3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA)

Abstract

:1. Introduction

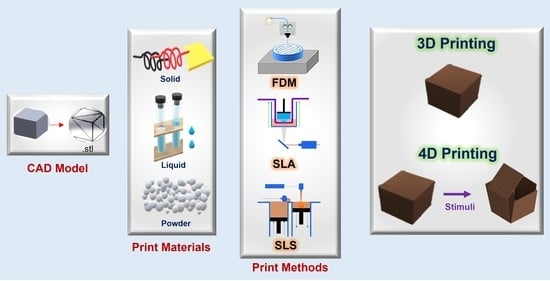

2. Printing Process

3. Print Materials

3.1. Material Requirements

3.1.1. Mechanical Properties

3.1.2. Extrinsic Properties

3.1.3. Chemical Properties

3.1.4. Thermal Properties

3.1.5. Optical Properties

3.1.6. Rheological Properties

4. Properties of Printed Parts

4.1. Tensile Properties

4.2. Flexural Properties

5. Towards Magneto-Active 4D Printing

6. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| CAD | Computer-Aided Design |

| ASTM | American Society for Testing and Materials |

| FDM | Fused Deposition Modelling |

| LOM | Laminated Object Manufacturing |

| WAAM | Wire and Arc Additive Manufacturing |

| EBF3 | Electron Beam Free Form Fabrication |

| SLS | Selective Laser Sintering |

| EBM | Electron Beam Melting |

| SLM | Selective Laser Melting |

| LMD | Laser Metal Deposition |

| SLA | Stereolithography |

| MJ | Material Jetting |

| STL | Standard Tessellation Language |

| FFF | Fused Filament Fabrication |

| PLA | Polylactic Acid |

| SLA | Selective Laser Sintering |

| PP | Polypropylene |

| TPU | Thermoplastic Polyurethane |

| TPE | Thermoplastic Elastomer |

| ABS | Acrylonitrile Butadiene Styrene |

| TGA | Thermogravimetric Analysis |

| PA | Polyamide |

| PEEK | Polyether Ether Ketone |

| TGA | Thermogravimetric Analysis |

| PCL | Polycaprolactone |

| PLGA | Polylactic Glycolic Acid |

| PEI | Polyethylenimine |

| PEKK | Polyetherketoneketone |

| ASA | Acrylonitrile Styrene Acrylate |

| PMMA | Polymethyl Methacrylate |

| PS | Polystyrene |

| PET | polyethylene Terephthalate |

| PES | Polyethersulfone |

| PVA | Polyvinyl Alcohol |

| PPF | Polypropylene Fumarate |

| PTMC | Polytrimethylene Carbonate |

| PEG | Polyethylene Glycol |

| DSC | Differential Scanning Calorimetry |

| CIPs | Carbonyl Iron Powders |

| DLP | Direct Laser Processing |

| μCLIP | Micro-Continuous Liquid Interface Production |

| DIW | Direct Ink Write |

References

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef] [PubMed]

- Khoo, Z.X.; Teoh, J.E.M.; Liu, Y.; Chua, C.K.; Yang, S.; An, J.; Leong, K.F.; Yeong, W.Y. 3D printing of smart materials: A review on recent progresses in 4D printing. Virtual Phys. Prototyp. 2015, 10, 103–122. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Zhu, C.; Li, T.; Mohideen, M.M.; Hu, P.; Gupta, R.; Ramakrishna, S.; Liu, Y. Realization of circular economy of 3D printed plastics: A review. Polymers 2021, 13, 744. [Google Scholar] [CrossRef] [PubMed]

- Tareq, M.S.; Rahman, T.; Hossain, M.; Dorrington, P. Additive manufacturing and the COVID-19 challenges: An in-depth study. J. Manuf. Syst. 2021, 60, 787–798. [Google Scholar] [CrossRef]

- Goh, G.D.; Sing, S.L.; Yeong, W.Y. A review on machine learning in 3D printing: Applications, potential, and challenges. Artif. Intell. Rev. 2021, 54, 63–94. [Google Scholar] [CrossRef]

- Pérez, M.; Carou, D.; Rubio, E.M.; Teti, R. Current advances in additive manufacturing. Procedia CIRP 2020, 88, 439–444. [Google Scholar] [CrossRef]

- Hossain, M.A.; Zhumabekova, A.; Paul, S.C.; Kim, J.R. A review of 3D printing in construction and its impact on the labor market. Sustainability 2020, 12, 8492. [Google Scholar] [CrossRef]

- 3D Concrete Printing Market to Reach $56.4 Million by 2021—3Printr.com. Available online: https://www.3printr.com/3d-concrete-printing-market-reach-56-4-million-2021-1239664/ (accessed on 31 August 2021).

- Low, Z.X.; Chua, Y.T.; Ray, B.M.; Mattia, D.; Metcalfe, I.S.; Patterson, D.A. Perspective on 3D printing of separation membranes and comparison to related unconventional fabrication techniques. J. Memb. Sci. 2017, 523, 596–613. [Google Scholar] [CrossRef] [Green Version]

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.D.M.; Domínguez, M. Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 9656938. [Google Scholar] [CrossRef] [Green Version]

- Espalin, D.; Muse, D.W.; MacDonald, E.; Wicker, R.B. 3D Printing multifunctionality: Structures with electronics. Int. J. Adv. Manuf. Technol. 2014, 72, 963–978. [Google Scholar] [CrossRef]

- Goyanes, A.; Det-Amornrat, U.; Wang, J.; Basit, A.W.; Gaisford, S. 3D scanning and 3D printing as innovative technologies for fabricating personalized topical drug delivery systems. J. Control. Release 2016, 234, 41–48. [Google Scholar] [CrossRef] [PubMed]

- Goh, G.D.; Yap, Y.L.; Tan, H.K.J.; Sing, S.L.; Goh, G.L.; Yeong, W.Y. Process–Structure–Properties in Polymer Additive Manufacturing via Material Extrusion: A Review. Crit. Rev. Solid State Mater. Sci. 2020, 45, 113–133. [Google Scholar] [CrossRef]

- Goh, G.D.; Agarwala, S.; Goh, G.L.; Dikshit, V.; Sing, S.L.; Yeong, W.Y. Additive manufacturing in unmanned aerial vehicles (UAVs): Challenges and potential. Aerosp. Sci. Technol. 2017, 63, 140–151. [Google Scholar] [CrossRef]

- Valvez, S.; Reis, P.N.B.; Susmel, L.; Berto, F. Fused Filament Fabrication-4D-Printed Shape Memory Polymers: A Review. Polymers 2021, 13, 701. [Google Scholar] [CrossRef]

- Jang, T.-S.; Jung, H.-D.; Pan, H.M.; Han, W.T.; Chen, S.; Song, J. 3D printing of hydrogel composite systems: Recent advances in technology for tissue engineering. Int. J. Bioprint. 2018, 4, 126. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Gadagi, B.; Lekurwale, R. A review on advances in 3D metal printing. Mater. Today Proc. 2021, 45, 277–283. [Google Scholar] [CrossRef]

- Chahal, V.; Taylor, R.M. A review of geometric sensitivities in laser metal 3D printing. Virtual Phys. Prototyp. 2020, 15, 227–241. [Google Scholar] [CrossRef]

- Murr, L.E. A Metallographic Review of 3D Printing/Additive Manufacturing of Metal and Alloy Products and Components. Metallogr. Microstruct. Anal. 2018, 7, 103–132. [Google Scholar] [CrossRef] [Green Version]

- Tan, L.J.; Zhu, W.; Zhou, K. Recent progress on polymer materials for additive manufacturing. Adv. Funct. Mater. 2020, 30, 2003062. [Google Scholar] [CrossRef]

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef] [PubMed]

- Shahbazi, M.; Jäger, H. Current Status in the Utilization of Biobased Polymers for 3D Printing Process: A Systematic Review of the Materials, Processes, and Challenges. ACS Appl. Bio Mater. 2021, 4, 325–369. [Google Scholar] [CrossRef]

- Larrañeta, E.; Dominguez-Robles, J.; Lamprou, D.A. Additive Manufacturing Can Assist in the Fight against COVID-19 and Other Pandemics and Impact on the Global Supply Chain. 3D Print. Addit. Manuf. 2020, 7, 100–103. [Google Scholar] [CrossRef]

- Luis, E.; Pan, H.M.; Sing, S.L.; Bastola, A.K.; Goh, G.D.; Goh, G.L.; Tan, H.K.J.; Bajpai, R.; Song, J.; Yeong, W.Y. Silicone 3D Printing: Process Optimization, Product Biocompatibility, and Reliability of Silicone Meniscus Implants. 3D Print. Addit. Manuf. 2019, 6, 319–332. [Google Scholar] [CrossRef]

- Luis, E.; Pan, H.M.; Bastola, A.K.; Bajpai, R.; Sing, S.L.; Song, J.; Yeong, W.Y. 3D printed silicone meniscus implants: Influence of the 3D printing process on properties of silicone implants. Polymers 2020, 12, 2136. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [Green Version]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of polymer composites: A short review. Mater. Des. Process. Commun. 2020, 2, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part. B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Hwa, L.C.; Rajoo, S.; Noor, A.M.; Ahmad, N.; Uday, M.B. Recent advances in 3D printing of porous ceramics: A review. Curr. Opin. Solid State Mater. Sci. 2017, 21, 323–347. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, X.; Shang, Y.; Xiong, K.; Xu, Z.; Guo, R.; Cai, S.; Zheng, C. Dense ceramics with complex shape fabricated by 3D printing: A review. J. Adv. Ceram. 2021, 10, 195–218. [Google Scholar] [CrossRef]

- Rasaki, S.A.; Xiong, D.; Xiong, S.; Su, F.; Idrees, M.; Chen, Z. Photopolymerization-based additive manufacturing of ceramics: A systematic review. J. Adv. Ceram. 2021, 10, 442–471. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E.; Tay, B.Y.; Zhao, Z.; Zhao, L.; Tian, Z.; Yang, S. Direct selective laser sintering and melting of ceramics: A review. Rapid Prototyp. J. 2017, 23, 611–623. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L. A critical review of preparation design and workability measurement of concrete material for largescale 3D printing. Front. Struct. Civ. Eng. 2018, 12, 382–400. [Google Scholar] [CrossRef]

- Shakor, P.; Nejadi, S.; Paul, G.; Malek, S. Review of emerging additive manufacturing technologies in 3d printing of cementitious materials in the construction industry. Front. Built Environ. 2019, 4, 85. [Google Scholar] [CrossRef] [Green Version]

- Mohan, M.K.; Rahul, A.V.; De Schutter, G.; Van Tittelboom, K. Extrusion-based concrete 3D printing from a material perspective: A state-of-the-art review. Cem. Concr. Compos. 2021, 115, 103855. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-scale digital concrete construction—CONPrint3D concept for on-site, monolithic 3D-printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- Mekonnen, B.G.; Bright, G.; Walker, A. A study on state of the art technology of laminated object manufacturing (Lom). In CAD/CAM, Robotics and Factories of the Future; Springer: New Delhi, India, 2016; pp. 207–216. [Google Scholar] [CrossRef]

- Gupta, R.; Dalakoti, M.; Narasimhulu, A. A Critical Review of Process Parameters in Laminated Object Manufacturing Process BT. In Advances in Materials Engineering and Manufacturing Processes; Singh, I., Bajpai, P.K., Panwar, K., Eds.; Springer: Singapore, 2020; pp. 31–39. [Google Scholar]

- Dermeik, B.; Travitzky, N. Laminated Object Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2020, 22, 2000256. [Google Scholar] [CrossRef]

- Solomon, I.J.; Sevvel, P.; Gunasekaran, J. A review on the various processing parameters in FDM. Mater. Today Proc. 2020, 37, 509–514. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D printing of polymer and associated composite: A review on mechanical properties, defects and treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Dey, A.; Roan Eagle, I.N.; Yodo, N. A Review on Filament Materials for Fused Filament Fabrication. J. Manuf. Mater. Process. 2021, 5, 69. [Google Scholar]

- Parulski, C.; Jennotte, O.; Lechanteur, A.; Evrard, B. Challenges of fused deposition modeling 3D printing in pharmaceutical applications: Where are we now? Adv. Drug Deliv. Rev. 2021, 175, 113810. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S.; Zhang, Y. A review on wire arc additive manufacturing: Monitoring, control and a framework of automated system. J. Manuf. Syst. 2020, 57, 31–45. [Google Scholar] [CrossRef]

- Raut, L.P.; Taiwade, R.V. Wire Arc Additive Manufacturing: A Comprehensive Review and Research Directions. J. Mater. Eng. Perform. 2021, 30, 4768–4791. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, J.; Fan, J.; Zhou, Q.; Peng, Y.; Guo, S. Microstructure and mechanical properties of Ti–6Al–4V alloy fabricated using electron beam freeform fabrication. Vacuum 2019, 167, 364–373. [Google Scholar] [CrossRef]

- Wei, C.; Li, L. Recent progress and scientific challenges in multi-material additive manufacturing via laser-based powder bed fusion. Virtual Phys. Prototyp. 2021, 16, 347–371. [Google Scholar] [CrossRef]

- Charoo, N.A.; Barakh Ali, S.F.; Mohamed, E.M.; Kuttolamadom, M.A.; Ozkan, T.; Khan, M.A.; Rahman, Z. Selective laser sintering 3D printing–an overview of the technology and pharmaceutical applications. Drug Dev. Ind. Pharm. 2020, 46, 869–877. [Google Scholar] [CrossRef] [PubMed]

- Galati, M.; Iuliano, L. A literature review of powder-based electron beam melting focusing on numerical simulations. Addit. Manuf. 2018, 19, 1–20. [Google Scholar] [CrossRef]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting-selection guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Azarniya, A.; Colera, X.G.; Mirzaali, M.J.; Sovizi, S.; Bartolomeu, F.; St Weglowski, M.K.; Wits, W.W.; Yap, C.Y.; Ahn, J.; Miranda, G.; et al. Additive manufacturing of Ti–6Al–4V parts through laser metal deposition (LMD): Process, microstructure, and mechanical properties. J. Alloys Compd. 2019, 804, 163–191. [Google Scholar] [CrossRef]

- Mazzarisi, M.; Campanelli, S.L.; Angelastro, A.; Dassisti, M. Phenomenological modelling of direct laser metal deposition for single tracks. Int. J. Adv. Manuf. Technol. 2020, 111, 1955–1970. [Google Scholar] [CrossRef]

- Manapat, J.Z.; Chen, Q.; Ye, P.; Advincula, R.C. 3D Printing of Polymer Nanocomposites via Stereolithography. Macromol. Mater. Eng. 2017, 302, 1–13. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Qin, Q.; Wang, J. A review of stereolithography: Processes and systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Q.; Wang, S.; Tao, J.; Gou, M. Digital Light Processing Based Three-dimensional Printing for Medical Applications. Int. J. Bioprint. 2019, 6, 242. [Google Scholar] [CrossRef]

- Zhao, Z.; Tian, X.; Song, X. Engineering materials with light: Recent progress in digital light processing based 3D printing. J. Mater. Chem. C 2020, 8, 13896–13917. [Google Scholar] [CrossRef]

- Wiese, M.; Kwauka, A.; Thiede, S.; Herrmann, C. Economic assessment for additive manufacturing of automotive end-use parts through digital light processing (DLP). CIRP J. Manuf. Sci. Technol. 2021, 35, 268–280. [Google Scholar] [CrossRef]

- Tee, Y.L.; Tran, P.; Leary, M.; Pille, P.; Brandt, M. 3D Printing of polymer composites with material jetting: Mechanical and fractographic analysis. Addit. Manuf. 2020, 36, 101558. [Google Scholar] [CrossRef]

- Silva, M.R.; Pereira, A.M.; Sampaio, Á.M.; Pontes, A.J. Assessment of the dimensional and geometric precision of micro-details produced by material jetting. Materials 2021, 14, 1989. [Google Scholar] [CrossRef] [PubMed]

- Kardel, K.; Khoshkhoo, A.; Carrano, A.L. Design guidelines to mitigate distortion in material jetting specimens. Rapid Prototyp. J. 2021, 27, 1148–1160. [Google Scholar] [CrossRef]

- Anderson, T. The Application of 3D Printing for Healthcare. Available online: https://www.itij.com/latest/long-read/application-3d-printing-healthcare (accessed on 2 August 2021).

- Young, R.J.; Lovell, P.A. Introduction to Polymers; CRC Press: Boca Raton, FL, USA, 2011; ISBN 143-9-894-159. [Google Scholar]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. Embracing Additive Manufacturing Technology through Fused Filament Fabrication for Antimicrobial with Enhanced Formulated Materials. Polymers 2021, 13, 1523. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef] [PubMed]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication—A Review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef] [PubMed]

- Mokrane, A.; Boutaous, M.; Xin, S. Process of selective laser sintering of polymer powders: Modeling, simulation, and validation. Comptes Rendus Mec. 2018, 346, 1087–1103. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, A.; Wegener, K. Polymer powders for selective laser sintering (SLS). AIP Conf. Proc. 2015, 1664, 160009. [Google Scholar] [CrossRef] [Green Version]

- Kruth, J.; Levy, G.; Schindel, R.; Craeghs, T.; Yasa, E. Consolidation of Polymer Powders by Selective Laser Sintering. In Proceedings of the 3rd International Conference on Polymers and Moulds Innovations, Ghent, Belgium, 2008; pp. 15–30. Available online: https://www.semanticscholar.org/paper/Consolidation-of-polymer-powders-by-selective-laser-Kruth-Levy/c6737300dba9cba56b08da81fac647ea0a44e1aa (accessed on 8 September 2021).

- Gueche, Y.A.; Sanchez-Ballester, N.M.; Cailleaux, S.; Bataille, B.; Soulairol, I. Selective Laser Sintering (SLS), a New Chapter in the Production of Solid Oral Forms (SOFs) by 3D Printing. Pharmaceutics 2021, 13, 1212. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A review of vat photopolymerization technology: Materials, applications, challenges, and future trends of 3d printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef] [PubMed]

- Revilla-León, M.; Meyers, M.J.; Zandinejad, A.; Özcan, M. A review on chemical composition, mechanical properties, and manufacturing work flow of additively manufactured current polymers for interim dental restorations. J. Esthet. Restor. Dent. 2019, 31, 51–57. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Andreu, A.; Su, P.-C.; Kim, J.-H.; Siang, C.; Kim, S.; Kim, I.; Lee, J.; Noh, J.; Suriya, A.; Yoon, Y.-J. 4D printing materials for Vat Photopolymerization. Addit. Manuf. 2021, 44, 102024. [Google Scholar]

- Davoudinejad, A. Chapter 5—Vat photopolymerization methods in additive manufacturing. In Handbooks in Advanced Manufacturing; Pou, J., Riveiro, A., Davim, J.P.B.T.-A.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 159–181. ISBN 978-0-12-818411-0. [Google Scholar]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Hu, J. Study on STL-based slicing process for 3D printing. In Proceedings of the 28th Annual International, Solid Freeform Fabrication Symposium–An Additive Manufacturing Conference, Göteborg Sweden, 30 June 2001–4 July 2001; pp. 885–895. [Google Scholar]

- Unkovskiy, A.; Bui, P.H.B.; Schille, C.; Geis-Gerstorfer, J.; Huettig, F.; Spintzyk, S. Objects build orientation, positioning, and curing influence dimensional accuracy and flexural properties of stereolithographically printed resin. Dent. Mater. 2018, 34, e324–e333. [Google Scholar] [CrossRef]

- Shaqour, B.; Abuabiah, M.; Abdel-Fattah, S.; Juaidi, A.; Abdallah, R.; Abuzaina, W.; Qarout, M.; Verleije, B.; Cos, P. Gaining a better understanding of the extrusion process in fused filament fabrication 3D printing: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 1279–1291. [Google Scholar] [CrossRef]

- Gautam, R.; Idapalapati, S.; Feih, S. Printing and characterisation of Kagome lattice structures by fused deposition modelling. Mater. Des. 2018, 137, 266–275. [Google Scholar] [CrossRef]

- Garzon-Hernandez, S.; Garcia-Gonzalez, D.; Jérusalem, A.; Arias, A. Design of FDM 3D printed polymers: An experimental-modelling methodology for the prediction of mechanical properties. Mater. Des. 2020, 188, 108414. [Google Scholar] [CrossRef]

- Garzon-Hernandez, S.; Arias, A.; Garcia-Gonzalez, D. A continuum constitutive model for FDM 3D printed thermoplastics. Compos. Part. B Eng. 2020, 201, 108373. [Google Scholar] [CrossRef]

- Andrew, J.J.; Alhashmi, H.; Schiffer, A.; Kumar, S.; Deshpande, V.S. Energy absorption and self-sensing performance of 3D printed CF/PEEK cellular composites. Mater. Des. 2021, 208, 109863. [Google Scholar] [CrossRef]

- Zanjanijam, A.R.; Major, I.; Lyons, J.G.; Lafont, U.; Devine, D.M. Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships. Polymers 2020, 12, 1665. [Google Scholar] [CrossRef]

- Awasthi, P.; Banerjee, S.S. Fused Deposition Modeling of Thermoplastics Elastomeric Materials: Challenges and Opportunities. Addit. Manuf. 2021, 46, 102177. [Google Scholar]

- Aliheidari, N.; Christ, J.; Tripuraneni, R.; Nadimpalli, S.; Ameli, A. Interlayer adhesion and fracture resistance of polymers printed through melt extrusion additive manufacturing process. Mater. Des. 2018, 156, 351–361. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of strength properties of FDM printed parts—A critical review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef]

- Sukindar, N.A.; Ariffin, M.K.A.; Hang Tuah Baharudin, B.T.; Jaafar, C.N.A.; Ismail, M.I.S. Analyzing the effect of nozzle diameter in fused deposition modeling for extruding polylactic acid using open source 3D printing. J. Teknol. 2016, 78, 7–15. [Google Scholar] [CrossRef] [Green Version]

- Triyono, J.; Sukanto, H.; Saputra, R.M.; Smaradhana, D.F. The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material. Open Eng. 2020, 10, 762–768. [Google Scholar] [CrossRef]

- Geng, D.; Zhao, J. Analysis and Optimization of Warpage Deformation in 3D Printing Training Teaching—Taking Jilin University Engineering Training Center as an example. Int. Workshop Educ. Reform Soc. Sci. 2019, 300, 839–842. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.; Ye, W.; Wu, Z.; Geng, P.; Wang, Y.; Zhao, J. Influence of layer thickness, raster angle, deformation temperature and recovery temperature on the shape-memory effect of 3D-printed polylactic acid samples. Materials 2017, 10, 970. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rosli, A.A.; Shuib, R.K.; Ishak, K.M.K.; Hamid, Z.A.A.; Abdullah, M.K.; Rusli, A. Influence of bed temperature on warpage, shrinkage and density of various acrylonitrile butadiene styrene (ABS) parts from fused deposition modelling (FDM). AIP Conf. Proc. 2020, 2267, 1–10. [Google Scholar] [CrossRef]

- Ding, S.; Zou, B.; Wang, P.; Ding, H. Effects of nozzle temperature and building orientation on mechanical properties and microstructure of PEEK and PEI printed by 3D-FDM. Polym. Test. 2019, 78, 105948. [Google Scholar] [CrossRef]

- Chung, M.; Radacsi, N.; Robert, C.; McCarthy, E.D.; Callanan, A.; Conlisk, N.; Hoskins, P.R.; Koutsos, V. On the optimization of low-cost FDM 3D printers for accurate replication of patient-specific abdominal aortic aneurysm geometry. 3D Print. Med. 2018, 4, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Senthilkumaran, K.; Pandey, P.M.; Rao, P.V.M. Influence of building strategies on the accuracy of parts in selective laser sintering. Mater. Des. 2009, 30, 2946–2954. [Google Scholar] [CrossRef]

- Bourell, D.L. Sintering in Laser Sintering. JOM 2016, 68, 885–889. [Google Scholar] [CrossRef]

- Stoia, D.I.; Linul, E.; Marsavina, L. Influence of manufacturing parameters on mechanical properties of porous materials by selective laser sintering. Materials 2019, 12, 871. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martynková, G.S.; Slíva, A.; Kratošová, G.; Barabaszová, K.Č.; Študentová, S.; Klusák, J.; Brožová, S.; Dokoupil, T.; Holešová, S. Polyamide 12 materials study of morpho-structural changes during laser sintering of 3d printing. Polymers 2021, 13, 810. [Google Scholar] [CrossRef]

- Kruth, J.P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef] [Green Version]

- Wudy, K.; Lanzl, L.; Drummer, D. Selective laser sintering of filled polymer systems: Bulk properties and laser beam material interaction. Phys. Procedia 2016, 83, 991–1002. [Google Scholar] [CrossRef] [Green Version]

- Ilkgun, O. Effects of Production Parameters on Porosity and Hole. Master’s Thesis, Middle East Technical University, Ankara, Iran, 2005; pp. 1–144. [Google Scholar]

- Pilipović, A.; Brajlih, T.; Drstvenšek, I. Influence of processing parameters on tensile properties of SLS polymer product. Polymers 2018, 10, 1208. [Google Scholar] [CrossRef] [Green Version]

- Castoro, M. Impact of Laser Power and Build Orientation on the Mechanical Properties of Selectively Laser Sintered Parts. In Proceedings of the National Conference on Undergraduate Research (NCUR), WI, USA, 2013; Available online: http://libjournals.unca.edu/ncur/2013-2/ (accessed on 8 September 2021).

- Konstantinou, I.; Vosniakos, G.C. Rough-cut fast numerical investigation of temperature fields in selective laser sintering/melting. Int. J. Adv. Manuf. Technol. 2018, 99, 29–36. [Google Scholar] [CrossRef]

- Li, X.; Dong, J. Study on Curve of Pe-heating Temperature Control in Selective Laser Sintering. In Proceedings of the 2009 International Symposium on Web Information Systems and Applications, Maynooth, Ireland, 7–8 December 2009; pp. 156–158. [Google Scholar]

- Bagheri, A.; Jin, J. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef] [Green Version]

- Martín-Montal, J.; Pernas-Sánchez, J.; Varas, D. Experimental Characterization Framework for SLA Additive Manufacturing Materials. Polymers 2021, 13, 1147. [Google Scholar] [CrossRef] [PubMed]

- Okolie, O.; Stachurek, I.; Kandasubramanian, B.; Njuguna, J. 3D Printing for Hip Implant Applications: A Review. Polymers 2020, 12, 2682. [Google Scholar] [CrossRef] [PubMed]

- Burke, G.; Devine, D.M.; Major, I. Effect of Stereolithography 3D Printing on the Properties of PEGDMA Hydrogels. Polymers 2020, 12, 2015. [Google Scholar] [CrossRef] [PubMed]

- Mondschein, R.J.; Kanitkar, A.; Williams, C.B.; Verbridge, S.S.; Long, T.E. Polymer structure-property requirements for stereolithographic 3D printing of soft tissue engineering scaffolds. Biomaterials 2017, 140, 170–188. [Google Scholar] [CrossRef]

- Lipson, H.; Kurman, M. Fabricated: The New World of 3D Printing; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Kim, D.; Shim, J.; Lee, D.; Shin, S.; Nam, N. Effects of Post-Curing Time on the Mechanical and Color Properties of Three-Dimensional Printed. Polymers 2020, 12, 2762. [Google Scholar] [CrossRef]

- Muzaffar, A.; Ahamed, M.B.; Deshmukh, K.; Kovářík, T.; Křenek, T.; Pasha, S.K.K. 3D and 4D Printing of pH-Responsive and Functional Polymers and Their Composites; ScienceDirect: Amsterdam, The Netherlands, 2019; ISBN 978-012-816-8-059. [Google Scholar]

- Alsoufi, M.S.; Alhazmi, M.W.; Suker, D.K.; Yunus, M.; Malibari, R.O. From 3D models to FDM 3D prints: Experimental study of chemical treatment to reduce stairs-stepping of semi-sphere profile. AIMS Mater. Sci. 2019, 6, 1086–1106. [Google Scholar] [CrossRef]

- 3D ARGO 500 Printer with Technology for High Viscosity Polymers. Available online: https://www.roboze.com/en/3d-printers/argo-500.html (accessed on 6 August 2021).

- Nexa3D NXV Review—Professional Desktop Resin 3D Printer. Available online: https://www.aniwaa.com/product/3d-printers/nexa3d-nxv/ (accessed on 6 August 2021).

- PICO2—Products—Asiga. Available online: https://www.asiga.com/products/printers/pico2/ (accessed on 6 August 2021).

- Stratasys F900 Is the Ultimate Manufacturing-Grade Production 3D Printer. Available online: https://www.javelin-tech.com/3d/stratasys-3d-printer/stratasys-f900/ (accessed on 6 August 2021).

- HSE 280i HT—Essentium. Available online: https://www.essentium.com/3d-printers/high-speed-extrusion-280/ (accessed on 6 August 2021).

- CreatBot PEEK-300 3D Printer. Available online: https://www.creatbot.com/en/creatbot-peek-300.html (accessed on 6 August 2021).

- Industrial Anisoprinting|Anisoprint. Available online: https://anisoprint.com/solutions/industrial/ (accessed on 6 August 2021).

- INDUSTRY F421—Industrial 3D Printer|3DGence. Available online: https://3dgence.com/3d-printers/industry-f421/ (accessed on 6 August 2021).

- Peek 3D Printer|WASP. Available online: https://www.3dwasp.com/en/peek-3d-printer/ (accessed on 6 August 2021).

- Cincinnati MAAM—Vision Miner. Available online: https://visionminer.com/products/cincinnati-maam?_vsrefdom=adwords&gc_id=1481937543&gclid=Cj0KCQjwu7OIBhCsARIsALxCUaP81y8Nysma5uR6yvTM_fokqlCFO-3m4XdHvodPvjkl7ow8jLFOmToaAkm4EALw_wcB (accessed on 6 August 2021).

- Tractus3D T850P—High Temperature 3D Printer in Our PRO Series. Available online: https://tractus3d.com/products/t850p/ (accessed on 6 August 2021).

- AON M2+ High Temp Industrial 3D Printer|AON3D. Available online: https://www.aon3d.com/aon-m2-industrial-3d-printer/ (accessed on 6 August 2021).

- Kumovis R1 3D Printer for Medical Production|Kumovis. Available online: https://kumovis.com/3d-printer/ (accessed on 6 August 2021).

- Sintratec Kit—Sintratec AG. Available online: https://sintratec.com/product/sintratec-kit/ (accessed on 6 August 2021).

- Desktop SLS Printer—Red Rock 3D. Available online: http://www.redrocksls.com/ (accessed on 6 August 2021).

- Sinterit Lisa PRO—Open SLS 3D Printer. Available online: https://www.sinterit.com/sinterit-lisa-pro/ (accessed on 6 August 2021).

- Fuse 1: Benchtop Selective Laser Sintering (SLS) 3D Printer. Available online: https://formlabs.com/asia/3d-printers/fuse-1/ (accessed on 6 August 2021).

- Sintratec S2—Sintratec AG. Available online: https://sintratec.com/product/sintratec-s2/ (accessed on 6 August 2021).

- The Perfect Professional CO2 Sintering 3D Printer Fully Configurable by the User. Available online: https://www.sharebot.it/en/sharebot-snowwhite-3d-printer/ (accessed on 6 August 2021).

- Gravity—SLS 3D-Printer for Office Use—Wematter.se. Available online: https://wematter3d.com/gravity-sls-3d-printer/ (accessed on 6 August 2021).

- XYZprinting 3D Printers|Mfgpro230_xS. Available online: https://pro.xyzprinting.com/landing-page/en-US/mfgpro230_xs (accessed on 6 August 2021).

- A Revolutionary Thermoplastic 3D Printer|Nexa3D. Available online: https://nexa3d.com/3d-printers/thermoplastic-printers/ (accessed on 6 August 2021).

- EP-P3850 Plastic 3D Printer Brochure—SHINING 3D. Available online: https://www.shining3d.com/downloads/ep-p3850-plastic-3d-printer/ (accessed on 6 August 2021).

- Affordable Industrial SLS® 3D Printer—ProMaker P1000|Prodways FR. Available online: https://www.prodways.com/en/industrial-3d-printers/promaker-p1000/ (accessed on 6 August 2021).

- SLS Printer FORMIGA P 110 Velocis. Available online: https://www.eos.info/en/additive-manufacturing/3d-printing-plastic/eos-polymer-systems/formiga-p-110-velocis (accessed on 6 August 2021).

- ProX SLS 6100-3D Printer|3D Systems. Available online: https://www.3dsystems.com/3d-printers/prox-sls-6100 (accessed on 6 August 2021).

- Farsoon Technologies—Open for Industry. Available online: http://en.farsoon.com/solution_list01_detail/FrontColumns_navigation01-1497537754897FirstColumnId=2&FrontColumns_navigation01-1497537754897SecondColumnId=58&productId=25.html (accessed on 6 August 2021).

- Nyomo Minny Review—Compact, Desktop Resin DLP 3D Printer. Available online: https://www.aniwaa.com/product/3d-printers/nyomo-minny/ (accessed on 6 August 2021).

- XYZprinting Nobel 1.0 Stereolithography 3D Printer 3L10XXUS00C. Available online: https://www.bhphotovideo.com/c/product/1180391-REG/xyzprinting_3l10xxus00c_nobel_printer.html/specs (accessed on 6 August 2021).

- Form Wash and Form Cure Tech Specs. Available online: https://formlabs.com/asia/post-processing/wash-cure/tech-specs/ (accessed on 6 August 2021).

- Photocentric Liquid Crystal Pro|Large High Resolution Prints|Dream 3D. Available online: https://www.dream3d.co.uk/product/photocentric-liquid-crystal-pro/ (accessed on 6 August 2021).

- DWS X Pro S 3D Printer In-Depth Review—Pick 3D Printer. Available online: https://pick3dprinter.com/dws-x-pro-s-review/ (accessed on 6 August 2021).

- Uniontech Large Volume SLA RSPro Series—Europac3D UK. Available online: https://europac3d.com/3d-printers/sla-uniontech-rspro/ (accessed on 6 August 2021).

- 3D Systems ProX 950 3D Printer—Reviews, Specs, Price. Available online: https://www.treatstock.com/machines/item/156-prox-950 (accessed on 6 August 2021).

- Wang, J.; Porter, R.S. On the viscosity-temperature behavior of polymer melts. Rheol. Acta 1995, 34, 496–503. [Google Scholar] [CrossRef]

- Flowers, P.F.; Reyes, C.; Ye, S.; Kim, M.J.; Wiley, B.J. 3D printing electronic components and circuits with conductive thermoplastic filament. Addit. Manuf. 2017, 18, 156–163. [Google Scholar] [CrossRef]

- Hashemi Sanatgar, R.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Hohimer, C.J.; Petrossian, G.; Ameli, A.; Mo, C.; Pötschke, P. 3D printed conductive thermoplastic polyurethane/carbon nanotube composites for capacitive and piezoresistive sensing in soft pneumatic actuators. Addit. Manuf. 2020, 34, 101281. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Introduction and Basic Principles; Higher Education Press: Beijing, China, 2015; ISBN 978-149-392-1-126. [Google Scholar]

- Elkins, K.; Nordby, H.; Janak, C.; Gray, R.W.; Bohn, J.H.; Baird, D.G. Soft elastomers for fused deposition modeling. In Proceedings of the 1997 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 1997; pp. 441–448. Available online: https://repositories.lib.utexas.edu/handle/2152/69898 (accessed on 8 September 2021).

- Pandey, A.; Pradhan, S.K. Investigations into Complete Liquefier Dynamics and Optimization of Process Parameters for Fused Deposition Modeling. Mater. Today Proc. 2018, 5, 12940–12955. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Spoerk, M.; Savandaiah, C.; Arbeiter, F.; Sapkota, J.; Holzer, C. Optimization of mechanical properties of glass-spheres-filled polypropylene composites for extrusion-based additive manufacturing. Polym. Compos. 2019, 40, 638–651. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, A.; Wegener, K. Materials perspective of polymers for additive manufacturing with selective laser sintering. J. Mater. Res. 2014, 29, 1824–1832. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, J.; Sachs, M.; Blümel, C.; Winzer, B.; Toni, F.; Wirth, K.E.; Peukert, W. A novel process route for the production of spherical LBM polymer powders with small size and good flowability. Powder Technol. 2014, 261, 78–86. [Google Scholar] [CrossRef]

- Manufacturing, A. A Critical Review for Synergic Kinetics and Strategies for Enhanced Photopolymerizations for 3D-Printing and Additive Manufacturing. Polymers 2021, 13, 2325. [Google Scholar] [CrossRef]

- Taormina, G.; Sciancalepore, C.; Messori, M.; Bondioli, F. 3D printing processes for photocurable polymeric materials: Technologies, materials, and future trends. J. Appl. Biomater. Funct. Mater. 2018, 16, 151–160. [Google Scholar] [CrossRef] [Green Version]

- Miedzińska, D.; Gieleta, R.; Popławski, A. Experimental study on influence of curing time on strength behavior of sla-printed samples loaded with different strain rates. Materials 2020, 13, 5825. [Google Scholar] [CrossRef]

- Jiang, F.; Drummer, D. Curing kinetic analysis of acrylate photopolymer for additive manufacturing by photo-DSC. Polymers 2020, 12, 1080. [Google Scholar] [CrossRef]

- Papadakis, L.; Chantzis, D.; Salonitis, K. On the energy efficiency of pre-heating methods in SLM/SLS processes. Int. J. Adv. Manuf. Technol. 2018, 95, 1325–1338. [Google Scholar] [CrossRef]

- Wang, R.J.; Wang, L.; Zhao, L.; Liu, Z. Influence of process parameters on part shrinkage in SLS. Int. J. Adv. Manuf. Technol. 2007, 33, 498–504. [Google Scholar] [CrossRef]

- Schmid, M.; Kleijnen, R.; Vetterli, M.; Wegener, K. Influence of the origin of polyamide 12 powder on the laser sintering process and laser sintered parts. Appl. Sci. 2017, 7, 462. [Google Scholar] [CrossRef] [Green Version]

- Dechet, M.A.; Lanzl, L.; Werner, Y.; Drummer, D.; Bück, A.; Peukert, W.; Schmidt, J. Manufacturing and application of pa11-glass fiber composite particles for selective laser sintering. In Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2019. [Google Scholar]

- Fitzharris, E.R.; Watanabe, N.; Rosen, D.W.; Shofner, M.L. Effects of material properties on warpage in fused deposition modeling parts. Int. J. Adv. Manuf. Technol. 2018, 95, 2059–2070. [Google Scholar] [CrossRef]

- Armillotta, A.; Bellotti, M.; Cavallaro, M. Warpage of FDM parts: Experimental tests and analytic model. Robot. Comput. Integr. Manuf. 2018, 50, 140–152. [Google Scholar] [CrossRef]

- Spoerk, M.; Holzer, C.; Gonzalez-Gutierrez, J. Material extrusion-based additive manufacturing of polypropylene: A review on how to improve dimensional inaccuracy and warpage. J. Appl. Polym. Sci. 2020, 137, 48545. [Google Scholar] [CrossRef]

- Yang, T.C. Effect of extrusion temperature on the physico-mechanical properties of unidirectional wood fiber-reinforced polylactic acid composite (WFRPC) components using fused depositionmodeling. Polymers 2018, 10, 976. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Osmanlic, F.; Wudy, K.; Laumer, T.; Schmidt, M.; Drummer, D.; Körner, C. Modeling of laser beam absorption in a polymer powder bed. Polymers 2018, 10, 784. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Suslick, K.S. Encyclopedia of Physical Science and Technology. Sonoluminescence and Sonochemistry Massachusetts; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2001; pp. 1–20. [Google Scholar]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, X.; Jiang, X.N.; Sun, C. Micro-stereolithography of polymeric and ceramic microstructures. Sens. Actuators A Phys. 1999, 77, 149–156. [Google Scholar] [CrossRef]

- Schüller-Ravoo, S.; Teixeira, S.M.; Feijen, J.; Grijpma, D.W.; Poot, A.A. Flexible and elastic scaffolds for cartilage tissue engineering prepared by stereolithography using poly(trimethylene carbonate)-based resins. Macromol. Biosci. 2013, 13, 1711–1719. [Google Scholar] [CrossRef] [PubMed]

- Garay, A.C.; Paese, L.T.; Souza, J.A.; Amico, S.C. Studies on thermal and viscoelastic properties of vinyl ester resin and its composites with glass fiber. Rev. Mater. 2015, 20, 64–71. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Smith, D.E. Filament rheological characterization for fused filament fabrication additive manufacturing: A low-cost approach. Addit. Manuf. 2021, 47, 102208. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Ahuja, I.P.S. Mechanical, thermal and melt flow of aluminum-reinforced PA6/ABS blend feedstock filament for fused deposition modeling. Rapid Prototyp. J. 2018, 24, 1455–1468. [Google Scholar] [CrossRef]

- Wojtyła, S.; Klama, P.; Baran, T. Is 3D printing safe? Analysis of the thermal treatment of thermoplastics: ABS, PLA, PET, and nylon. J. Occup. Environ. Hyg. 2017, 14, D80–D85. [Google Scholar] [CrossRef]

- Trhlíková, L.; Zmeskal, O.; Psencik, P.; Florian, P. Study of the thermal properties of filaments for 3D printing. AIP Conf. Proc. 2016, 1752, 040027. [Google Scholar] [CrossRef]

- Esmizadeh, E.; Tzoganakis, C.; Mekonnen, T.H. Degradation behavior of polypropylene during reprocessing and its biocomposites: Thermal and oxidative degradation kinetics. Polymers 2020, 12, 1627. [Google Scholar] [CrossRef]

- Hao, X.; Guo, Y.; Li, Y.; Yang, Y.; Shen, Y.; Hao, X.; Wang, J. Study on the Structure and Properties of Novel Bio-based Polyamide56 Fiber Compared with Normal Polyamide Fibers BT. In Proceedings of the 2015 International Conference on Materials, Environmental and Biological Engineering, Guilin, China, 28–30 March 2015; Atlantis Press: Amsterdam, The Netherlands, 2015; pp. 147–152. [Google Scholar]

- Wei, S.T.; Zhou, K.; Chao, C. A Comprehensive Investigation on 3D Printing of Polyamide 11 and Thermoplastic Polyurethane via Multi Jet Fusion. Polymers 2021, 13, 2139. [Google Scholar]

- Ituarte, I.F.; Wiikinkoski, O.; Jansson, A. Additive manufacturing of polypropylene: A screening design of experiment using laser-based powder bed fusion. Polymers 2018, 10, 1293. [Google Scholar] [CrossRef] [Green Version]

- Fang, L.; Wang, Y.; Xu, Y. Preparation of polypropylene powder by dissolution-precipitation method for selective laser sintering. Adv. Polym. Technol. 2019, 2019, 5803895. [Google Scholar] [CrossRef] [Green Version]

- Shanmugam, V.; Das, O.; Babu, K.; Marimuthu, U.; Veerasimman, A.; Johnson, D.J.; Neisiany, R.E.; Hedenqvist, M.S.; Ramakrishna, S.; Berto, F. Fatigue behaviour of FDM-3D printed polymers, polymeric composites and architected cellular materials. Int. J. Fatigue 2021, 143, 106007. [Google Scholar] [CrossRef]

- Safai, L.; Cuellar, J.S.; Smit, G.; Zadpoor, A.A. A review of the fatigue behavior of 3D printed polymers. Addit. Manuf. 2019, 28, 87–97. [Google Scholar] [CrossRef]

- Yao, T.; Ouyang, H.; Dai, S.; Deng, Z.; Zhang, K. Effects of manufacturing micro-structure on vibration of FFF 3D printing plates: Material characterisation, numerical analysis and experimental study. Compos. Struct. 2021, 268, 113970. [Google Scholar] [CrossRef]

- Erokhin, K.S.; Gordeev, E.G.; Ananikov, V.P. Revealing interactions of layered polymeric materials at solid-liquid interface for building solvent compatibility charts for 3D printing applications. Sci. Rep. 2019, 9, 1–14. [Google Scholar] [CrossRef]

- Liu, T.; Guessasma, S.; Zhu, J.; Zhang, W.; Nouri, H.; Belhabib, S. Microstructural defects induced by stereolithography and related compressive behaviour of polymers. J. Mater. Process. Technol. 2018, 251, 37–46. [Google Scholar] [CrossRef]

- Bano, S.; Iqbal, T.; Ramzan, N.; Farooq, U. Study of surface mechanical characteristics of abs/pc blends using nanoindentation. Processes 2021, 9, 637. [Google Scholar] [CrossRef]

- Batakliev, T.; Georgiev, V.; Ivanov, E.; Kotsilkova, R.; Di Maio, R.; Silvestre, C.; Cimmino, S. Nanoindentation analysis of 3D printed poly(lactic acid)-based composites reinforced with graphene and multiwall carbon nanotubes. J. Appl. Polym. Sci. 2019, 136, 3–7. [Google Scholar] [CrossRef] [Green Version]

- Mansour, M.; Tsongas, K.; Tzetzis, D. Measurement of the mechanical and dynamic properties of 3D printed polylactic acid reinforced with graphene. Polym. Technol. Mater. 2019, 58, 1234–1244. [Google Scholar] [CrossRef]

- Vǎlean, C.; Marşavina, L.; Mǎrghitaşl, M.; Linul, E.; Razavi, J.; Berto, F. Effect of manufacturing parameters on tensile properties of FDM printed specimens. Procedia Struct. Integr. 2020, 26, 313–320. [Google Scholar] [CrossRef]

- Ding, S.; Kong, L.; Jin, Y.; Lin, J.; Chang, C.; Li, H.; Liu, E.; Liu, H. Influence of the molding angle on tensile properties of FDM parts with orthogonal layering. Polym. Adv. Technol. 2020, 31, 873–884. [Google Scholar] [CrossRef]

- Fountas, N.A.; Kostazos, P.; Pavlidis, H.; Antoniou, V.; Manolakos, D.E.; Vaxevanidis, N.M. Experimental investigation and statistical modelling for assessing the tensile properties of FDM fabricated parts. Procedia Struct. Integr. 2020, 26, 139–146. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Rafiee-Afarani, M.; Zahedi, A.M. Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Compos. Part. B Eng. 2019, 175, 107147. [Google Scholar] [CrossRef]

- Letcher, T.; Waytashek, M. Material property testing of 3D-printed specimen in pla on an entry-level 3D printer. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Rahman, K.M.; Letcher, T.; Reese, R. Mechanical properties of additively manufactured peek components using fused filament fabrication. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Afrose, M.F.; Masood, S.H.; Iovenitti, P.; Nikzad, M.; Sbarski, I. Effects of part build orientations on fatigue behaviour of FDM-processed PLA material. Prog. Addit. Manuf. 2016, 1, 21–28. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Kazmer, D. Three-Dimensional Printing of Plastics, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2017; ISBN 978-032-339-0-408. [Google Scholar]

- Ajoku, U.; Saleh, N.; Hopkinson, N.; Hague, R.; Erasenthiran, P. Investigating mechanical anisotropy and end-of-vector effect in laser-sintered nylon parts. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2006, 220, 1077–1086. [Google Scholar] [CrossRef] [Green Version]

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Cosmi, F.; Dal Maso, A. A mechanical characterization of SLA 3D-printed specimens for low-budget applications. Mater. Today Proc. 2019, 32, 194–201. [Google Scholar] [CrossRef]

- Yang, Y.; Li, L.; Zhao, J. Mechanical property modeling of photosensitive liquid resin in stereolithography additive manufacturing: Bridging degree of cure with tensile strength and hardness. Mater. Des. 2019, 162, 418–428. [Google Scholar] [CrossRef]

- Ahmad, K.W.H.; Mohamad, Z.; Othman, N.; Man, S.H.C.; Jusoh, M. The mechanical properties of photopolymer prepared via 3d stereolithography printing: The effect of uv curing time and anisotropy. Chem. Eng. Trans. 2020, 78, 565–570. [Google Scholar] [CrossRef]

- Borrello, J.; Nasser, P.; Iatridis, J.C.; Costa, K.D. 3D printing a mechanically-tunable acrylate resin on a commercial DLP-SLA printer. Addit. Manuf. 2018, 23, 374–380. [Google Scholar] [CrossRef]

- Chantarapanich, N.; Puttawibul, P.; Sitthiseripratip, K.; Sucharitpwatskul, S.; Chantaweroad, S. Study of the mechanical properties of photo-cured epoxy resin fabricated by stereolithography process. Songklanakarin J. Sci. Technol. 2013, 35, 91–98. [Google Scholar]

- Ayrilmis, N.; Kariz, M.; Kwon, J.H.; Kitek Kuzman, M. Effect of printing layer thickness on water absorption and mechanical properties of 3D-printed wood/PLA composite materials. Int. J. Adv. Manuf. Technol. 2019, 102, 2195–2200. [Google Scholar] [CrossRef]

- Negi, S.; Sharma, R.K.; Dhiman, S. Experimental investigation of sls process for flexural strength improvement of PA-3200GF parts. Mater. Manuf. Process. 2015, 30, 644–653. [Google Scholar] [CrossRef]

- Marsavina, L.; Stoia, D.I. Flexural properties of selectively sintered polyamide and Alumide. Mater. Des. Process. Commun. 2020, 2, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Domingo-Espin, M.; Puigoriol-Forcada, J.M.; Garcia-Granada, A.A.; Llumà, J.; Borros, S.; Reyes, G. Mechanical property characterization and simulation of fused deposition modeling Polycarbonate parts. Mater. Des. 2015, 83, 670–677. [Google Scholar] [CrossRef]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused deposition modeling with polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Tomanik, M.; Żmudzińska, M.; Wojtków, M. Mechanical and Structural Evaluation of the PA12 Desktop Selective Laser Sintering Printed Parts Regarding Printing Strategy. 3D Print. Addit. Manuf. 2021, 1, 1–9. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Leite, J.L.; Vieira, L.F.; Pires, A.T.N.; Roesler, C.R.M. Mechanical properties of PA6/PA12 blend specimens prepared by selective laser sintering. Polym. Test. 2012, 31, 411–416. [Google Scholar] [CrossRef] [Green Version]

- Zhu, W.; Yan, C.; Shi, Y.; Wen, S.; Liu, J.; Shi, Y. Investigation into mechanical and microstructural properties of polypropylene manufactured by selective laser sintering in comparison with injection molding counterparts. Mater. Des. 2015, 82, 37–45. [Google Scholar] [CrossRef]

- Shi, Y.; Chen, J.; Wang, Y.; Li, Z.; Huang, S. Study of the selective laser sintering of polycarbonate and postprocess for parts reinforcement. Proc. Inst. Mech. Eng. Part. L J. Mater. Des. Appl. 2007, 221, 37–42. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part. B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Paggi, R.A.; Lago, A.; Beal, V.E. Microstructural and mechanical characterization of PA12/MWCNTs nanocomposite manufactured by selective laser sintering. Polym. Test. 2011, 30, 611–615. [Google Scholar] [CrossRef] [Green Version]

- Berli, C.; Thieringer, F.M.; Sharma, N.; Müller, J.A.; Dedem, P.; Fischer, J.; Rohr, N. Comparing the mechanical properties of pressed, milled, and 3D-printed resins for occlusal devices. J. Prosthet. Dent. 2020, 124, 780–786. [Google Scholar] [CrossRef]

- Skylar Tibbits, The Emergence of 4D Printing, “TED Talk” 2013. Available online: https://www.ted.com/talks/skylar_tibbits_the_emergence_of_4d_printing?language=yi (accessed on 2 August 2021).

- Bastola, A.K.; Rodriguez, N.; Behl, M.; Soffiatti, P.; Rowe, N.P.; Lendlein, A. Cactus-inspired design principles for soft robotics based on 3D printed hydrogel-elastomer systems. Mater. Des. 2021, 202, 109515. [Google Scholar] [CrossRef]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef]

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-material 3D and 4D printing: A survey. Adv. Sci. 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Joshi, S.; Rawat, K.; Karunakaran, C.; Rajamohan, V.; Mathew, A.T.; Koziol, K.; Thakur, V.K.; Balan, A.S.S. 4D printing of materials for the future: Opportunities and challenges. Appl. Mater. Today 2020, 18, 100490. [Google Scholar] [CrossRef]

- Moreno, M.A.; Gonzalez-Rico, J.; Lopez-Donaire, M.L.; Arias, A.; Garcia-Gonzalez, D. New experimental insights into magneto-mechanical rate dependences of magnetorheological elastomers. Compos. Part. B Eng. 2021, 224, 109148. [Google Scholar] [CrossRef]

- Hu, G.F.; Damanpack, A.R.; Bodaghi, M.; Liao, W.H. Increasing dimension of structures by 4D printing shape memory polymers via fused deposition modeling. Smart Mater. Struct. 2017, 26, 125023. [Google Scholar] [CrossRef]

- Tirado-Garcia, I.; Garcia-Gonzalez, D.; Garzon-Hernandez, S.; Rusinek, A.; Robles, G.; Martinez-Tarifa, J.M.; Arias, A. Conductive 3D printed PLA composites: On the interplay of mechanical, electrical and thermal behaviours. Compos. Struct. 2021, 265, 113744. [Google Scholar] [CrossRef]

- Bodaghi, M.; Damanpack, A.R.; Liao, W.H. Triple shape memory polymers by 4D printing. Smart Mater. Struct. 2018, 27, 65010. [Google Scholar] [CrossRef] [Green Version]

- Zolfagharian, A.; Kaynak, A.; Kouzani, A. Closed-loop 4D-printed soft robots. Mater. Des. 2020, 188, 108411. [Google Scholar] [CrossRef]

- Bodaghi, M.; Serjouei, A.; Zolfagharian, A.; Fotouhi, M.; Rahman, H.; Durand, D. Reversible energy absorbing meta-sandwiches by FDM 4D printing. Int. J. Mech. Sci. 2020, 173, 105451. [Google Scholar] [CrossRef] [Green Version]

- Bastola, A.K.; Paudel, M.; Li, L.; Li, W. Recent progress of magnetorheological elastomers: A review. Smart Mater. Struct. 2020, 29, 123002. [Google Scholar] [CrossRef]

- Bastola, A.K.; Hossain, M. A review on magneto-mechanical characterizations of magnetorheological elastomers. Compos. Part. B Eng. 2020, 200, 108348. [Google Scholar] [CrossRef]

- Merazzo, K.M.J.; Pereira, N.; Lima, A.; Iglesias, M.R.; Fernandes, L.; Lanceros-Mendez, S.; Martins, P. Magnetic materials: A journey from finding north to an exciting printed future. Mater. Horizons 2021. [Google Scholar] [CrossRef]

- Wu, S.; Hu, W.; Ze, Q.; Sitti, M.; Zhao, R. Multifunctional magnetic soft composites: A review. Multifunct. Mater. 2020, 3, 042003. [Google Scholar] [CrossRef]

- Bastola, A.K.; Hoang, V.T.; Li, L. A novel hybrid magnetorheological elastomer developed by 3D printing. Mater. Des. 2017, 114, 391–397. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Q.; Yi, S.; Lin, Z.; Wang, C.; Chen, Z.; Jiang, L. 4D Printing of Magnetoactive Soft Materials for On-Demand Magnetic Actuation Transformation. ACS Appl. Mater. Interfaces 2021, 13, 4174–4184. [Google Scholar] [CrossRef]

- Bastola, A.K.; Paudel, M.; Li, L. Development of hybrid magnetorheological elastomers by 3D printing. Polymers 2018, 149, 213–228. [Google Scholar] [CrossRef]

- Qi, S.; Fu, J.; Xie, Y.; Li, Y.; Gan, R.; Yu, M. Versatile magnetorheological plastomer with 3D printability, switchable mechanics, shape memory, and self-healing capacity. Compos. Sci. Technol. 2019, 183, 107817. [Google Scholar] [CrossRef]

- Cao, X.; Xuan, S.; Sun, S.; Xu, Z.; Li, J.; Gong, X. 3D Printing Magnetic Actuators for Biomimetic Applications. ACS Appl. Mater. Interfaces 2021, 13, 30127–30136. [Google Scholar] [CrossRef] [PubMed]

- Hupfeld, T.; Salamon, S.; Landers, J.; Sommereyns, A.; Doñate-Buendía, C.; Schmidt, J.; Wende, H.; Schmidt, M.; Barcikowski, S.; Gökce, B. 3D printing of magnetic parts by laser powder bed fusion of iron oxide nanoparticle functionalized polyamide powders. J. Mater. Chem. C 2020, 8, 12204–12217. [Google Scholar] [CrossRef]

- Lantean, S.; Barrera, G.; Pirri, C.F.; Tiberto, P.; Sangermano, M.; Roppolo, I.; Rizza, G. 3D Printing of Magnetoresponsive Polymeric Materials with Tunable Mechanical and Magnetic Properties by Digital Light Processing. Adv. Mater. Technol. 2019, 4, 1–10. [Google Scholar] [CrossRef]

- Ji, Z.; Yan, C.; Yu, B.; Wang, X.; Zhou, F. Multimaterials 3D Printing for Free Assembly Manufacturing of Magnetic Driving Soft Actuator. Adv. Mater. Interfaces 2017, 4, 1–6. [Google Scholar] [CrossRef]

- Nagarajan, B.; Mertiny, P.; Qureshi, A.J. Magnetically loaded polymer composites using stereolithography—Material processing and characterization. Mater. Today Commun. 2020, 25, 101520. [Google Scholar] [CrossRef]

- Hossain, M.; Liao, Z. An additively manufactured silicone polymer: Thermo-viscoelastic experimental study and computational modelling. Addit. Manuf. 2020, 35, 101395. [Google Scholar] [CrossRef]

- Bodaghi, M.; Noroozi, R.; Zolfagharian, A.; Fotouhi, M.; Norouzi, S. 4D Printing Self-Morphing Structures. Materials 2019, 12, 1353. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, W.; Zhang, F.; Leng, J.; Liu, Y. Personalized 4D printing of bioinspired tracheal scaffold concept based on magnetic stimulated shape memory composites. Compos. Sci. Technol. 2019, 184, 107866. [Google Scholar] [CrossRef]

- Dohmen, E.; Saloum, A.; Abel, J. Field-structured magnetic elastomers based on thermoplastic polyurethane for fused filament fabrication. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2020, 378, 20190257. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Singh, R.; Singh, T.P.; Batish, A. On mechanical characterization of 3-D printed PLA-PVC-wood dust-Fe3O4 composite. J. Thermoplast. Compos. Mater. 2019, 0892705719879195. [Google Scholar] [CrossRef]

- Prem, N.; Sindersberger, D.; Monkman, G.J. Mini-Extruder for 3D Magnetoactive Polymer Printing. Adv. Mater. Sci. Eng. 2019, 2019, 8715718. [Google Scholar] [CrossRef] [Green Version]

- Calascione, T.M.; Fischer, N.A.; Lee, T.J.; Thatcher, H.G.; Nelson-Cheeseman, B.B. Controlling magnetic properties of 3D-printed magnetic elastomer structures via fused deposition modeling. AIP Adv. 2021, 11, 25223. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, L.; Zheng, Z.; Liu, Y.; Leng, J. Magnetic programming of 4D printed shape memory composite structures. Compos. Part. A Appl. Sci. Manuf. 2019, 125, 105571. [Google Scholar] [CrossRef]

- Wu, H.; Wang, O.; Tian, Y.; Wang, M.; Su, B.; Yan, C.; Zhou, K.; Shi, Y. Selective Laser Sintering-Based 4D Printing of Magnetism-Responsive Grippers. ACS Appl. Mater. Interfaces 2021, 13, 12679–12688. [Google Scholar] [CrossRef]

- Shinoda, H.; Azukizawa, S.; Maeda, K.; Tsumori, F. Bio-mimic motion of 3D-printed gel structures dispersed with magnetic particles. J. Electrochem. Soc. 2019, 166, B3235. [Google Scholar] [CrossRef]

- Zhu, W.; Li, J.; Leong, Y.J.; Rozen, I.; Qu, X.; Dong, R.; Wu, Z.; Gao, W.; Chung, P.H.; Wang, J.; et al. 3D-Printed Artificial Microfish. Adv. Mater. 2015, 27, 4411–4417. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shao, G.; Ware, H.O.T.; Li, L.; Sun, C. Rapid 3D Printing Magnetically Active Microstructures with High Solid Loading. Adv. Eng. Mater. 2020, 22, 1900911. [Google Scholar] [CrossRef]

- Shao, G.; Ware, H.O.T.; Huang, J.; Hai, R.; Li, L.; Sun, C. 3D printed magnetically-actuating micro-gripper operates in air and water. Addit. Manuf. 2021, 38, 101834. [Google Scholar] [CrossRef]

- Domingo-Roca, R.; Jackson, J.C.; Windmill, J.F.C. 3D-printing polymer-based permanent magnets. Mater. Des. 2018, 153, 120–128. [Google Scholar] [CrossRef] [Green Version]

- Msallem, B.; Sharma, N.; Cao, S.; Halbeisen, F.S.; Zeilhofer, H.-F.; Thieringer, F.M. Evaluation of the Dimensional Accuracy of 3D-Printed Anatomical Mandibular Models Using FFF, SLA, SLS, MJ, and BJ Printing Technology. J. Clin. Med. 2020, 9, 817. [Google Scholar] [CrossRef] [Green Version]

| AM Technology | Name | Dimension of Printer (mm) | Print Volume (cm3) | Layer Thickness (mm) | Available Material/Type | Ref. | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| FDM | Stratasys F900 | 914 × 609 × 914 | 508,756.16 | 0.127–0.5 | PLA | ABS | PEEK | Nylon | ULTEM | [128] |

| Essentium HSE 280i HT | 695 × 495 × 600 | 206,415 | 0.1–0.55 | PLA | ABS | PEEK | Nylon | ULTEM | [129] | |

| CreatBot PEEK-300 | 300 × 300 × 400 | 36,000 | 0.04–0.4 | PLA | ABS | PEEK | Nylon | ULTEM | [130] | |

| Anisoprint ProM IS 500 | 600 × 420 × 300 | 75,600 | 0.06 | PLA | ABS | PEEK | Nylon | ULTEM | [131] | |

| 3DGence F420 | 380 × 380 × 420 | 60,648 | 0.05 | PLA | ABS | PEEK | Nylon | ULTEM | [132] | |

| Roboze Argo 500 | 500 × 500 × 500 | 125,000 | 0.025–0.2 | PLA | ABS | PEEK | Nylon | ULTEM | [125] | |

| WASP 4070 Tech | 400 × 400 × 700 | 112,000 | 0.1 | PLA | ABS | PEEK | Nylon | ULTEM | [133] | |

| Cincinnati MAAM | 1050 × 1015 × 1015 | 1,081,736.25 | 0.2 | PLA | ABS | PEEK | Nylon | ULTEM | [134] | |

| Tractus 3D T850P | 280 × 280 × 400 | 31,360 | 0.01–0.8 | PLA | ABS | PEEK | Nylon | ULTEM | [135] | |

| AON-M2+ | 450 × 450 × 640 | 129,600 | 0.05–0.5 | PLA | ABS | PEEK | Nylon | ULTEM | [136] | |

| Kumovis R1 | 180 × 180 × 150 | 4860 | 0.1–0.4 | PLA | ABS | PEEK | Nylon | ULTEM | [137] | |

| Ultimaker S5 | 330 × 340 × 300 | 33,660 | 0.02–0.25 | PLA | ABS | PEEK | Nylon | ULTEM | ||

| SLS | Sintratec Kit | 100 × 100 × 100 | 1000 | 0.05–0.15 | PA 12 | PA 11 | TPU | TPE | PP | [138] |

| Red Rock 3D | 180 × 180 × 180 | 5832 | 0.1 | PA 12 | PA 11 | TPU | TPE | PP | [139] | |

| Sinterit Lisa Pro | 110 × 160 × 245 | 4312 | 0.05 | PA 12 | PA 11 | TPU | TPE | PP | [140] | |

| Formlabs Fuse 1 | 165 × 165 × 300 | 8167.5 | 0.1 | PA 12 | PA 11 | TPU | TPE | PP | [141] | |

| Sintratec S2 | ⌀160 × 400 | 8038.4 | 0.1 | PA 12 | PA 11 | TPU | TPE | PP | [142] | |

| Sharebot SnowWhite 2 | 100 × 100 × 100 | 1000 | 0.05 | PA 12 | PA 11 | TPU | TPE | PP | [143] | |

| Wematter Gravity | 300 × 300 × 300 | 27,000 | 0.1 | PA 12 | PA 11 | TPU | TPE | PP | [144] | |

| XYZ printing MfgPro230 xS | 230 × 230 × 230 | 12,167 | 0.08–0.2 | PA 12 | PA 11 | TPU | TPE | PP | [145] | |

| Nexa3D QLS350 | 350 × 350 × 400 | 49,000 | 0.05–0.2 | PA 12 | PA 11 | TPU | TPE | PP | [146] | |

| Shining 3D EP-P3850 | 380 × 380 × 500 | 72,200 | 0.08–0.3 | PA 12 | PA 11 | TPU | TPE | PP | [147] | |

| Prodways Promaker P1000 | 300 × 300 × 360 | 32,400 | 0.06–0.12 | PA 12 | PA 11 | TPU | TPE | PP | [148] | |

| EOS Formiga P 110 Velocis | 200 × 250 × 330 | 16,500 | 0.06–0.12 | PA 12 | PA 11 | TPU | TPE | PP | [149] | |

| 3D Systems ProX SLS 6100 | 381 × 330 × 460 | 57,835.8 | 0.08–0.15 | PA 12 | PA 11 | TPU | TPE | PP | [150] | |

| Farsoon eForm | 250 × 250 × 320 | 20,000 | 0.06–0.3 | PA 12 | PA 11 | TPU | TPE | PP | [151] | |

| SLA | Nyomo’s Minny | 44 × 28 × 70 | 86.24 | 0.01 | Standard resin | Castable | Bio compatible | Flexible | Clear | [152] |

| Asiga’s Pico 2 | 51 × 32 × 76 | 124.032 | 0.001 | Standard resin | Castable | Bio compatible | Flexible | Clear | [127] | |

| XYZprinting’s Nobel 1.0 A | 128 × 128 × 200 | 3276.8 | 0.025–0.1 | Standard resin | Castable | Bio compatible | Flexible | Clear | [153] | |

| Formlabs Form 2 | 145 × 145 × 175 | 3679.375 | 0.025–0.2 | Standard resin | Castable | Bio compatible | Flexible | Clear | [154] | |

| Photocentric’s Liquid Crystal | 121 × 68 × 160 | 1316.48 | 0.05 | Standard resin | Castable | Bio compatible | Flexible | Clear | [155] | |

| Nexa3D’s the NXV | 220 × 120 × 380 | 10,032 | 0.03 | Standard resin | Castable | Bio compatible | Flexible | Clear | [126] | |

| DWS’s XPRO S | 300 × 300 × 300 | 27,000 | 0.01 | Standard resin | Castable | Bio compatible | Flexible | Clear | [156] | |

| UnionTech’s RSPro 800 | 800 × 800 × 550 | 352,000 | 0.07–0.25 | Standard resin | Castable | Bio compatible | Flexible | Clear | [157] | |

| 3D Systems’ ProX 950 | 1500 × 750 × 550 | 618,750 | 0.01 | Standard resin | Castable | Bio compatible | Flexible | Clear | [158] | |

| AM Technique | Material | ||

|---|---|---|---|

| FDM | Thermoplastic filament | Semi-crystalline | PEEK |

| PVDF | |||

| PP | |||

| PLA | |||

| TPU | |||

| TPE | |||

| PPS | |||

| PCL | |||

| PLGA | |||

| PEVA | |||

| PA6 | |||

| PA12 | |||

| POM | |||

| PET | |||

| Amorphous | PEI | ||

| PAI | |||

| PPSU | |||

| PC | |||

| PVA | |||

| HIPS | |||

| PEKK | |||

| ASA | |||

| ABS | |||

| PMMA | |||

| PS | |||

| SLS | Thermoplastic powder | Semi-crystalline | PA12 |

| PA11 | |||

| PA6 | |||

| PET | |||

| PLA | |||

| PCL | |||

| TPU | |||

| POM | |||

| PEEK | |||

| PEK | |||

| PEKK | |||

| Amorphous | PC | ||

| PMMA | |||

| PS | |||

| PI | |||

| PSU | |||

| PES | |||

| PVA | |||

| SLA | Resins | Polyester | PPF |

| PLA | |||

| PCL | |||

| PCL/PEG/Chitosan | |||

| Polycarbonate | PTMC | ||

| PTMC/Gelatin | |||

| Trimethylolpropane Carbonate | |||

| Polyether | PEG | ||

| PEG/Chitosan | |||

| PEO/PEG | |||

| Poly tetrahydrofuran ether | |||

| Material | Tm (°C) | Tg (°C) | Printing Temperature (°C) | Temperature of Degradation (°C) | Ref. | |

|---|---|---|---|---|---|---|

| Thermoplastic Filament | ABS | - | 105 | 230–250 | 380–430 | [189,190] |

| PLA | 150 | - | 200–235 | 300–400 | [190,191] | |

| PET | 255 | 75 | 160–210 | 350–480 | [190,191] | |

| PP | 165 | −10 | 230–260 | 300–500 | [191,192] | |

| PA6 | 215 | 46 | 419.8 | 220–270 | [189,193] |

| Material | Tm | Tm, Onset | Tc, Onset | Sintering Window | Ref. | |

|---|---|---|---|---|---|---|

| Thermoplastic powder | PA12 | 185.6 | 178.0 | 158.6 | 19.4 | [108] |

| PA11 | 202.9 | 189.2 | 168.3 | 20.9 | [194] | |

| TPU | 144.4 | 122.2 | 123.9 | 1.7 | [194] | |

| PC | 167.1 | 157.0 | 121.9 | 35.1 | [195] | |

| PP | 182.3 | 177.1 | 151.3 | 19.5 | [196] |

| Polymer | Supplier | Print Setting | Test Standard | Print Orientation | Tensile Modulus (MPa) | Tensile Strength (MPa) | Elongation (%) | Ref. | |

|---|---|---|---|---|---|---|---|---|---|

| Thermoplastic Filament | PLA | 3D Systems | 100% infill Layer thickness 0.2 mm | ASTM D638 | XYZ | 1538 | 38.7 | - | [212] |

| YXZ | 1246 | 31.1 | - | ||||||

| XYZ | 1350 | 33.6 | - | ||||||

| ABS | Qimei Stock, China | 100% infill | ASTM D638 | XYZ | 1200 | 37 | - | [210] | |

| PEEK | Arevo Labs | 100% infill Bed temperature 230 °C | ASTM D638 | XYZ | 2871 | 71.36 | 5.01 | [211] | |

| PC | Stratasys, USA | 100% infill | ASTM D638 | XYZ | 2410 | 54.6 | 4.22 | [225] | |

| PP | 100% infill Nozzle temperature 165 °C | DIN 53504-S3a | XYZ 0° | 1230 | 34.3 | - | [226] | ||

| XYZ 45° | 1000 | 32.0 | - | ||||||

| XYZ 90° | 1050 | 33.0 | - | ||||||

| ThermoplasticPowder | PA-12 | Sinterit | Laser thickness 0.175 mm | ISO 527 | ZXY 0° | 864 ± 72 | 42.5 ± 3.1 | 13.1 ± 2.3 | [227] |

| ZXY 30° | 690 ± 143 | 28.1 ± 8.4 | 6.7 ± 1.6 | ||||||

| ZXY 45° | 613 ± 27 | 16.0 ± 2.3 | 2.7 ± 0.3 | ||||||

| ZXY 60° | 694 ± 32 | 25.6 ± 8.9 | 8.4 ± 5.7 | ||||||

| ZXY 90° | 426 ± 150 | 17.1 ± 10.0 | 6.0 ± 3.4 | ||||||

| Duraform | Layer thickness 0.1 mm Part bed temperature 175 °C Laser power 38 W | ISO 527-1 | ZXY | 1675 ± 41 | 47.6 ± 1.5 | 6.6 ± 0.7 | [176] | ||

| YXZ | 1610 ± 61 | 40.6 ± 3.4 | 3.7 ± 0.6 | ||||||

| Orgasol IS | Layer thickness 0.1 mm Part bed temperature 164 °C Laser power 48 W | ISO 527-1 | ZXY | 1700 ± 25 | 54.7 ± 0.7 | 12 ± 0.4 | [176] | ||

| YXZ | 1580 ± 21 | 29.3 ± 3.6 | 1.9 ± 0.3 | ||||||

| EOSINT | Laser power 3.33 W Powder bed temperature 140 °C | 205.0 ± 29.3 | 57.7 ± 10.3 | 11.5 ± 1.3 | [228] | ||||

| PA-11 | Building chamber temp 157 °C Powder bed temperature 177 °C Layer thickness 0.3 mm | ISO 527-2 | 7.1 ± 0.5 | 5.9 ± 0.5 | [177] | ||||

| PP | Powder bed temperature 150 °C Layer thickness 0.12 mm | - | 27.9 | - | [196] | ||||

| Trial Corporation | Powder bed temperature 150 °C Laser power 13.75 W Layer thickness 0.15 mm | ISO 527-2 | ZYX | 599.1 ± 14.1 | 19.9 ± 3.5 | 122.25 | [229] | ||

| PA 6 | Mazzafero Tecnopolímeros S.A. | Powder bed temperature 120 °C Laser power 2.34 W | 166.6 ± 77.8 | 62.4 ± 16.0 | 10.9 ± 3.7 | [228] | |||

| PC | HRPS | Laser power 13.5 W Layer thickness 0.15 mm Bed temperature 100 °C | ISO527-2 | ZYX | 40.12 | 1.1 | 5.05 | [230] | |

| Resin | PR 48 | Autodesk, USA | Layer thickness 50 µm Print resolution | ZXY 0° | 723 | - | - | [219] | |

| ZXY 45° | 350 | - | - | ||||||

| ZXY 90° | 376 | - | - | ||||||

| ZXY 0° | 901.4 | - | - | ||||||

| ZXY 45° | 667.1 | - | - | ||||||

| ZXY 90° | 182.2 | - | - | ||||||

| Clear V4 | Formlabs | Layer thickness 50 µm | ISO 527 | Mean 0,15°,30°,45°,60°,75°,90° | 2298 | 60.8 | 8.05 | [217] | |

| Watershed 11122 | DSM Somos | Layer thickness 0.175 mm Laser power 2.5 W Laser scanning speed 3200 mm/s | ASTM D638 | XYZ 0° | 37.75 ± 1.82 | 3.45 ± 0.11 | 11.67 ± 4.97 | [221] | |

| XYZ 45° | 43.25 ± 0.98 | 3.51 ± 0.03 | 7.60 ± 3.48 | ||||||

| XYZ 90°/YXZ | 38.24 ± 2.22 | 3.26 ± 0.08 | 8.53 ± 4.29 | ||||||

| XZY 0° | 46.07 ± 0.99 | 3.54 ± 0.07 | 9.27 ± 1.10 | ||||||

| XZY 45° | 47.70 ± 0.52 | 3.65 ± 0.02 | 9.00 ± 3.57 | ||||||

| XZY 90°/YZX | 45.72 ± 0.48 | 3.50 ± 0.05 | 6.60 ± 0.30 | ||||||

| Monomer: EGPEA Crosslinker: 1,6-hexanediol diacrylate Photoinitiator: 2-Benzyl-2-(dimethylamino)-4′-morpholinobutyrophenone | Monomer 1, crosslinker 0.4 Monomer 1, crosslinker 1.0 | ASTM D638 | 18.026 ± 0.302 | 1.861 ± 0.435 | 0.106 ± 0.025 | [220] | |||

| 36.586 ± 1.210 | 2.243 ± 0.709 | 0.062 ± 0.021 | |||||||

| Polymer | Supplier | Print Settings | Sample Orientation | Flexural Modulus (MPa) | Flexural Strength (MPa) | Elongation (%) | Ref. | |

|---|---|---|---|---|---|---|---|---|

| Thermoplastic Filament | ABS | 100% infill | XYZ | 1750 | 60 | 3 | [231] | |

| PLA | 100% infill Bed temperature 230 °C Nozzle temperature 210 °C | XYZ 0° | 3187 | 102.203 | 10.6 | [209] | ||

| XYZ 45° | 2985 | 90.649 | 7.8 | |||||

| XYZ 90° | 3000 | 86.136 | 4.5 | |||||

| PEEK | Arevo Labs | 100% infill Bed temperature 230 °C Nozzle temperature 340 °C | XYZ 0° | 1972 | 114 | 10.6 | [211] | |

| XYZ 90° | 1954 | 83.59 | 5.81 | |||||

| XYZ 0° and 90° | 2146 | 88.70 | 6.58 | |||||

| ThermoplasticPowder | PA-12 | Duraform, 3D Systems | 546 ± 28 | 86 ± 5 | 11 ± 0.5 | [232] | ||

| PC | Laser power 13.5 W Layer thickness 0.15 mm Bed temperature 100 °C | 93.83 | 2.48 | - | [230] | |||

| PA 2200 | EOS | Laser power 25 W Building chamber temperature 170 °C | XZY 0° | 551.24 + −5.6 | 59.23 + −4.1 | 4.9 + −0.74 mm | ||

| XZY 45° | 433.05 + −61.4 | 46.25 + −6.4 | 4.96 + −0.56 mm | |||||

| XZY 90° | 345.39 + −41.5 | 19.89 + −2.8 | 3.28 + −1.51 mm | |||||

| Resin | Freeprint splint | DETAX GmbH | - | 19.5 ± 2.5 | - | [233] | ||

| LuxaPrint Ortho Plus | DMG GmbH | - | 39.3 ± 2.0 | - | ||||

| Nextdent Ortho Clear | Vertex-Dental B.V. | - | 91.3 ± 5.9 | - | ||||

| Dental SG resin | Formlabs | Layer thickness 0.05 mm | ZXY 0° | 1654.35 ± 152.27 | 117.48 ± 12.39 | - | [88] | |

| ZXY 45° | 1467.56 ± 89.36 | 130.73 ± 5.12 | - | |||||

| ZXY 90° | 1456.73 ± 149.83 | 135.69 ± 5.93 | - | |||||

| Fused Deposition Modelling (FDM) | Selective Laser Sintering (SLS) | Stereolithography (SLA) | |

|---|---|---|---|

| Operational principal | Material extrusion | Laser sintering | UV curing |

| Resolution |  |  |  |

| Accuracy |  |  |  |

| Surface finish |  |  |  |

| Design complexity |  |  |  |

| Ease of use |  |  |  |

| Printing time |  |  |  |

| Advantages | Fast printing process Low part production cost Wide variety of materials are required | Functional parts Design freedom No support structures is required | High-resolution parts can be achieved Wide range of functional applications High accuracy |

| Limitations | Poor surface finish Support structures are required | Rough surface finish Lengthy printing time | Limited materials High maintenance cost is required |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. https://doi.org/10.3390/polym13183101

Kafle A, Luis E, Silwal R, Pan HM, Shrestha PL, Bastola AK. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers. 2021; 13(18):3101. https://doi.org/10.3390/polym13183101

Chicago/Turabian StyleKafle, Abishek, Eric Luis, Raman Silwal, Houwen Matthew Pan, Pratisthit Lal Shrestha, and Anil Kumar Bastola. 2021. "3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA)" Polymers 13, no. 18: 3101. https://doi.org/10.3390/polym13183101