate had visible damage.

Figure 7 shows the failure distributions for the unaged and most aged conditions, broken down by the amount of visible damage that was assessed prior to aging. While the specimens were initially placed into five different damage categories, these were grouped together for three different classifications for clarity of display on the figure. In general, for the aging conditions shown in

Figure 7 as well as the ones not pictured, there are no significant differences between the failure distributions at the different damage levels. Of all the aging conditions, the dry 335 d specimens show some of the largest differences. However, even after 335 d of aging, the curves overlap, showing that the failure load of the most damaged specimens is greater than that of the only minorly damaged specimens. A lack of correlation between visible damage and failure load is consistent with prior observations [

2]. It may be that the only fibers that break due to the visible damage are the weak fibers that would break during loading anyway, thus explaining the invariance of the failure load to damage level.

In addition to the failure load decreasing with aging, the modulus also decreases, as can be seen in

Figure 8, where the load vs. strain curves for the unaged material are plotted in black, and the aged curves are plotted in red/pink for the specimens aged in a desiccator and blue for the specimens aged at 76% RH. For the specimens subjected to a slow loading rate, there is a clear separation between aged and unaged curves at higher strains (see

Figure 8). This decrease in modulus is less pronounced at the faster loading rate, where there is less time for slip and creep to occur. It is not clear how much of a change in modulus would be seen at ballistic rates.

Standard definitions of modulus require calculating the slope of the stress strain curve in the elastic region. The definition of the elastic region is not immediately clear from these load vs. strain curves as there is no well-defined point where the curve deviates from linearity. To investigate this, cyclic loading tests were performed on unaged and aged material. The results for the unaged material are presented in

Figure 9, while

Figure 10 is for the aged material. Furthermore,

Figure 9 compares the load vs. strain and the load vs. displacement plots for an unaged sample. The video extensometer is limited to capturing 17 frames per second, which adds artefacts to the curve at the locations where the crosshead switches direction. Due to this,

Figure 8 and

Figure 9 are of load vs. displacement. A load vs. strain version of

Figure 9 is presented in the

Appendix A.

In

Figure 7 and

Figure 8, the leftmost column is a plot of the entire test as recorded by the data collection software. The other two columns are of the loading and unloading portions of this curve, with all of the loading portions in the middle column and the unloading in the right column. These loading and unloading curves were shifted to all start at zero displacement to allow for a comparison of how the shape changes as loading progresses. For comparison,

Figure 11 plots the final loading and unloading portion of the curves on the same axes for all three materials, again shifted to start at zero displacement.

Elastic deformation is typically defined as deformation that is entirely reversible when the load is removed. The first ten cycles of 50 N to 500 N are completely reversible, almost perfectly superimposing in

Figure 9. The first few cycles show some differences, particularly in the load vs displacement plot (as opposed to the strain version) as the specimen tightens on the grips. By the ninth and tenth cycles, however, the overlap in

Figure 9 is close to perfect, indicating that the specimen has tightened onto the grips as far as it will for a maximum load of 500 N. Even in this low region (cycling between 50 and 500 N), the material is not perfectly linear, and there is a hysteresis loop. For the next two loadings (with maximum loads of 1.5 and 2.5 kN), the behavior follows the prior loading curves. As the load increases further, however, plastic deformation and viscous behavior start to play a role as each loading curve has a larger gap between it and where the previous maximum load was. Thus, plastic deformation starts occurring at fairly low loads of less than 6.5 kN, even though failure occurs at over 12 kN.

The loading curves mostly superimpose, with better superimposition as the load increases. For each loading curve, the greatest change in the local modulus (focusing on a range of 0.375 kN) increases as the load increases until the maximum load is greater than 6.5 kN. After this load is exceeded, the tangent modulus decreases. In addition, after loading to 6.5 kN, the tangent modulus values are highly similar in each subsequent loading. In contrast, the viscous behavior apparent in the unloading curves changes on each cycle as the unloading lines do not follow the same curve, though there appears to be some sort of lower envelope curve that they converge to as the load drops to zero. The difference in similarity in tangent modulus behavior across multiple loading cycles and a difference in the relaxation time can be seen in all three cyclic figures. The material demonstrates hysteresis, indicative of a viscoelastic or viscoplastic material, and aging results in a more pronounced change to the relaxation and unloading behavior than the loading behavior, as seen in

Figure 11, with both aged specimens having a shallower lower unloading curve that steepens and crosses the unaged curve at higher loads. The relevance of the change in relaxation times to ballistic applications (for which this material is intended) is unclear; however, it is clear that the material’s behavior is changing over time in complex ways.

In addition to changes in the failure load and modulus, the failure strain also changes with aging, as can be seen in

Figure 12. However, the changes for the failure strain are more complex. The failure strain initially increases with aging at all loading rates and aging conditions, but as aging continued, there became no clear trend for the failure strain. For the fast loading rate, the aged failure strain distribution is sometimes greater than and sometimes less than the unaged distribution, while for the slow loading rate, the strain for the aged material is typically greater than that for the unaged. Some of this variability may be due to measurement error, or it could be that initially the degradation due to aging causes an increased failure strain as only a few fibers are broken; hence, there is simply more slip before failure. At higher levels of aging, there is more damage, so the failure happens sooner, causing either only a modest increase in failure strain or no increase at all.

Throughout this analysis, there have only been minor differences observed in failure load between the specimens aged in the humid and dry environments. This is despite an obvious visual difference in these specimens after aging, with the specimens that were aged in the humid environment turning brown. This implies that the visible signs of aging are occurring in the matrix rather than the fibers themselves. Any differences in the matrix degradation should show up more clearly in the specimens tested at the lower loading rate.

Figure 5 shows that the specimens tested at the slower loading rate are seen to have a larger decrease in failure load than the specimens tested at faster loading rates, and the specimens aged at humid conditions for long aging times show a larger decrease in failure load than their dry counterparts, perhaps due to an increased load transfer length in the matrix because of matrix degradation.

At most, the degradation in failure load for any of the specimens is less than 10% of the initial failure load and was observed mostly in the specimens tested at slower loading rates. The prior work [

2] shows that the failure load of UHMMPE yarns was more significantly reduced by aging at temperatures similar to those used in this study. At approximately 8000 hr (333 d) of aging at 65 °C, a failure load reduction of 25% was observed, more than twice the amount measured in the current study. This difference could be explained by the fact that the polyethylene in the two studies was from different manufacturers. Thus, the formulations may be slightly different, such as the selection and concentration of antioxidants, which could impact their susceptibility to oxidation. In addition, bare yarns were exposed in the prior study, and in this study, the yarns were encased in a matrix, which may reduce opportunities for oxygen diffusion into the material, thus slowing oxidation.

Although broadly a decrease in failure load was observed as a function of aging time, there is scatter in the trend, which is expected when sampling from a distribution. Between 50 and 57 specimens were tested in each set to provide relatively high confidence intervals on the mean. While a distribution of failure loads is expected from basic Normal/Weibull principles, there are other considerations that may further complicate comparisons. In particular, the failure load may exhibit spatial variation within the roll. This could be due to damage caused during manufacture or transportation and handling, typically to the edges of the roll or the outermost layers. Certain manufacturing defects also create location-dependent strength if a warp thread is consistently damaged during the lamination process, for instance. The specimens were randomly assigned from the original roll location, controlling for visible damage, so location-dependence in failure load should not be affecting these results. Another consideration is the cutting accuracy with regard to a constant specimen width. Specimens were nominally 70 mm wide. Although variations in width between individual specimens could be as much as 1 mm, this width effect on failure load should be minimal.

The

V50 ballistic performance measure can be calculated from the tensile properties following either Cunniff [

30] or Phoenix and Porwal [

31], as described in [

32]. The predicted

V50 retention is presented in

Figure 13, where mean retention is calculated by scaling the

V50 values at various aging times by the predicted initial

V50. The error bars in

Figure 13 are the coefficient of variation (standard deviation divided by the mean), scaled by the mean initial

V50 value. The trends for predicted

V50 do not perfectly follow the failure load degradation (seen in

Figure 5) as the

V50 calculation also takes into account changes in the modulus and failure strain. The Phoenix and Porwal method is more sensitive to failure strain, which is why it fluctuates more than the Cunniff method. For all methods, aging conditions, and loading rates, the drop in predicted

V50 is never more than 11%. The largest decrease in predicted

V50 values is seen for the specimens tested at the faster loading rates, with the fast and wet specimens having a minimum

V50 retention of 0.893 and the fast and dry specimens having a minimum

V50 retention of 0.905. In contrast, the specimens tested at a slow loading rate had minimum predicted

V50 retentions of 0.957 and 0.945 for the dry and wet conditions, respectively. There is reason to believe that these predictions may be conservative, based on other research [

32], and that the true reduction in

V50 may be even less than that predicted by the Cunniff or the Phoenix–Porwal models.

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.