An Analysis of Polymer Gear Wear in a Spur Gear Train Made Using FDM and FFF Methods Based on Tooth Surface Topography Assessment

Abstract

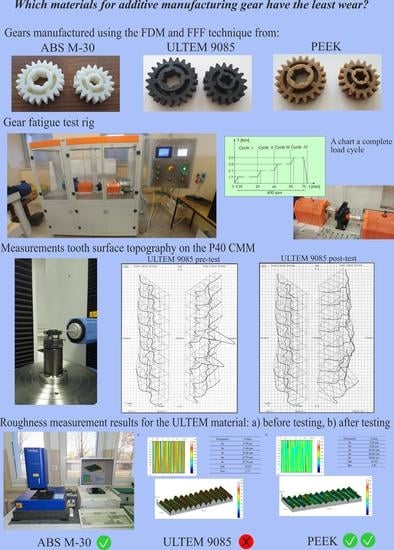

:1. Introduction

2. Materials and Methods

2.1. Research Object

2.2. Materials

2.3. Additive Manufacturing

2.4. Gear Fatigue Test Rig

2.5. Rig Tests on the Gear

2.6. Tooth Surface Geometrical Accuracy Measurements

2.6.1. Measurements on the P40 CMM

2.6.2. Tooth Flank Surface Geometry Measurements

- Arithmetical mean of absolute values of ordinates within the defined area (A)—Sa:

- Root-mean-square of absolute values of ordinates within the defined area (A)—Sq:

- Greatest value of the height of the apex within the defined area—Sp;

- Greatest value of the depth of the concavity within the defined area—Sv;

- The sum of the greatest value of the height of the apex and the greatest value of the depth of the concavity within the defined area—Sz:

- Quotient of the mean value of cube ordinates and cube Sq within the defined area (A)—Ssk:

- Quotient of the mean value of fourth power ordinates and fourth power Sq within the defined area (A)—Sku:

3. Results and Discussion

- Shore D digital hardness tester (durometer), model HDD 100-1 (ISO 868) [76].

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wohlers, T.T.; Campbell, I.; Diegel, O.; Huff, R.; Kowen, J. Wohlers Report 2020—3D Printing and Additive Manufacturing Global State of the Industry; Wohlers Associates: Fort Collins, CO, USA, 2018; ISBN 978-0-9913332-6-4. [Google Scholar]

- Bonaiti, L.; Concli, F.; Gorla, C.; Rosa, F. Bending fatigue behaviour of 17-4 PH gears produced via selective laser melting. Procedia Struct. Integr. 2019, 24, 764–774. [Google Scholar] [CrossRef]

- Batsch, M.; Markowski, T.; Legutko, S.; Krolczyk, G.M. Measurement and mathematical model of convexo-concave Novikov gear mesh. Measurement 2018, 125, 516–525. [Google Scholar] [CrossRef]

- Gomà Ayats, J.R.; Diego-Ayala, U.; Minguella Canela, J.; Fenollosa, F.; Vivancos, J. Hypergraphs for the analysis of complex mechanisms comprising planetary gear trains and other variable or fixed transmissions. Mech. Mach. Theory 2012, 51, 217–229. [Google Scholar] [CrossRef]

- Drewniak, J.; Kopeć, J.; Zawiślak, S. Kinematical analysis of variants of wind turbine drive by means of graphs. In Graph-Based Modelling in Engineering; Part of the Mechanisms and Machine Science Book Series; Springer: Cham, Switzerland, 2016; Volume 42, pp. 81–95. [Google Scholar]

- Peruń, G. Simulation investigations of influence of tooth depth coefficient on dynamic phenomena in toothed gear. Appl. Mech. Mater. 2016, 817, 41–46. [Google Scholar] [CrossRef]

- Kim, W.; Lee, J.Y.; Chung, J. Dynamic analysis for a planetary gear with time-varying pressure angles and contact ratios. J. Sound Vib. 2012, 331, 883–901. [Google Scholar] [CrossRef]

- Li, C.J.; Lee, H. Gear fatigue crack prognosis using embedded model, gear dynamic model and fracture mechanics. Mech. Syst. Signal Process. 2005, 19, 836–846. [Google Scholar] [CrossRef]

- Feng, Z.; Liang, M. Fault diagnosis of wind turbine planetary gearbox under nonstationary conditions via adaptive optimal kernel time-frequency analysis. Renew. Energy 2014, 66, 468–477. [Google Scholar] [CrossRef]

- Lei, Y.; Kong, D.; Lin, J.; Zuo, M.J. Fault detection of planetary gearboxes using new diagnostic parameters. Meas. Sci. Technol. 2012, 23. [Google Scholar] [CrossRef]

- Mao, K. Gear tooth contact analysis and its application in the reduction of fatigue wear. Wear 2007, 262, 1281–1288. [Google Scholar] [CrossRef]

- Qu, Y.; He, D.; Yoon, J.; Van Hecke, B.; Bechhoefer, E.; Zhu, J. Gearbox tooth cut fault diagnostics using acoustic emission and vibration sensors. A comparative study. Sensors 2014, 14, 1372–1393. [Google Scholar] [CrossRef]

- Wojnar, G.; Juzek, M. The impact of non-parallelism of toothed gear shafts axes and method of gear fixing on gearbox components vibrations. Acta Mech. Autom. 2018, 12, 165–171. [Google Scholar] [CrossRef] [Green Version]

- Folęga, P.; Burdzik, R.; Wojnar, G. The optimization of the ribbing of gear transmission housing used in transportation machines. J. Vibr. 2016, 18, 2372–2383. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Olmi, G.; Vincenzi, N. A Practical Approach to Gear Design and Lubrication: A Review. Lubricants 2020, 8, 84. [Google Scholar] [CrossRef]

- Klein-Meuleman, P.; Walton, D.; Dearn, K.D.; Weale, D.J.; Driessen, I. Minimization of transmission errors in highly loaded plastic gear trains. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2007, 221, 1117–1129. [Google Scholar] [CrossRef]

- Karimpour, M.; Dearn, K.D.; Walton, D. A kinematic analysis of meshing polymer gear teeth. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2010, 224, 101–115. [Google Scholar] [CrossRef]

- Düzcükoglu, H. PA 66 spur gear durability improvement with tooth width modification. Mater. Des. 2009, 30, 1060–1067. [Google Scholar] [CrossRef]

- Mao, K.; Langlois, P.; Hu, Z.; Alharbi, K.; Xu, X.; Milson, M.; Li, W.; Hooke, C.J.; Chetwynd, D. The wear and thermal mechanical contact behaviour of machine cut polymer gears. Wear 2015, 332, 822–826. [Google Scholar] [CrossRef]

- Mao, K.; Greenwood, D.; Ramakrishnan, R.; Goodship, V.; Shrouti, C.; Chetwynd, D.; Langlois, P. The wear resistance improvement of fibre reinforced polymer composite gears. Wear 2019, 426-427, 1033–1039. [Google Scholar] [CrossRef]

- Singh, A.K.; Siddhartha; Singh, P.K. Polymer spur gears behaviours under different loading conditions: A review. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 210–228. [Google Scholar] [CrossRef]

- Mao, K.; Chetwynd, D.G.; Millson, M. A new method for testing polymer gear wear rate and performance. Polym. Test. 2020, 82. [Google Scholar] [CrossRef]

- Pogačnik, A.; Tavčar, J. An accelerated multilevel test and design procedure for polymer gears. Mater. Des. 2015, 65, 961–973. [Google Scholar] [CrossRef]

- Dearn, K.D.; Hoskins, T.J.; Andrei, L.; Walton, D. Lubrication regimes in high-performance polymer spur gears. Adv. Tribol. 2013, 2013. [Google Scholar] [CrossRef] [Green Version]

- Pisula, J. Geometric analysis of injection-molded polymer gears. Polimery 2021, 66, 56–62. [Google Scholar] [CrossRef]

- Pisula, J. Geometric accuracy analysis of polymer spiral bevel gears carried out in a measurement system based on the industry 4.0 structure. Polimery 2019, 64, 353–360. [Google Scholar] [CrossRef] [Green Version]

- Dziubek, T.; Oleksy, M. Application of ATOS II optical system in the techniques of rapid prototyping of epoxy resin-based gear models. Polimery 2017, 62, 44–52. [Google Scholar] [CrossRef]

- Pisula, J.; Dziubek, T.; Przeszłowski, Ł. A comparison of the accuracy of bevel gear teeth obtained by means of selected RP techniques and the removal machining method. Mach. Dyn. Res. 2016, 40, 147–161. [Google Scholar]

- Pisula, J.; Dziubek, T.; Przeszłowski, L.; Budzik, G. Evaluation of geometrical parameters of a spur gear manufactured in an incremental process from GP1 steel. In Industrial Measurements in Machining; Królczyk, G.M., Niesłony, P., Królczyk, J., Eds.; Part of the Lecture Notes in Mechanical Engineering Book Series; Springer: Cham, Switzerland, 2020; Volume 975, pp. 109–127. [Google Scholar]

- Dizon, J.R.; Espera, A.; Chen, Q.; Advincula, R. Mechanical characterization of 3D printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Brischetto, S.; Ferro, G.C.; Torre, R. Experimental evaluation of mechanical properties and machine process in fused deposition modelling printed polymeric elements. In Advances in Additive Manufacturing, Modelling Systems and 3D Prototyping; Di Nicolantonio, M., Rossi, E., Alexander, T., Eds.; Part of the Advances in Intelligent Systems and Computing Book Series; Springer: Cham, Switzerland, 2020; Volume 975, pp. 377–389. [Google Scholar]

- Torrado, A.R.; Shemelya, C.M.; English, J.D.; Lin, Y.; Wicker, R.B.; Roberson, D.A. Characterizing the effect of additives to ABS on the mechanical property anisotropy of specimens fabricated by material extrusion 3D printing. Addit. Manuf. 2015, 6, 16–29. [Google Scholar] [CrossRef]

- Oleksy, M.; Oliwa, R.; Bulanda, K.; Budzik, G.; Przeszłowski, Ł.; Magniszewski, M.; Paszkiewicz, A. Torsional strength tests of spline connections made of polymer materials (rapid communication). Polimery 2021, 66, 52–55. [Google Scholar] [CrossRef]

- Fischer, M.; Schöppner, V. Fatigue behavior of FDM parts manufactured with ultem 9085. JOM 2017, 69, 563–568. [Google Scholar] [CrossRef]

- Pisula, J.M.; Budzik, G.; Przeszlowski, L. An analysis of the surface geometric structure and geometric accuracy of cylindrical gear teeth manufactured with the direct metal laser sintering (DMLS) method. Strojniski Vestnik J. Mech. Eng. 2019, 65, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Turek, P. Automating the process of designing and manufacturing polymeric models of anatomical structures of mandible with industry 4.0 convention. Polimery 2019, 64, 522–529. [Google Scholar] [CrossRef]

- Habrat, W.; Zak, M.; Krolczyk, J.; Turek, P. Comparison of geometrical accuracy of a component manufactured using additive and conventional methods. In Advances in Manufacturing; Springer: Cham, Switzerland, 2018; pp. 765–776. [Google Scholar]

- Józwik, J. Analysis of the effect of trochoidal milling on the surface roughness of aluminium alloys after milling. Manuf. Technol. 2019, 19, 772–779. [Google Scholar] [CrossRef]

- Nieslony, P.; Krolczyk, G.M.; Wojciechowski, S.; Chudy, R.; Zak, K.; Maruda, R.W. Surface quality and topographic inspection of variable compliance part after precise turning. Appl. Surf. Sci. 2018, 434, 91–101. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Comparison of results of surface texture measurement obtained with stylus methods and optical methods. Metrol. Meas. Syst. 2018, 25, 589–602. [Google Scholar]

- Kozior, T.; Adamczak, S. Amplitude surface texture parameters of models manufactured by FDM technology. In The International Symposium for Production Research; Springer: Cham, Switzerland, 2018; pp. 208–217. [Google Scholar]

- Turek, P.; Budzik, G.; Sęp, J.; Oleksy, M.; Józwik, J.; Przeszłowski, Ł.; Paszkiewicz, A.; Kochmański, Ł.; Żelechowski, D. An analysis of the casting polymer mold wear manufactured using polyjet method based on the measurement of the surface topography. Polymers 2020, 12, 3029. [Google Scholar] [CrossRef]

- Kozior, T.; Bochnia, J. The Influence of printing orientation on surface texture parameters in powder bed fusion technology with 316L steel. Micromachines 2020, 11, 639. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Hamoud, M. Surface roughness justification in additive manufacturing. In Proceedings of the International Conference on Applied Mechanics and Mechanical Engineering, Military Technical College, Cairo, Egypt, 3–5 April 2018; pp. 1–11. [Google Scholar]

- Shim, J.S.; Kim, J.-E.; Jeong, S.H.; Choi, Y.J.; Ryu, J.J. Printing accuracy, mechanical properties, surface characteristics, and microbial adhesion of 3D-printed resins with various printing orientations. J. Prosthet. Dent. 2019, 124. [Google Scholar] [CrossRef]

- Fox, J.C.; Moylan, S.P.; Lane, B.M. Effect of process parameters on the surface roughness of overhanging structures in laser powder bed fusion additive manufacturing. Procedia CIRP 2016, 45, 131–134. [Google Scholar] [CrossRef] [Green Version]

- Jamshidinia, M.; Kovacevic, R. The influence of heat accumulation on the surface roughness in powder-bed additive manufacturing. Surf. Topogr. Metrol. Prop. 2015, 3. [Google Scholar] [CrossRef]

- Kumar, K.; Kumar, G.S. An experimental and theoretical investigation of surface roughness of poly-jet printed parts: This paper explains how local surface orientation affects surface roughness in a poly-jet process. Virtual Phys. Prototyp. 2015, 10, 23–34. [Google Scholar] [CrossRef]

- Vorburger, T.V.; Rhee, H.G.; Renegar, T.B.; Song, J.F.; Zheng, A. Comparison of optical and stylus methods for measurement of surface texture. Int. J. Adv. Manuf. Technol. 2007, 33, 110–118. [Google Scholar] [CrossRef]

- Leach, R. (Ed.) Optical Measurement of Surface Topography; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Launhardt, M.; Wörz, A.; Loderer, A.; Laumer, T.; Drummer, D.; Hausotte, T.; Schmidt, M. Detecting surface roughness on SLS parts with various measuring techniques. Polym. Test. 2016, 53, 217–226. [Google Scholar] [CrossRef]

- Bezak, T.; Kusy, M.; Elias, M.; Kopcek, M.; Kebisek, M.; Spendla, L. Identification of surface topography scanned by laser Scanning confocal microscope. Appl. Mech. Mater. 2014, 693, 329–334. [Google Scholar] [CrossRef]

- Fu, S.; Cheng, F.; Tjahjowidodo, T.; Zhou, Y.; Butler, D. A non-contact measuring system for in-situ surface characterization based on laser confocal microscopy. Sensors 2018, 18, 2657. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y.; Zhang, X.; Wang, S.; Li, Q.; Qin, H.; Li, B. Similarity evaluation of topography measurement results by different optical metrology technologies for additive manufactured parts. Opt. Lasers Eng. 2020, 126. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Zheng, Y.; Suresh, V.; Wang, S.; Li, Q.; Li, B.; Qin, H. Correlation approach for quality assurance of additive manufactured parts based on optical metrology. J. Manuf. Process. 2020, 53, 310–317. [Google Scholar] [CrossRef]

- Kapłonek, W.; Nadolny, K.; Królczyk, G.M. The use of focus-variation microscopy for the assessment of active surfaces of a new generation of coated abrasive tools. Meas. Sci. Rev. 2016, 16, 42–53. [Google Scholar] [CrossRef] [Green Version]

- Bazan, A.; Kawalec, A.; Rydzak, T.; Kubik, P.; Olko, A. Determination of selected texture features on a single-layer grindingwheelactive surface for tracking their changes as a result of wear. Materials 2021, 14, 6. [Google Scholar] [CrossRef]

- Leksycki, K.; Królczyk, J.B. Comparative assessment of the surface topography for different optical profilometry techniques after dry turning of Ti6Al4V titanium alloy. Measurement 2021, 169. [Google Scholar] [CrossRef]

- Gomez, C.; Su, R.; Thompson, A.; DiSciacca, J.; Lawes, S.; Leach, R.K. Optimization of surface measurement for metal additive manufacturing using coherence scanning interferometry. Opt. Eng. 2017, 56. [Google Scholar] [CrossRef] [Green Version]

- ISO. ISO 53:1998 Cylindrical Gears for General and Heavy Engineering—Standard Basic Rack Tooth Profile; ISO: Geneva, Switzerland, 1998. [Google Scholar]

- ABS-M30 Data Sheet. Available online: https://www.stratasys.com/materials/search/abs-m30 (accessed on 7 March 2021).

- ULTEM™ 9085 Product Sheet. Available online: https://www.stratasys.com/materials/search/ultem9085 (accessed on 7 March 2021).

- PEEK Technical Data [3D4Makers]. Available online: http://support.3dgence.com/materialy.html (accessed on 7 March 2021).

- Max Continuous Service Temperature. Hardness Shore, D. Available online: https://omnexus.specialchem.com/polymer-properties/properties/ (accessed on 7 March 2021).

- Stratasys F123 Series Printers. Available online: https://www.stratasys.com/3d-printers/f123 (accessed on 7 March 2021).

- Fortus 380mc and Fortus 450mc. Available online: https://www.stratasys.com/3d-printers/fortus-380mc-450mc (accessed on 7 March 2021).

- Industry F340. Available online: https://3dgence.com/3d-printers/industry-f340/ (accessed on 7 March 2021).

- P40 Klingelnberg Precision Measuring Center. Available online: https://www.klingelnberg.com/en/business-divisions/precision-measuring-centers/precision-measuring-centers/detail-page/product/p-40/ (accessed on 7 March 2021).

- DIN. DIN 3962 1,2: 1978, Tolerances for Cylindrical Gear Teeth. Part 1: Tolerances for Deviations of Individual Parameters. Part 2: Tolerances for Tooth Trace Deviation; Deutsche Normen: Berlin, Germany, 1978. [Google Scholar]

- ISO. ISO 4288:2011 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- ISO. ISO 25178-2:2012 Geometrical Product Specifications (GPS). In Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- ISO. ISO 2039-1:2001 Plastics—Determination of Hardness—Part 1: Ball Indentation Method; ISO: Geneva, Switzerland, 2001. [Google Scholar]

- ISO. ISO 2039-2:2000 Plastics—Determination of Hardness—Part 2: Rockwell Hardness; ISO: Geneva, Switzerland, 2000. [Google Scholar]

- ISO. ISO 868:2003 Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness); ISO: Geneva, Switzerland, 2003. [Google Scholar]

| Parameter | Driving Gear | Driven Gear |

|---|---|---|

| Number of teeth | 17 | 21 |

| Pressure angle (deg) | 20.000 | |

| Module (mm) | 3.000 | |

| Profile shift coefficient | 0.000 | 0.000 |

| Dedendum coefficient of the basic rack profile | 1.250 | 1.250 |

| Root radius coefficient of the basic rack profile | 0.200 | 0.200 |

| Addendum coefficient of the basic rack profile | 1.000 | 1.000 |

| Centre distance (mm) | 57.000 | |

| Face width (mm) | 14.000 | 12.000 |

| Outside diameter (mm) | 57.000 | 69.000 |

| Base tangent length (no backlash) (mm) | ||

| Normal backlash (mm) | 0.188 | |

| Parameter/Material | ABS M-30 | ULTEM 9085 | PEEK (360–400) |

|---|---|---|---|

| Continuous operation temperature | up to 85 °C | up to 170 °C | up to 260 °C |

| Tensile Strength, Yield (ASTM D638) (ISO 527—PEEK) | 31 MPa | 77.1 MPa | 105 MPa |

| Modulus (Elastic) (ASTM D638) (ISO 527—PEEK) | 2.4 GPa | 2.54 GPa | 4.1 GPa |

| Flexural Strength (ASTM D790) (ISO 604—PEEK) | 60 MPa | 98.3 MPa | 130 MPa |

| IZOD Impact, notched (ASTM D256) (ISO 180/A—PEEK) | 101 J/m | 73.7 J/m | 5 kJ/m2 |

| Shore D Hardness (ASTM D2240) (ISO 868—PEEK) | 100 | 95–99 | 85–95 |

| HDT—Heat Distortion Temperature at 1.82 MPa (ASTM D648) (ISO 75A-f—PEEK) | 100 °C | 172.9 °C | 156 °C |

| Additive Manufacturing | FDM | FDM | FFF |

|---|---|---|---|

| Printer | Stratasys F170 | Fortus 450mc (Stratasys) | 3DGence Industry F340 |

| Material (brand name) | ABS M-30 ivory | ULTEM 9085 resin black | PEEK natural (360–400) |

| General type of material | ABS—Acrylonitrile Butadiene Styrene | PEI—Polyetherimide | PEEK—Polyetheretherketone |

| Processing temp. | 250 °C–260 °C | ca. 380 °C | ca. 410 °C |

| Fill material | ca. 100% | 100% | 80% |

| Layer thickness | 0.254 mm | 0.254 mm | 0.15 mm |

| Support material | QSR | ULTEM 9085 resin support | ESM-10 3DGence |

| Post-processing | Soluble | Breakaway | Soluble |

| Measuring Machine | Klingelnberg Gear Measuring Centre P40 |

|---|---|

| Probe System | K3D (M44) |

| Resolution | <0.01 μm |

| Probe | D = 1.5 mm |

| Length measurement uncertainty | according to VDI/VDE 2617 U1 = 1.8 + L/250 [μm] L—length in mm |

| Teeth to be checked (profile, lead) | 3 teeth (evenly around the gear circumference) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pisula, J.; Budzik, G.; Turek, P.; Cieplak, M. An Analysis of Polymer Gear Wear in a Spur Gear Train Made Using FDM and FFF Methods Based on Tooth Surface Topography Assessment. Polymers 2021, 13, 1649. https://doi.org/10.3390/polym13101649

Pisula J, Budzik G, Turek P, Cieplak M. An Analysis of Polymer Gear Wear in a Spur Gear Train Made Using FDM and FFF Methods Based on Tooth Surface Topography Assessment. Polymers. 2021; 13(10):1649. https://doi.org/10.3390/polym13101649

Chicago/Turabian StylePisula, Jadwiga, Grzegorz Budzik, Paweł Turek, and Mariusz Cieplak. 2021. "An Analysis of Polymer Gear Wear in a Spur Gear Train Made Using FDM and FFF Methods Based on Tooth Surface Topography Assessment" Polymers 13, no. 10: 1649. https://doi.org/10.3390/polym13101649