Viable Materials with a Giant Magnetocaloric Effect

Abstract

:1. Introduction

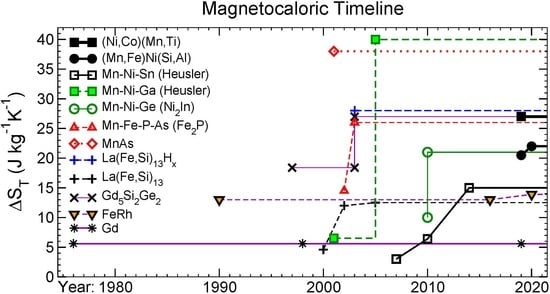

2. Materials with a Giant MCE

| Composition | ΔST | Tc (K) | ΔTS (K) | ΔTh (K) | Critical | Ref. | Year |

|---|---|---|---|---|---|---|---|

| Ni37.5Co12.5Mn35Ti15 | 27 | 290 | - | [30] | 2019 | ||

| Ni36.3Co13.7Mn35Ti15 | 18 | 260 | - | [30] | 2019 | ||

| Ni35Co15Mn35Ti15 | 5 | 180 | - | [30] | 2019 | ||

| Mn0.5Fe0.5NiSi0.95Al0.05 | 15.5 | 316.5 | - | [31] | 2019 | ||

| Mn0.5Fe0.5NiSi0.945Al0.055 | 19.5 | 287 | - | [31] | 2019 | ||

| Mn0.5Fe0.5NiSi0.94Al0.06 | 20.5 | 268 | - | [31] | 2019 | ||

| Mn0.5Fe0.5NiSi0.935Al0.065 | 22 | 243 | - | [31] | 2019 | ||

| Mn0.5Fe0.5NiSi0.93Al0.07 | 22 | 208 | - | [31] | 2019 | ||

| Mn0.5Fe0.5NiSi0.94Al0.06B0.05 | 22 | 283 | 25 1 | - | [31] | 2020 | |

| Ni44.5Mn37Fe6.7Sn11.8 | 5.6 | 293 | - | [80] | 2010 | ||

| Ni44.2Mn39.3Fe4.9Sn11.6 | 6.4 | 284 | - | [80] | 2010 | ||

| Ni44.4Mn44.1Sn11.5 | 10.6 | 260 | - | [80] | 2010 | ||

| Ni50.2Mn35.0In14.8 | 18 | 301 | 1.2 | 3.6 | In | [81] | 2016 |

| Ni49.6Mn35.6In14.8 | 7.5 | 268 | 1.6 | 7.9 | In | [81] | 2016 |

| Ni45.7Mn36.6Co4.2In13.5 | 10.5 | 289 | 3.0 | 10 | In | [82] | 2015 |

| Ni55.4Mn20Ga24.6 | 40 | 313 | 1.5 | 8 | Ga | [74] | 2005 |

| MnFeP0.45As0.55 | 14.5 | 300 | 1 1 | As 4 | [50] | 2002 | |

| MnAs | 38 | 315 | As 4 | [45] | 2001 | ||

| La0.7Ca0.3MnO3 | 5.7 | 260 | 2.3 | -0 | - | [83] | 2019 |

| La(Fe,Co,Al)13 | - | 0–400 | - | - | - | [84] | 1992 |

| LaFe11.4Si1.6 | 14 1 | 209 | - | [85] | 2000 | ||

| LaFe11.4Si1.6 | 14.3 | 208 | - | [86] | 2001 | ||

| LaFe11.4Si1.6 | 14.2 | 199 | - | [87] | 2009 | ||

| LaFe11.7Si1.3 | 25 | 188 | 4 | 2 | - | [88] | 2005 |

| LaFe11.2Co0.7Si1.1 | 12.5 | 274 | 2.4 | 2 | - | [88] | 2005 |

| LaFe11.12Co0.711Al1.17 | 4.6 | 279 | - | [85] | 2000 | ||

| La(Fe0.96 Co0.04)11.9 Si1.1 | 16.4 | 243 | - | [89] | 2005 | ||

| La(Fe0.88 Co0.12)13 H1.5 | 19 | 323 | 6.8 | 1 1 | H 5 | [52] | 2003 |

| La(Fe0.89 Co0.11)13 H1.3 | 24 | 291 | 6.9 | 1 1 | H 5 | [52] | 2003 |

| La(Fe0.9Co0.1)13 H1.1 | 28 | 287 | 7.1 | 1 1 | H 5 | [52] | 2003 |

| Fe49Rh51 3 | 313 | −12.9 | 8.5 | Rh 6 | [21] | 1990 | |

| Fe49Rh51 | 13 1 | 317 | −9.2 2 | 10 1 | Rh 6 | [24] | 2016 |

| Fe49Rh51 | 13.9 | Rh 6 | [23] | 2020 | |||

| Gd5Si2Ge2 | 18.4 | 262 | 4.9 | 5 | Gd,Ge | [28] | 1997 |

| Gd5Si2Ge2 | 15 | 277 | 5 1 | Gd,Ge | [63] | 2003 | |

| Gd5Si2Ge2 3 | 27 | 270 | 7 | Gd,Ge | [63] | 2003 | |

| Gd5Si4 | 4.2 | 346 | Gd | [90] | 2001 | ||

| Gd | 6 1 | 293 | 4 1 | −0 | Gd | [27] | 1976 |

| Gd | 5.6 | 294 | 5 1 | −0 | Gd | [38] | 1998 |

| Gd | 5.2 | 292 | 4.7 | −0 | Gd | [91] | 2019 |

3. Properties

3.1. Thermodynamic Relations

3.2. Correlated Physical Properties

3.2.1. Multicaloric Effect

3.2.2. Hysteresis

3.2.3. Aging

3.3. Materials Life Cycle and Recyclability

4. Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zarkevich, N.A. Electricity without Fuel. J. Energy Power Technol. 2020, 2, 14. [Google Scholar] [CrossRef] [Green Version]

- U.S. Department of Energy. 2020. Available online: https://www.energy.gov/ (accessed on 6 June 2020).

- CaloriCool. Caloric Materials Consortium. 2020. Available online: https://www.caloricool.org/ (accessed on 6 June 2020).

- Kitanovski, A. Energy Applications of Magnetocaloric Materials. Adv. Energy Mater. 2020, 10, 1903741. [Google Scholar] [CrossRef]

- Tishin, A.M.; Spichkin, Y.I. The Magnetocaloric Effect and Its Applications; Series in Condensed Matter Physics; Philadelphia: Institute of Physics Pub: Bristol, UK, 2003; Volume xi, 475p. [Google Scholar]

- Magnetocaloric Energy Conversion; Springer: New York, NY, USA, 2014.

- Mozharivskyj, Y. Magnetocaloric Effect and Magnetocaloric Materials. In Reference Module in Chemistry, Molecular Sciences and Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Gschneidner, K.A.; Pecharsky, V.K. Magnetic Refrigeration. In Rare Earths: Science, Technology & Applications iii; TMS: Beijing, China, 1996; Volume 3, pp. 209–221, ISBN 0873393635; 9780873393638. [Google Scholar]

- Gschneidner, K.A.; Pecharsky, V.K.; Pecharsky, A.O.; Zimm, C.B. Recent developments in magnetic refrigeration. Mater. Sci. Forum 1999, 315, 69–76. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Gschneidner, K.A. Magnetocaloric effect and magnetic refrigeration. J. Magn. Magn. Mater. 1999, 200, 44–56. [Google Scholar] [CrossRef]

- Tishin, A.M.; Gschneidner, K.A.; Pecharsky, V.K. Magnetocaloric effect and heat capacity in the phase-transition region. Phys. Rev. B 1999, 59, 503–511. [Google Scholar] [CrossRef]

- Gschneidner, K.A.; Pecharsky, V.K. Magnetocaloric materials. Annu. Rev. Mater. Sci. 2000, 30, 387–429. [Google Scholar] [CrossRef] [Green Version]

- Tassou, S.A.; Lewis, J.S.; Ge, Y.T.; Hadawey, A. A review of emerging technologies for food refrigeration applications. Appl. Therm. Eng. 2010, 30, 263–276. [Google Scholar] [CrossRef] [Green Version]

- Pomeranchuk, I.Y. K тeopии жидкoгo He-3. Sov. Phys. JETP (USSR) 1950, 20, 919. [Google Scholar]

- Pomeranchuk, I.Y. Sobranie Nauchnykh Trudov. V 3-kh T; Nauka: Moskva, Russia, 1972; Volume 1. [Google Scholar]

- Greco, A.; Aprea, C.; Maiorino, A.; Masselli, C. A review of the state of the art of solid-state caloric cooling processes at room-temperature before 2019. Int. J. Refrigeration 2019, 106, 66–88. [Google Scholar] [CrossRef]

- Klinar, K.; Kitanovski, A. Thermal control elements for caloric energy conversion. Renew. Sustain. Energy Rev. 2020, 118, 109571. [Google Scholar] [CrossRef]

- Tesla, N. Pyromagneto-Electric Generator. U.S. Patent No. 428,057, 13 May 1890. [Google Scholar]

- Zarkevich, N.A.; Johnson, D.D. Reliable thermodynamic estimators for screening caloric materials. J. Alloys Compd. 2019, 802, 712–722. [Google Scholar] [CrossRef] [Green Version]

- Ponomarev, B.K. Investigation of the antiferro-ferromagnetism transition in an FeRh alloy in a pulsed magnetic field up to 300 koe. Sov. Phys. JETP (USSR) 1973, 36, 105. [Google Scholar]

- Nikitin, S.; Skokov, K.P.; Koshkid’ko, Y.S.; Pastushenkov, Y.G.; Ivanova, T.I. The magnetocaloric effect in Fe49Rh51 compound. Phys. Lett. 1990, 6–7, 363–366. [Google Scholar] [CrossRef]

- Annaorazov, M.P.; Nikitin, S.A.; Tyurin, A.L.; Asatryan, K.A.; Dovletov, A.K. Anomalously high entropy change in FeRh alloy. J. Appl. Phys. 1996, 79, 1689–1695. [Google Scholar] [CrossRef]

- Sanchez-Valdes, C.F.; Gimaev, R.R.; Lopez-Cruz, M.; Llamazares, J.L.S.; Zverev, V.I.; Tishin, A.M.; Carvalho, A.M.G.; Aguiar, D.J.M.; Mudryk, Y.; Pecharsky, V.K. The effect of cooling rate on magnetothermal properties of Fe49Rh51. J. Magn. Magn. Mater. 2020, 498, 166130. [Google Scholar] [CrossRef]

- Chirkova, A.; Skokov, K.P.; Schultz, L.; Baranov, N.V.; Gutfleisch, O.; Woodcock, T.G. Giant adiabatic temperature change in FeRh alloys evidenced by direct measurements under cyclic conditions. Acta Mater. 2016, 106, 15–21. [Google Scholar] [CrossRef]

- Zakharov, A.I.; Kadomtseva, A.M.; Levitin, R.Z.; Ponyatovskii, E.G. Magnetic and magnetoelastic properties of a metamagnetic iron-rhodium alloy. Sov. Phys. JETP (USSR) 1964, 19, 1348. [Google Scholar]

- Shirane, G.; Nathans, R.; Chen, C.W. Magnetic moments and unpaired spin densities in the Fe-Rh alloys. Phys. Rev. 1964, 134, A1547–A1553. [Google Scholar] [CrossRef]

- Brown, G.V. Magnetic heat pumping near room temperature. J. Appl. Phys. 1976, 47, 3673–3680. [Google Scholar] [CrossRef] [Green Version]

- Pecharsky, V.K.; Gschneidner, J.K.A. Giant Magnetocaloric Effect in Gd5Si2Ge2. Phys. Rev. Lett. 1997, 78, 4494–4497. [Google Scholar] [CrossRef]

- Zarkevich, N.A.; Johnson, D.D.; Pecharsky, V.K. High-throughput search for caloric materials: The CaloriCool approach. J. Phys. D Appl. Phys. 2017, 51, 024002. [Google Scholar] [CrossRef] [Green Version]

- Bez, H.N.; Pathak, A.K.; Biswas, A.; Zarkevich, N.A.; Balema, V.; Mudryk, Y.; Johnson, D.D.; Pecharsky, V.K. Giant enhancement of the magnetocaloric response in Ni–Co–Mn–Ti by rapid solidification. Acta Mater. 2019, 173, 225–230. [Google Scholar]

- Biswas, A.; Pathak, A.K.; Zarkevich, N.A.; Liu, X.; Mudryk, Y.; Balema, V.; Johnson, D.D.; Pecharsky, V.K. Designed materials with the giant magnetocaloric effect near room temperature. Acta Mater. 2019, 180, 341–348. [Google Scholar] [CrossRef]

- Zarkevich, N.A.; Johnson, D.D. FeRh ground state and martensitic transformation. Phys. Rev. B 2018, 97, 014202. [Google Scholar] [CrossRef] [Green Version]

- Yibole, H.; Pathak, A.K.; Mudryk, Y.; Guillou, F.; Zarkevich, N.A.; Gupta, S.; Balema, V.; Pecharsky, V.K. Manipulating the stability of crystallographic and magnetic sub-lattices: A first-order magnetoelastic transformation in transition metal based Laves phase. Acta Mater. 2018, 154, 365–374. [Google Scholar] [CrossRef] [Green Version]

- Bez, H.N.; Biswas, A.; Pathak, A.K.; Mudryk, Y.; Zarkevich, N.A.; Balema, V.; Pecharsky, V.K. Highly Tunable, Inexpensive and Easily Fabricated Magnetocaloric Materials; Iowa State University Research Foundation: Ames, IA, USA, 2019; U.S. Patent Application No. 2019/0214169A1, 11 July 2019. [Google Scholar]

- Pathak, A.K.; Mudryk, Y.; Dolotko, O.; Pecharsky, V.K. Modified La-Fe-Si Magnetocaloric Alloys; Iowa State University Research Foundation: Ames, IA, USA, 2019; U.S. Patent Application No. US2019/027293A1, 5 September 2019. [Google Scholar]

- Gschneidner, K.A.; Pecharsky, V.K. Thirty years of near room temperature magnetic cooling: Where we are today and future prospects. Int. J. Refrig. 2008, 31, 945–961. [Google Scholar] [CrossRef] [Green Version]

- Dan’kov, S.Y.; Tishin, A.M.; Pecharsky, V.K.; Gschneidner, K.A. Experimental device for studying the magnetocaloric effect in pulse magnetic fields. Rev. Sci. Instrum. 1997, 68, 2432–2437. [Google Scholar] [CrossRef]

- Dan’kov, S.Y.; Tishin, A.M.; Pecharsky, V.K.; Gschneidner, K.A. Magnetic phase transitions and the magnetothermal properties of gadolinium. Phys. Rev. B 1998, 57, 3478–3490. [Google Scholar] [CrossRef]

- Dong, Q.Y.; Hou, K.Y.; Zhang, X.Q.; Su, L.; Wang, L.C.; Ke, Y.J.; Yan, H.T.; Cheng, Z.H. Giant reversible magnetocaloric effect in antiferromagnetic rare-earth cobaltite GdCoO3. J. Appl. Phys. 2020, 127, 033904. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Gschneidner, K.A.; Dan’kov, S.Y.; Tishin, A.M. Magnetocaloric properties of Gd3Al2. In Cryocoolers 10; Springer: Boston, MA, USA, 1999; pp. 639–645, ISBN: 030646120X; 030646090X. [Google Scholar]

- Pecharsky, V.K.; Gschneidner, K.A. Gd-Zn alloys as active magnetic regenerator materials for magnetic refrigeration. In Cryocoolers 10; Springer: Boston, MA, USA, 1999; pp. 629–637, ISBN: 030646120X; 030646090X. [Google Scholar]

- Liu, J.; Gong, Y.Y.; Xu, G.Z.; Peng, G.; Shah, I.A.; Hassan, N.; Xu, F. Realization of magnetostructural coupling by modifying structural transitions in MnNiSi-CoNiGe system with a wide Curie-temperature window. Sci. Rep. 2016, 6, 23386. [Google Scholar] [CrossRef]

- Samanta, T.; Dubenko, I.; Quetz, A.; Stadler, S.; Ali, N. Giant magnetocaloric effects near room temperature in Mn1−xCuxCoGe. Appl. Phys. Lett. 2012, 101, 242405. [Google Scholar] [CrossRef]

- Zhou, X.Z.; Li, W.; Kunkel, H.P.; Williams, G. A criterion for enhancing the giant magnetocaloric effect: (Ni-Mn-Ga)—A promising new system for magnetic refrigeration. J. Phys.-Condens. Matter 2004, 16, L39–L44. [Google Scholar] [CrossRef]

- Wada, H.; Tanabe, Y. Giant magnetocaloric effect of MnAs1−xSbx. Appl. Phys. Lett. 2001, 79, 3302–3304. [Google Scholar] [CrossRef]

- Wada, H.; Tanabe, Y. Giant magnetocaloric effect of MnAs1−xSbx in the vicinity of first-order magnetic transition. Phys. B-Condens. Matter 2003, 328, 114–116. [Google Scholar] [CrossRef]

- von Ranke, P.J.; de Oliveira, N.A.; Gama, S. Theoretical investigations on giant magnetocaloric effect in MnAs1−xSbx. Phys. Lett. A 2004, 320, 302–306. [Google Scholar] [CrossRef]

- von Ranke, P.J.; de Campos, A.; Caron, L.; Coelho, A.A.; Gama, S.; de Oliveira, N.A. Calculation of the giant magnetocaloric effect in the MnFeP0.45As0.55 compound. Phys. Rev. B 2004, 70, 094410. [Google Scholar] [CrossRef]

- Xiao, S.F.; Chen, Y.G.; Tu, M.J. Introduction to a new kind of magnetic refrigerating material with giant magnetocaloric effect—Mn-Fe-P-As compounds. Rare Met. Mater. Eng. 2004, 33, 23–28. [Google Scholar]

- Zhang, Y.Q.; Zhang, Z.D. Giant magnetoresistance and magnetocaloric effects of the Mn1.82V0.18Sb compound. J. Alloys Compd. 2004, 365, 35–38. [Google Scholar] [CrossRef]

- Kartashev, A.V.; Flerov, I.N.; Gorev, M.V.; Mikhashenok, N.V. Effect of Isovalent Cation Substitution on the Thermal, Caloric, and Magnetocaloric Properties of the (La1−yEuy)0.7Pb0.3MnO3 Manganites. Phys. Solid State 2019, 61, 62–68. [Google Scholar] [CrossRef]

- Fujita, A.; Fujieda, S.; Hasegawa, Y.; Fukamichi, K. Itinerant-electron metamagnetic transition and large magnetocaloric effects in La(FexSi1−x)13 compounds and their hydrides. Phys. Rev. B 2003, 67, 104416. [Google Scholar] [CrossRef] [Green Version]

- Fujieda, S.; Fujita, A.; Fukamichi, K. Large magnetocaloric effects in NaZn13-type La(FexSi1−x)13 compounds and their hydrides composed of icosahedral clusters. Sci. Technol. Adv. Mater. 2003, 4, 339–346. [Google Scholar] [CrossRef]

- Terwey, A.; Gruner, M.E.; Keune, W.; Landers, J.; Salamon, S.; Eggert, B.; Ollefs, K.; Brabander, V.; Radulov, I.; Skokov, K.; et al. Influence of hydrogenation on the vibrational density of states of magnetocaloric LaFe11.4Si1.6H1.6. Phys. Rev. B 2020, 101, 064415. [Google Scholar] [CrossRef] [Green Version]

- Debnath, J.C.; Zeng, R.; Kim, J.H.; Shamba, P.; Dou, S.X. Reduction of hysteresis loss in LaFe11.7Si1.3Hx hydrides with significant magnetocaloric effects. Appl. Phys. A 2012, 106, 245–250. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Gschneidner, K.A. Effect of alloying on the giant magnetocaloric effect of Gd5(Si2Ge2). J. Magn. Magn. Mater. 1997, 167, L179–L184. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Gschneidner, K.A. Tunable magnetic regenerator alloys with a giant magnetocaloric effect for magnetic refrigeration from ~20 to ~ 290 K. Appl. Phys. Lett. 1997, 70, 3299–3301. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Gschneidner, K.A. The giant magnetocaloric effect in Gd5(SixGe1−x)4 materials for magnetic refrigeration. Adv. Cryog. Eng. 1998, 43(Pts A and B), 1729–1736. [Google Scholar]

- Giguere, A.; Foldeaki, M.; Gopal, B.R.; Chahine, R.; Bose, T.K.; Frydman, A.; Barclay, J.A. Direct measurement of the “giant” adiabatic temperature change in Gd5Si2Ge2. Phys. Rev. Lett. 1999, 83, 2262–2265. [Google Scholar] [CrossRef]

- Gschneidner, K.A.; Pecharsky, A.O.; Pecharsky, V.K.; Lograsso, T.A.; Schlagel, D.L. Production of the giant magnetocaloric effect Gd5(SixGe1−x)4 magnetic refrigerant materials from commercial gadolinium metal. In Rare Earths and Actinides: Science, Technology and Applications IV: Proceedings of a Symposium Held During the 2000 TMS Annual Meeting in Nashville, Nashville, TN, USA, 12–16 March 2000; TMS: Beijing, China, 2000; pp. 63–72, ISBN: 0873394704. [Google Scholar]

- Choe, W.; Pecharsky, V.K.; Pecharsky, A.O.; Gschneidner, K.A.; Young, V.G.; Miller, G.J. Making and breaking covalent bonds across the magnetic transition in the giant magnetocaloric material Gd5(Si2Ge2). Phys. Rev. Lett. 2000, 84, 4617–4620. [Google Scholar] [CrossRef] [Green Version]

- Pecharsky, A.O.; Gschneidner, K.A.; Pecharsky, V.K. The giant magnetocaloric effect between 190 and 300 K in the Gd5SixGe4−x alloys for 1.4 <= x <= 2.2. J. Magn. Magn. Mater. 2003, 267, 60–68. [Google Scholar]

- Pecharsky, A.O.; Gschneidner, K.A., Jr.; Pecharsky, V.K. The giant magnetocaloric effect of optimally prepared Gd5Si2Ge2. J. Appl. Phys. 2003, 93, 4722–4728. [Google Scholar] [CrossRef]

- Casanova, F.; Batlle, X.; Labarta, A.; Marcos, J.; Manosa, L.; Planes, A. Change in entropy at a first-order magnetoelastic phase transition: Case study of Gd5(SixGe1−x)4 giant magnetocaloric alloys. J. Appl. Phys. 2003, 93, 8313–8315. [Google Scholar] [CrossRef] [Green Version]

- Lewis, L.H.; Yu, M.H.; Gambino, R.J. Simple enhancement of the magnetocaloric effect in giant magnetocaloric materials. Appl. Phys. Lett. 2003, 83, 515–517. [Google Scholar] [CrossRef]

- Wu, W.; Zhao, P.; Jiang, Z.L.; Li, Y.H.; Zhu, X.D.; Zhou, T.D. Influence of Gd purity on giant magnetocaloric effect of Gd-Si-Ge alloys. Rare Met. Mater. Eng. 2003, 32, 962–964. [Google Scholar]

- Casanova, F.; Labarta, A.; Batlle, X.; Perez-Reche, F.J.; Vives, E.; Manosa, L.; Planes, A. Direct observation of the magnetic-field-induced entropy change in Gd5(SixGe1−x)4 giant magnetocaloric alloys. Appl. Phys. Lett. 2005, 86, 262504. [Google Scholar] [CrossRef]

- Wu, W.; Tsokol, A.O.; Gschneidner, K.A.; Sampaio, J.A. Influence of oxygen on the giant magnetocaloric effect of Gd5Si1.95Ge2.05. J. Alloys Compd. 2005, 403, 118–123. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Holm, A.P.; Gschneidner, K.A.; Rink, R. Massive magnetic-field-induced structural transformation in Gd5Ge4 and the nature of the giant magnetocaloric effect. Phys. Rev. Lett. 2003, 91, 197204. [Google Scholar] [CrossRef]

- Magen, C.; Arnold, Z.; Morellon, L.; Skorokhod, Y.; Algarabel, P.A.; Ibarra, M.R.; Kamarad, J. Pressure-induced three-dimensional ferromagnetic correlations in the giant magnetocaloric compound Gd5Ge4. Phys. Rev. Lett. 2003, 91, 207202. [Google Scholar] [CrossRef]

- Ryan, D.H.; Wang, H.B.; Altounian, Z. Sn-119 Mossbauer study of the giant magnetocaloric compound: Gd5Sn4. In Hyperfine Interactions (C): Proceedings of the International Conference on the Applications of the Mössbauer Effect (ICAME 2001); Kluwer: Oxford, UK, 2002; Volume 5, pp. 217–220. [Google Scholar]

- Ryan, D.H.; Elouneg-Jamroz, M.; van Lierop, J.; Altounian, Z.; Wang, H.B. Field and temperature induced magnetic transition in Gd5Sn4: A giant magnetocaloric material. Phys. Rev. Lett. 2003, 90, 117202. [Google Scholar] [CrossRef] [Green Version]

- Morellon, L.; Arnold, Z.; Magen, C.; Ritter, C.; Prokhnenko, O.; Skorokhod, Y.; Algarabel, P.A.; Ibarra, M.R.; Kamarad, J. Pressure enhancement of the giant magnetocaloric effect in Tb5Si2Ge2. Phys. Rev. Lett. 2004, 93, 137201. [Google Scholar] [CrossRef]

- Pasquale, M.; Sasso, C.P.; Lewis, L.H.; Giudici, L.; Lograsso, T.; Schlagel, D. Magnetostructural transition and magnetocaloric effect in Ni55Mn20Ga25 single crystals. Phys. Rev. B 2005, 72, 094435. [Google Scholar] [CrossRef] [Green Version]

- Wada, H.; Asano, T. Effect of heat treatment on giant magnetocaloric properties of Mn1+δAs1−x Sbx. J. Magn. Magn. Mater. 2005, 290, 703–705. [Google Scholar] [CrossRef]

- Abramovich, A.I.; Michurin, A.V.; Gorbenko, O.Y.; Kaul’, A.R. Giant magnetocaloric effect near the Curie temperature in the Sm0.6Sr0.4MnO3 manganite. Phys. Solid State 2001, 43, 715–717. [Google Scholar] [CrossRef]

- Yamada, H.; Goto, T. Itinerant-electron metamagnetism and giant magnetocaloric effect. Phys. Rev. B 2003, 68, 184417. [Google Scholar] [CrossRef]

- Yamada, H.; Goto, T. Giant magnetocaloric effect in itinerant-electron metamagnets. Phys. B-Condens. Matter 2004, 346, 104–108. [Google Scholar] [CrossRef]

- de Oliveira, I.G.; von Ranke, P.J.; El Massalami, M.; Chaves, C.M. Giant magnetocaloric effect in tetragonal HoNi2B2C. Phys. Rev. B 2005, 72, 174420. [Google Scholar] [CrossRef]

- Yan, J.L.; Li, Z.Z.; Chen, X.; Zhou, K.W.; Shen, S.X.; Zhou, H.B. Martensitic transition and magnetocaloric properties in Ni45Mn44−xFexSn11 alloys. J. Alloys Compd. 2010, 506, 516–519. [Google Scholar] [CrossRef]

- Gottschall, T.; Skokov, K.P.; Burriel, R.; Gutfleisch, O. On the S(T) diagram of magnetocaloric materials with first-order transition: Kinetic and cyclic effects of Heusler alloys. Acta Mater. 2016, 107, 1–8. [Google Scholar] [CrossRef]

- Gottschall, T.; Skokov, K.P.; Frincu, B.; Gutfleisch, O. Large reversible magnetocaloric effect in Ni-Mn-In-Co. Appl. Phys. Lett. 2015, 106, 021901. [Google Scholar] [CrossRef]

- Gottschall, T.; Skokov, K.P.; Fries, M.; Taubel, A.; Radulov, I.; Scheibel, F.; Benke, D.; Riegg, S.; Gutfleisch, O. Making a Cool Choice: The Materials Library of Magnetic Refrigeration. Adv. Energy Mater. 2019, 9, 1901322. [Google Scholar] [CrossRef] [Green Version]

- Medvedeva, I.V.; Ganin, A.A.; Shcherbakova, Y.V.; Yermolenko, A.S.; Bersenev, Y.S. Magnetic phase transitions in the system La(Fe,Co,Ai)13 at high pressures. J. Alloys Compd. 1992, 178, 403–412. [Google Scholar] [CrossRef]

- Feng-Xia, H.; Bao-Gen, S.; Ji-Rong, S.; Xi-Xiang, Z. Great magnetic entropy change in La(Fe, M )13 (M=Si, Al) with Co doping. Chin. Phys. 2000, 9, 550–553. [Google Scholar] [CrossRef]

- Hu, F.X.; Shen, B.G.; Sun, J.R.; Cheng, Z.H.; Rao, G.H.; Zhang, X.X. Influence of negative lattice expansion and metamagnetic transition on magnetic entropy change in the compound LaFe11.4Si1.6. Appl. Phys. Lett. 2001, 78, 3675–3677. [Google Scholar] [CrossRef]

- Shen, B.G.; Sun, J.R.; Hu, F.X.; Zhang, H.W.; Cheng, Z.H. Recent Progress in Exploring Magnetocaloric Materials. Adv. Mater. 2009, 21, 4545–4564. [Google Scholar] [CrossRef] [Green Version]

- Ilyn, M.; Tishin, A.M.; Hu, F.; Gao, J.; Sun, J.R.; Shen, B.G. Magnetocaloric properties of the LaFe11.7Si1.3 and LaFe11.2Co0.7Si1.1 systems. J. Magn. Magn. Mater. 2005, 290, 712–714. [Google Scholar] [CrossRef]

- Hu, F.X.; Gao, J.; Qian, X.L.; Ilyn, M.; Tishin, A.M.; Sun, J.R.; Shen, B.G. Magnetocaloric effect in itinerant electron metamagnetic systems La(Fe1−xCox)11.9Si1.1. J. Appl. Phys. 2005, 97, 10M303. [Google Scholar] [CrossRef] [Green Version]

- Spichkin, Y.I.; Pecharsky, V.K.; Gschneidner, K.A. Preparation, crystal structure, magnetic and magnetothermal properties of (GdxR5−x)Si4, where R=Pr and Tb, alloys. J. Appl. Phys. 2001, 89, 1738–1745. [Google Scholar] [CrossRef]

- Gottschall, T.; Kuz’min, M.D.; Skokov, K.P.; Skourski, Y.; Fries, M.; Gutfleisch, O.; Zavareh, M.G.; Schlagel, D.L.; Mudryk, Y.; Pecharsky, V.; et al. Magnetocaloric effect of gadolinium in high magnetic fields. Phys. Rev. B 2019, 99, 134429. [Google Scholar] [CrossRef] [Green Version]

- Nayak, A.K.; Suresh, K.G.; Nigam, A.K. Giant inverse magnetocaloric effect near room temperature in Co substituted NiMnSb Heusler alloys. J. Phys. D-Appl. Phys. 2009, 42, 035009. [Google Scholar] [CrossRef] [Green Version]

- Entel, P.; Sokolovskiy, V.V.; Buchelnikov, V.D.; Ogura, M.; Gruner, M.E.; Grunebohm, A.; Comtesse, D.; Akai, H. The metamagnetic behavior and giant inverse magnetocaloric effect in Ni-Co-Mn-(Ga, In, Sn) Heusler alloys. J. Magn. Magn. Mater. 2015, 385, 193–197. [Google Scholar] [CrossRef]

- Ren, J.; Li, H.W.; Feng, S.T.; Zhai, Q.J.; Fu, J.X.; Luo, Z.P.; Zheng, H.X. Giant magnetocaloric effect in a Heusler Mn50Ni40In10 unidirectional crystal. Intermetallics 2015, 65, 10–14. [Google Scholar] [CrossRef] [Green Version]

- Paramanik, T.; Das, I. Near room temperature giant magnetocaloric effect and giant negative magnetoresistance in Co, Ga substituted Ni-Mn-In Heusler alloy. J. Alloys Compd. 2016, 654, 399–403. [Google Scholar] [CrossRef]

- Quetz, A.; Koshkid’ko, Y.S.; Titov, I.; Rodionov, I.; Pandey, S.; Aryal, A.; Ibarra-Gaytan, P.J.; Prudnikov, V.; Granovsky, A.; Dubenko, I.; et al. Giant reversible inverse magnetocaloric effects in Ni50Mn35In15 Heusler alloys. J. Alloys Compd. 2016, 683, 139–142. [Google Scholar] [CrossRef] [Green Version]

- Pandey, S.; Quetz, A.; Aryal, A.; Dubenko, I.; Blinov, M.; Rodionov, I.; Prudnikov, V.; Mazumdar, D.; Granovsky, A.; Stadler, S.; et al. Giant field-induced adiabatic temperature changes in In-based off-stoichiometric Heusler alloys. J. Appl. Phys. 2017, 121, 133901. [Google Scholar] [CrossRef]

- Pandey, S.; Quetz, A.; Aryal, A.; Dubenko, I.; Mazumdar, D.; Stadler, S.; Ali, N. Large Inverse Magnetocaloric Effects and Giant Magnetoresistance in Ni-Mn-Cr-Sn Heusler Alloys. Magnetochemistry 2017, 3, 3. [Google Scholar] [CrossRef]

- Chabri, T.; Ghosh, A.; Nair, S.; Awasthi, A.M.; Venimadhav, A.; Nath, T.K. Effects of the thermal and magnetic paths on first order martensite transition of disordered Ni45Mn44Sn9In2 Heusler alloy exhibiting a giant magnetocaloric effect and magnetoresistance near room temperature. J. Phys. D-Appl. Phys. 2018, 51, 195001. [Google Scholar] [CrossRef]

- Sokolovskiy, V.; Miroshkina, O.; Zagrebin, M.; Buchelnikov, V. Prediction of giant magnetocaloric effect in Ni40Co10Mn36Al14 Heusler alloys: An insight from ab initio and Monte Carlo calculations. J. Appl. Phys. 2020, 127, 163901. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.S.; Wang, Q.B.; Li, S.P.; Ao, W.Q.; Li, J.Q. The martensitic transition and magnetocaloric properties of Ni51Mn49−xSnx. Phys. B-Condens. Matter 2013, 412, 74–78. [Google Scholar] [CrossRef]

- Krenke, T.; Duman, E.; Acet, M.; Moya, X.; Manosa, L.; Planes, A. Effect of Co and Fe on the inverse magnetocaloric properties of Ni-Mn-Sn. J. Appl. Phys. 2007, 102, 033903. [Google Scholar] [CrossRef] [Green Version]

- Pasquale, M.; Sasso, C.P.; Giudici, L.; Lograsso, T.; Schlagel, D. Field-driven structural phase transition and sign-switching magnetocaloric effect in Ni-Mn-Sn. Appl. Phys. Lett. 2007, 91, 131904. [Google Scholar] [CrossRef] [Green Version]

- Phejar, M.; Paul-Boncour, V.; Bessais, L. Structural and magnetic properties of magnetocaloric LaFe13–xSix compounds synthesized by high energy ball-milling. Intermetallics 2010, 18, 2301–2307. [Google Scholar] [CrossRef]

- Chen, Y.-F.; Wang, F.; Shen, B.-G.; Sun, J.-R.; Wang, G.-J.; Hu, F.-X.; Cheng, Z.-H.; Zhu, T. Effects of carbon on magnetic properties and magnetic entropy change of the LaFe11.5Si1.5 compound. J. Appl. Phys. 2003, 93, 6981–6983. [Google Scholar] [CrossRef]

- Taskaev, S.V.; Kuz’min, M.D.; Skokov, K.P.; Karpenkov, D.Y.; Pellenen, A.P.; Buchelnikov, V.D.; Gutfleisch, O. Giant induced anisotropy ruins the magnetocaloric effect in gadolinium. J. Magn. Magn. Mater. 2013, 331, 33–36. [Google Scholar] [CrossRef]

- Amaral, J.S.; Amaral, V.S. Disorder effects in giant magnetocaloric materials. Phys. Status Solidi A-Appl. Mater. Sci. 2014, 211, 971–974. [Google Scholar] [CrossRef]

- Niknia, I.; Trevizoli, P.V.; Christiaanse, T.V.; Govindappa, P.; Teyber, R.; Rowe, A. Material screening metrics and optimal performance of an active magnetic regenerator. J. Appl. Phys. 2017, 121, 064902. [Google Scholar] [CrossRef]

- Kavita, S.; Anusha, G.; Bhatt, P.; Suresh, V.; Vijay, R.; Sethupathi, K.; Gopalan, R. On the giant magnetocaloric and mechanical properties of Mn-Fe-P-Si-Ge alloy. J. Alloys Compd. 2020, 817, 153232. [Google Scholar] [CrossRef]

- Jiang, W.H.; Mo, Z.J.; Luo, J.W.; Zheng, Z.X.; Lu, Q.J.; Liu, G.D.; Shen, J.; Li, L. Giant low-field magnetocaloric effect in EuTi1−xNbxO3 (x = 0.05, 0.1, 0.15, and 0.2) compounds. Chin. Phys. B 2020, 29, 037502. [Google Scholar] [CrossRef]

- Hanggai, W.; Tegus, O.; Yibole, H.; Guillou, F. Structural and magnetic phase diagrams of MnFe0.6Ni0.4(Si,Ge) alloys and their giant magnetocaloric effect probed by heat capacity measurements. J. Magn. Magn. Mater. 2020, 494, 165785. [Google Scholar] [CrossRef]

- Zhang, Y.K.; Guo, D.; Xu, H.; Ren, Z.M.; Wilde, G. Giant refrigerant capacity in equi-atomic HoErGdCuNi amorphous ribbons. J. Alloys Compd. 2019, 792, 180–184. [Google Scholar] [CrossRef]

- Zhang, W.; Mo, Z.J.; Jiang, W.H.; Hao, Z.H.; Luo, J.W.; Cheng, R.J.; Liu, G.D.; Li, L.; Shen, J. Giant low-field magnetic refrigeration in EuTi1−xAlxO3 (x = 0.05, 0.1 and 0.15) compounds. J. Magn. Magn. Mater. 2019, 492, 165684. [Google Scholar] [CrossRef]

- Zhang, W.; Mo, Z.J.; Hao, Z.H.; Shen, J.; Luo, J.W.; Chang, R.J.; Li, L. Fe doping effect on EuTiO3: The magnetic properties and giant magnetocaloric effect. Int. J. Appl. Ceram. Technol. 2019, 16, 1606–1611. [Google Scholar] [CrossRef]

- Zhang, K.; Tan, C.L.; Zhao, W.B.; Guo, E.J.; Tian, X.H. Computation-Guided Design of Ni-Mn-Sn Ferromagnetic Shape Memory Alloy with Giant Magnetocaloric Effect and Excellent Mechanical Properties and High Working Temperature via Multielement Doping. ACS Appl. Mater. Interfaces 2019, 11, 34827–34840. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.L.; Nie, Y.G.; Shi, H.F.; Ye, E.J.; Han, Z.D.; Wang, D.H. Tuning magnetostructural transition and the associated giant magnetocaloric effect via thermal treatment in MnCoGe-based alloys. J. Magn. Magn. Mater. 2019, 469, 437–442. [Google Scholar] [CrossRef]

- Wu, Y.D.; Chen, H.; Hua, J.Y.; Qin, Y.L.; Ma, X.H.; Wei, Y.Y.; Zi, Z.F. Giant reversible magnetocaloric effect in orthorhombic GdScO3. Ceram. Int. 2019, 45, 13094–13098. [Google Scholar] [CrossRef]

- Wada, H.; Fukuda, K.; Ohnishi, T.; Soejima, K.; Otsubo, K.; Yamashita, K. Thermal conductivity of giant magnetocaloric Mn compounds. J. Alloys Compd. 2019, 785, 445–451. [Google Scholar] [CrossRef]

- Mo, Z.J.; Jiang, W.H.; Zhao, Y.; Hao, Z.H.; Zheng, Z.X.; Zhang, W.; Li, L.; Shen, J. Low-field induced giant magnetocaloric effect in EuTi1−xNixO3 (x = 0.05, 0.1) compounds. J. Magn. Magn. Mater. 2019, 477, 258–263. [Google Scholar] [CrossRef]

- Lloveras, P.; Samanta, T.; Barrio, M.; Dubenko, I.; Ali, N.; Tamarit, J.L.; Stadler, S. Giant reversible barocaloric response of (MnNiSi)1−x(FeCoGe)x (x = 0.39, 0.40, 0.41). APL Mater. 2019, 7, 061106. [Google Scholar]

- Liu, J.; Gong, Y.Y.; You, Y.R.; You, X.M.; Huang, B.W.; Miao, X.F.; Xu, G.Z.; Xu, F.; Bruck, E. Giant reversible magnetocaloric effect in MnNiGe-based materials: Minimizing thermal hysteresis via crystallographic compatibility modulation. Acta Mater. 2019, 174, 450–458. [Google Scholar] [CrossRef]

- Li, Z.B.; Dong, S.Y.; Li, Z.Z.; Yang, B.; Liu, F.; Sanchez-Valdes, C.F.; Llamazares, J.L.S.; Zhang, Y.D.; Esling, C.; Zhao, X.; et al. Giant low-field magnetocaloric effect in Si alloyed Ni-Co-Mn-In alloys. Scr. Mater. 2019, 159, 113–118. [Google Scholar] [CrossRef]

- Koshkid’ko, Y.S.; Dilmieva, E.T.; Cwik, J.; Rogacki, K.; Kowalska, D.; Kamantsev, A.P.; Koledov, V.V.; Mashirov, A.V.; Shavrov, V.G.; Valkov, V.I.; et al. Giant reversible adiabatic temperature change and isothermal heat transfer of MnAs single crystals studied by direct method in high magnetic fields. J. Alloys Compd. 2019, 798, 810–819. [Google Scholar] [CrossRef]

- Jia, J.H.; Ke, Y.J.; Zhang, X.X.; Wang, J.F.; Su, L.; Wu, Y.D.; Xia, Z.C. Giant magnetocaloric effect in the antiferromagnet GdScO3 single crystal. J. Alloys Compd. 2019, 803, 992–997. [Google Scholar] [CrossRef]

- Hussain, R.; Cugini, F.; Baldini, S.; Porcari, G.; Amade, N.S.; Miao, X.F.; van Dijk, N.H.; Bruck, E.; Solzi, M.; De Renzi, R.; et al. Ubiquitous first-order transitions and site-selective vanishing of the magnetic moment in giant magnetocaloric MnFeSiP alloys detected by Mn-55 NMR. Phys. Rev. B 2019, 100, 104439. [Google Scholar] [CrossRef] [Green Version]

- Hu, S.Y.; Miao, X.F.; Liu, J.; Ou, Z.Q.; Cong, M.Q.; Haschuluu, O.; Gong, Y.Y.; Qian, F.J.; You, Y.R.; Zhang, Y.J.; et al. Small hysteresis and giant magnetocaloric effect in Nb-substituted (Mn,Fe)2(P,Si) alloys. Intermetallics 2019, 114, 106602. [Google Scholar] [CrossRef]

- Bouhani, H.; Endichi, A.; Zaari, H.; Benyoussef, A.; Hamedoun, M.; Balli, M.; El Kenz, A.; Mounkachi, O. On the origin of the giant magnetocaloric effect in HoMn2O5 single crystals: First principles study and Monte Carlo simulations. Mater. Chem. Phys. 2019, 231, 366–371. [Google Scholar] [CrossRef]

- Beckmann, C.; Ehrens, J.; Schnack, J. Rotational magnetocaloric effect of anisotropic giant-spin molecular magnets. J. Magn. Magn. Mater. 2019, 482, 113–119. [Google Scholar] [CrossRef] [Green Version]

- ul Hassan, N.; Shah, I.A.; Liu, J.; Xu, G.Z.; Gong, Y.Y.; Miao, X.F.; Xu, F. Magnetostructural Coupling and Giant Magnetocaloric Effect in Off-Stoichiometric MnCoGe Alloys. J. Supercond. Nov. Magn. 2018, 31, 3809–3815. [Google Scholar] [CrossRef]

- Polishchuk, D.M.; Tykhonenko-Polishchuk, Y.O.; Holmgren, E.; Kravets, A.F.; Tovstolytkin, A.I.; Korenivski, V. Giant magnetocaloric effect driven by indirect exchange in magnetic multilayers. Phys. Rev. Mater. 2018, 2, 114402. [Google Scholar] [CrossRef] [Green Version]

- Pankratov, N.; Mitsiuk, V.; Vetcher, A.; Krokhotin, A.; Govor, G.; Nikitin, S. Giant magnetocaloric effect in composites based on polymeric matrix and manganese arsenide. Mosc. Int. Symp. Magn. (MISM 2017) EPJ Web Conf. 2018, 185, 05010. [Google Scholar] [CrossRef]

- Moon, J.Y.; Kim, M.K.; Oh, D.G.; Kim, J.H.; Shin, H.J.; Choi, Y.J.; Lee, N. Anisotropic magnetic properties and giant rotating magnetocaloric effect in double-perovskite Tb2CoMnO6. Phys. Rev. B 2018, 98, 174424. [Google Scholar] [CrossRef] [Green Version]

- Mo, Z.J.; Sun, Q.L.; Shen, J.; Yang, M.; Li, Y.J.; Li, L.; Liu, G.D.; Tang, C.C.; Meng, F.B. Influences of La and Ce doping on giant magnetocaloric effect of EuTiO. Chin. Phys. B 2018, 27, 017501. [Google Scholar] [CrossRef]

- Mo, Z.J.; Sun, Q.L.; Shen, J.; Wang, C.H.; Meng, F.B.; Zhang, M.H.; Huo, Y.; Li, L.; Liu, G.D. A giant magnetocaloric effect in EuTi0.875Mn0.125O3 compound. J. Alloys Compd. 2018, 753, 1–5. [Google Scholar] [CrossRef]

- Mo, Z.J.; Sun, Q.L.; Han, S.; Zhao, Y.; Chen, X.; Li, L.; Liu, G.D.; Meng, F.B.; Shen, J. Effects of Mn-doping on the giant magnetocaloric effect of EuTiO3 compound. J. Magn. Magn. Mater. 2018, 456, 31–37. [Google Scholar] [CrossRef]

- Li, Z.Z.; Li, Z.B.; Yang, B.; Zhao, X.; Zuo, L. Giant low-field magnetocaloric effect in a textured Ni45.3Co5.1Mn36.1In13.5 alloy. Scr. Mater. 2018, 151, 61–65. [Google Scholar] [CrossRef]

- Landers, J.; Salamon, S.; Keune, W.; Gruner, M.E.; Krautz, M.; Zhao, J.; Hu, M.Y.; Toellner, T.S.; Alp, E.E.; Gutfleisch, O.; et al. Determining the vibrational entropy change in the giant magnetocaloric material LaFe11.6Si1.4 by nuclear resonant inelastic x-ray scattering. Phys. Rev. B 2018, 98, 024417. [Google Scholar]

- Ke, Y.J.; Zhang, X.Q.; Wang, J.F.; Cheng, Z.H. Giant magnetic entropy change in gadolinium orthoferrite near liquid hydrogen temperature. J. Alloys Compd. 2018, 739, 897–900. [Google Scholar] [CrossRef]

- Hu, F.X.; Shen, F.R.; Hao, J.Z.; Liu, Y.; Wang, J.; Sun, J.R.; Shen, B.G. Negative Thermal Expansion in the Materials with Giant Magnetocaloric Effect. Front. Chem. 2018, 6, 438. [Google Scholar] [CrossRef]

- Guillou, F.; Pathak, A.K.; Paudyal, D.; Mudryk, Y.; Wilhelm, F.; Rogalev, A.; Pecharsky, V.K. Non-hysteretic first-order phase transition with large latent heat and giant low-field magnetocaloric effect. Nat. Commun. 2018, 9, 1–9. [Google Scholar] [CrossRef]

- Gao, T.; Wu, M.; Qi, N.N.; Zhou, T.; Luo, X.J.; Liu, Y.S.; Xu, K.; Marchenkov, V.V.; Dong, H.L.; Chen, Z.Q.; et al. Giant low field magnetocaloric effect and magnetostructural coupling in MnCoGe1−xInx around room temperature. J. Alloys Compd. 2018, 753, 149–154. [Google Scholar] [CrossRef]

- Deepak, K.; Ramanujan, R.V. Near room temperature giant magnetocaloric effect in (MnNiSi)1−x(Fe2Ge)x alloys. J. Alloys Compd. 2018, 743, 494–505. [Google Scholar] [CrossRef]

- Das, M.; Roy, S.; Khan, N.; Mandal, P. Giant magnetocaloric effect in an exchange-frustrated GdCrTiO5 antiferromagnet. Phys. Rev. B 2018, 98, 104420. [Google Scholar] [CrossRef] [Green Version]

- Cong, D.Y.; Huang, L.; Hardy, V.; Bourgault, D.; Sun, X.M.; Nie, Z.H.; Wang, M.G.; Ren, Y.; Entel, P.; Wang, Y.D. Low-field-actuated giant magnetocaloric effect and excellent mechanical properties in a NiMn-based multiferroic alloy. Acta Mater. 2018, 146, 142–151. [Google Scholar] [CrossRef]

- Chen, J.H.; Saleheen, A.U.; Adams, P.W.; Young, D.P.; Ali, N.; Stadler, S. On entropy determination from magnetic and calorimetric experiments in conventional giant magnetocaloric materials. J. Appl. Phys. 2018, 123, 145101. [Google Scholar] [CrossRef]

- Chen, F.; Llamazares, J.L.S.; Sanchez-Valdes, C.F.; Mullner, P.; Shi, Y.G.; Tong, Y.X.; Li, L. High temperature martensitic transformation and giant magnetocaloric effect in Ni40Co10Mn41Sn9 melt-spun ribbons. J. Alloys Compd. 2018, 744, 493–501. [Google Scholar] [CrossRef]

- Born, N.O.; Caron, L.; Seeler, F.; Felser, C. Tunable giant magnetocaloric effect with very low hysteresis in Mn3CuN1−xCx. J. Alloys Compd. 2018, 749, 926–930. [Google Scholar] [CrossRef]

- Zhao, D.W.; Liu, J.; Chen, X.; Sun, W.; Li, Y.; Zhang, M.X.; Shao, Y.Y.; Zhang, H.; Yan, A.R. Giant caloric effect of low-hysteresis metamagnetic shape memory alloys with exceptional cyclic functionality. Acta Mater. 2017, 133, 217–223. [Google Scholar] [CrossRef]

- Yuan, Y.; Wu, Y.; Tong, X.; Zhang, H.; Wang, H.; Liu, X.J.; Ma, L.; Suo, H.L.; Lu, Z.P. Rare-earth high-entropy alloys with giant magnetocaloric effect. Acta Mater. 2017, 125, 481–489. [Google Scholar] [CrossRef] [Green Version]

- Thang, N.V.; van Dijk, N.H.; Bruck, E. Tuneable Giant Magnetocaloric Effect in (Mn,Fe)2(P,Si) Materials by Co-B and Ni-B Co-Doping. Materials 2017, 10, 14. [Google Scholar] [CrossRef]

- Sun, Q.L.; Mo, Z.J.; Shen, J.; Li, Y.J.; Li, L.; Zhang, J.K.; Liu, G.D.; Tang, C.C.; Meng, F.B. Observation of giant magnetocaloric effect under low magnetic fields in EuTi1−xCoxO3. Chin. Phys. B 2017, 26, 117501. [Google Scholar] [CrossRef]

- Ruan, M.Y.; Ouyang, Z.W.; Wang, Z.X.; Xia, Z.C.; Rao, G.H. Magnetization, ESR, and giant magnetocaloric effects in nanocrystals of Haldane-chain compound Gd2BaNiO5. Appl. Phys. Lett. 2017, 111, 122403. [Google Scholar] [CrossRef]

- Qu, Y.H.; Cong, D.Y.; Sun, X.M.; Nie, Z.H.; Gui, W.Y.; Li, R.G.; Ren, Y.; Wang, Y.D. Giant and reversible room-temperature magnetocaloric effect in Ti-doped Ni-Co-Mn-Sn magnetic shape memory alloys. Acta Mater. 2017, 134, 236–248. [Google Scholar] [CrossRef]

- Perez-Landazabal, J.I.; Recarte, V.; Sanchez-Alarcos, V.; Beato-Lopez, J.J.; Rodriguez-Velamazan, J.A.; Sanchez-Marcos, J.; Gomez-Polo, C.; Cesari, E. Giant direct and inverse magnetocaloric effect linked to the same forward martensitic transformation. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Moon, J.Y.; Kim, M.K.; Choi, Y.J.; Lee, N. Giant Anisotropic Magnetocaloric Effect in Double-perovskite Gd2CoMnO6 Single Crystals. Sci. Rep. 2017, 7, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Mo, Z.J.; Sun, Q.L.; Wang, C.H.; Wu, H.Z.; Li, L.; Meng, F.B.; Tang, C.C.; Zhao, Y.; Shen, J. Effects of Sr-doping on the giant magnetocaloric effect of EuTiO3. Ceram. Int. 2017, 43, 2083–2088. [Google Scholar] [CrossRef]

- Mo, Z.J.; Hao, Z.H.; Deng, J.Z.; Shen, J.; Li, L.; Wu, J.F.; Hu, F.X.; Sun, J.R.; Shen, B.G. Observation of giant magnetocaloric effect under low magnetic field in Eu1−xBaxTiO3. J. Alloys Compd. 2017, 694, 235–240. [Google Scholar] [CrossRef]

- Mahana, S.; Manju, U.; Topwal, D. Giant magnetocaloric effect in GdAlO3 and a comparative study with GdMnO3. J. Phys. D-Appl. Phys. 2017, 50, 035002. [Google Scholar] [CrossRef]

- Li, Y.W.; Zhang, H.; Tao, K.; Wang, Y.X.; Wu, M.L.; Long, Y. Giant magnetocaloric effect induced by reemergence of magnetostructural coupling in Si-doped Mn0.95CoGe compounds. Mater. Des. 2017, 114, 410–415. [Google Scholar] [CrossRef]

- Ho, T.A.; Lim, S.H.; Phan, T.L.; Yu, S.C. Universal curves in assessing the order of magnetic transition of La0.7−xPrxCa0.3MnO3 compounds exhibiting giant magnetocaloric effect. J. Alloys Compd. 2017, 692, 687–692. [Google Scholar] [CrossRef]

- de Oliveira, N.A. Giant rotating magnetocaloric effect in RNi5 single crystals. J. Phys. Chem. Solids 2017, 103, 13–15. [Google Scholar] [CrossRef]

- Das, M.; Roy, S.; Mandal, P. Giant reversible magnetocaloric effect in a multiferroic GdFeO3 single crystal. Phys. Rev. B 2017, 96, 174405. [Google Scholar] [CrossRef]

- Cervera, S.; Trassinelli, M.; Marangolo, M.; Carretero, C.; Garcia, V.; Hidki, S.; Jacquet, E.; Lamour, E.; Levy, A.; Mace, S.; et al. Modulating the phase transition temperature of giant magnetocaloric thin films by ion irradiation. Phys. Rev. Mater. 2017, 1, 065402. [Google Scholar] [CrossRef] [Green Version]

- Cai, Y.Q.; Jiao, Y.Y.; Cui, Q.; Cai, J.W.; Li, Y.; Wang, B.S.; Fernandez-Diaz, M.T.; McGuire, M.A.; Yan, J.Q.; Alonso, J.A.; et al. Giant reversible magnetocaloric effect in the pyrochlore Er2Mn2O7 due to a cooperative two-sublattice ferromagnetic order. Phys. Rev. Mater. 2017, 1, 064408. [Google Scholar] [CrossRef]

- Balli, M.; Fournier, P.; Jandl, S.; Mansouri, S.; Mukhin, A.; Ivanov, Y.V.; Balbashov, A.M. Comment on “Giant anisotropy of magnetocaloric effect in TbMnO3 single crystals”. Phys. Rev. B 2017, 96, 146401. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, Q.Y.; Wang, L.C.; Zhang, M.; Yan, H.T.; Sun, J.R.; Hu, F.X.; Shen, B.G. Giant low-field reversible magnetocaloric effect in HoCoGe compound. RSC Adv. 2016, 6, 106171–106176. [Google Scholar] [CrossRef]

- Zhang, X.X.; Qian, M.F.; Su, R.Z.; Geng, L. Giant room-temperature inverse and conventional magnetocaloric effects in Ni-Mn-In alloys. Mater. Lett. 2016, 163, 274–276. [Google Scholar] [CrossRef]

- Sharma, V.K.; Manekar, M.A.; Srivastava, H.; Roy, S.B. Giant magnetocaloric effect near room temperature in the off-stoichiometric Mn-Co-Ge alloy. J. Phys. D-Appl. Phys. 2016, 49, 50LT01. [Google Scholar] [CrossRef]

- Sarkar, S.K.; Sarita; Babu, P.D.; Biswas, A.; Siruguri, V.; Krishnan, M. Giant magnetocaloric effect from reverse martensitic transformation in Ni-Mn-Ga-Cu ferromagnetic shape memory alloys. J. Alloys Compd. 2016, 670, 281–288. [Google Scholar] [CrossRef] [Green Version]

- Roy, S.; Khan, N.; Mandal, P. Giant low-field magnetocaloric effect in single-crystalline EuTi0.85Nb0.15O3. APL Mater. 2016, 4, 026102. [Google Scholar] [CrossRef] [Green Version]

- Meng, L.J.; Xu, C.; Yuan, Y.; Qi, Y.; Zhou, S.Q.; Li, L.W. Magnetic properties and giant reversible magnetocaloric effect in GdCoC2. RSC Adv. 2016, 6, 74765–74768. [Google Scholar] [CrossRef] [Green Version]

- Madiligama, A.S.B.; Ari-Gur, P.; Shavrov, V.G.; Koledov, V.V.; Calder, S.; Mashirov, A.V.; Kamantsev, A.P.; Dilmieva, E.T.; Gonzalez-Legarreta, L.; Grande, B.H.; et al. Crystalline structure and magnetic behavior of the Ni41Mn39In12Co8 alloy demonstrating giant magnetocaloric effect. Smart Mater. Struct. 2016, 25, 085013. [Google Scholar] [CrossRef]

- Guillou, F.; Wilhelm, F.; Tegus, O.; Rogalev, A. Microscopic mechanism of the giant magnetocaloric effect in MnCoGe alloys probed by x-ray magnetic circular dichroism. Appl. Phys. Lett. 2016, 108, 122405. [Google Scholar] [CrossRef]

- Das, K.; Das, I. Giant enhancement of magnetocaloric effect at room temperature by the formation of nanoparticle of La0.48Ca0.52MnO3 compound. J. Appl. Phys. 2016, 119, 093903. [Google Scholar] [CrossRef]

- Chen, J.H.; Bruno, N.M.; Karaman, I.; Huang, Y.J.; Li, J.G.; Ross, J.H. Direct measure of giant magnetocaloric entropy contributions in Ni-Mn-In. Acta Mater. 2016, 105, 176–181. [Google Scholar] [CrossRef] [Green Version]

- Cao, Y.M.; Xiang, M.L.; Zhao, W.Y.; Wang, G.H.; Feng, Z.J.; Kang, B.J.; Stroppa, A.; Zhang, J.C.; Ren, W.; Cao, S.X. Magnetic phase transition and giant anisotropic magnetic entropy change in TbFeO3 single crystal. J. Appl. Phys. 2016, 119, 063904. [Google Scholar] [CrossRef]

- Brown, T.D.; Karaman, I.; Shamberger, P.J. Impact of cycle-hysteresis interactions on the performance of giant magnetocaloric effect refrigerants. Mater. Res. Express 2016, 3, 074001. [Google Scholar] [CrossRef] [Green Version]

- Bao, L.F.; Huang, W.D.; Ren, Y.J. Tuning Martensitic Phase Transition by Non-Magnetic Atom Vacancy in MnCoGe Alloys and Related Giant Magnetocaloric Effect. Chin. Phys. Lett. 2016, 33, 077502. [Google Scholar] [CrossRef]

- Balli, M.; Jandl, S.; Fournier, P.; Dimitrov, D.Z. Giant rotating magnetocaloric effect at low magnetic fields in multiferroic TbMn2O5 single crystals. Appl. Phys. Lett. 2016, 108, 102401. [Google Scholar] [CrossRef]

- Amaral, J.S.; Fortunato, N.M.; Amorim, C.; Goncalves, J.N.; Amaral, V.S. Giant Magnetocaloric Effect of Compressible Ising and Heisenberg Lattices. In Proceedings of the 7th International Conference on Magnetic Refrigeration at Room Temperature (Thermag VII), Turin, Italy, 11–14 September 2016; pp. 252–257. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Y.W.; Liu, E.K.; Ke, Y.J.; Jin, J.L.; Long, Y.; Shen, B.G. Giant rotating magnetocaloric effect induced by highly texturing in polycrystalline DyNiSi compound. Sci. Rep. 2015, 5, 11929. [Google Scholar] [CrossRef]

- Zhang, D.; Nie, Z.H.; Wang, Z.L.; Huang, L.A.; Zhang, Q.H.; Wang, Y.D. Giant magnetocaloric effect in MnCoGe with minimal Ga substitution. J. Magn. Magn. Mater. 2015, 387, 107–110. [Google Scholar] [CrossRef]

- Yin, L.H.; Yang, J.; Kan, X.C.; Song, W.H.; Dai, J.M.; Sun, Y.P. Giant magnetocaloric effect and temperature induced magnetization jump in GdCrO3 single crystal. J. Appl. Phys. 2015, 117, 133901. [Google Scholar] [CrossRef]

- Yibole, H.; Guillou, F.; Caron, L.; Jimenez, E.; de Groot, F.M.F.; Roy, P.; de Groot, R.; van Dijk, N.H.; Bruck, E. Moment evolution across the ferromagnetic phase transition of giant magnetocaloric (Mn,Fe)2(P,Si,B) compounds. Phys. Rev. B 2015, 91, 014429. [Google Scholar] [CrossRef] [Green Version]

- Wali, M.; Skini, R.; Khlifi, M.; Dhahri, E.; Hlil, E.K. A giant magnetocaloric effect with a tunable temperature transition close to room temperature in Na-deficient La0.8Na0.2−x□xMnO3 manganites. Dalton Trans. 2015, 44, 12796–12803. [Google Scholar] [CrossRef]

- Wagh, A.A.; Suresh, K.G.; Kumar, P.S.A.; Elizabeth, S. Low temperature giant magnetocaloric effect in multiferroic GdMnO3 single crystals. J. Phys. D-Appl. Phys. 2015, 48, 135001. [Google Scholar] [CrossRef]

- Toyoizumi, S.; Kitazawa, H.; Kawamura, Y.; Mamiya, H.; Terada, N.; Tamura, R.; Donni, A.; Morita, K.; Tamaki, A. Sample dependence of giant magnetocaloric effect in a cluster-glass system Ho5Pd2. J. Appl. Phys. 2015, 117, 17D101. [Google Scholar] [CrossRef]

- Tkac, V.; Orendacova, A.; Cizmar, E.; Orendac, M.; Feher, A.; Anders, A.G. Giant reversible rotating cryomagnetocaloric effect in KEr(MoO4)2 induced by a crystal-field anisotropy. Phys. Rev. B 2015, 92, 024406. [Google Scholar] [CrossRef]

- Teichert, N.; Kucza, D.; Yildirim, O.; Yuzuak, E.; Dincer, I.; Behler, A.; Weise, B.; Helmich, L.; Boehnke, A.; Klimova, S.; et al. Structure and giant inverse magnetocaloric effect of epitaxial Ni-Co-Mn-Al films. Phys. Rev. B 2015, 91, 184405. [Google Scholar] [CrossRef] [Green Version]

- Teichert, N.; Kucza, D.; Yildirim, O.; Hetaba, W.; Behler, A.; Yuzuak, E.; Dincer, I.; Helmich, L.; Boehnke, A.; Stoger-Pollach, M.; et al. Structure and Giant Inverse Magnetocaloric Effect of Epitaxial Ni-Co-Mn-Al Films. In Proceedings of the 2015 IEEE International Magnetics Conference (InterMag 2015), Beijing, China, 11–15 May 2015. [Google Scholar]

- Strecka, J.; Karlova, K.; Madaras, T. Giant magnetocaloric effect, magnetization plateaux and jumps of the regular Ising polyhedra. Phys. B-Condens. Matter 2015, 466, 76–85. [Google Scholar] [CrossRef] [Green Version]

- Rodionov, I.D.; Koshkid’ko, Y.S.; Cwik, J.; Quetz, A.; Pandey, S.; Aryala, A.; Dubenko, I.S.; Stadler, S.; Ali, N.; Titov, I.S.; et al. Peculiarities of giant magnetocaloric effect in Ni50Mn35In15 alloys in the vicinity of martensitic transition. In Proceedings of the 20th International Conference on Magnetism (ICM 2015); Barcelona, Spain, 5–10 July 2015. Phys. Procedia 2015, 75, 1353–1359. [Google Scholar] [CrossRef] [Green Version]

- Murthy, J.K.; Chandrasekhar, K.D.; Mahana, S.; Topwal, D.; Venimadhav, A. Giant magnetocaloric effect in Gd2NiMnO6 and Gd2CoMnO6 ferromagnetic insulators. J. Phys. D-Appl. Phys. 2015, 48, 355001. [Google Scholar] [CrossRef] [Green Version]

- Mo, Z.J.; Shen, J.; Yan, L.Q.; Gao, X.Q.; Tang, C.C.; Wu, J.F.; Sun, J.R.; Shen, B.G. A giant reversible magnetocaloric effect in Ho2PdSi3 compound. J. Alloys Compd. 2015, 618, 512–515. [Google Scholar] [CrossRef]

- Mo, Z.J.; Shen, J.; Li, L.; Liu, Y.; Tang, C.C.; Hu, F.X.; Sun, J.R.; Shen, B.G. Observation of giant magnetocaloric effect in EuTiO3. Mater. Lett. 2015, 158, 282–284. [Google Scholar] [CrossRef]

- Mo, Z.J.; Hao, Z.H.; Shen, J.; Li, L.; Wu, J.F.; Hu, F.X.; Sun, J.R.; Shen, B.G. Observation of giant magnetocaloric effect in EuTi1−xCrxO3. J. Alloys Compd. 2015, 649, 674–678. [Google Scholar] [CrossRef]

- Min, J.X.; Zhong, X.C.; Franco, V.; Tian, H.C.; Liu, Z.W.; Zheng, Z.G.; Zeng, D.C. Structure, magnetic properties and giant magnetocaloric effect of Tb4Gd1Si2.035Ge1.935Mn0.03 alloy. Intermetallics 2015, 57, 68–72. [Google Scholar] [CrossRef]

- Li, L.W.; Yuan, Y.; Zhang, Y.K.; Namiki, T.; Nishimura, K.; Pottgen, R.; Zhou, S.Q. Giant low field magnetocaloric effect and field-induced metamagnetic transition in TmZn. Appl. Phys. Lett. 2015, 107, 132401. [Google Scholar] [CrossRef]

- Ke, Y.J.; Zhang, X.Q.; Ge, H.; Ma, Y.; Cheng, Z.H. Low field induced giant anisotropic magnetocaloric effect in DyFeO3 single crystal. Chin. Phys. B 2015, 24, 037501. [Google Scholar] [CrossRef]

- Hou, X.L.; Lampen-Kelley, P.; Xue, Y.; Liu, C.Y.; Xu, H.; Han, N.; Ma, C.W.; Srikanth, H.; Phan, M.H. Formation mechanisms of NaZn13-type phase in giant magnetocaloric La-Fe-Si compounds during rapid solidification and annealing. J. Alloys Compd. 2015, 646, 503–511. [Google Scholar] [CrossRef] [Green Version]

- Guillou, F.; Ollefs, K.; Wilhelm, F.; Rogalev, A.; Yaresko, A.N.; Yibole, H.; van Dijk, N.H.; Bruck, E. Electronic and magnetic properties of phosphorus across the first-order ferromagnetic transition of (Mn,Fe)2(P,Si,B) giant magnetocaloric materials. Phys. Rev. B 2015, 92, 224427. [Google Scholar] [CrossRef]

- Dong, Q.Y.; Ma, Y.; Ke, Y.J.; Zhang, X.Q.; Wang, L.C.; Shen, B.G.; Sun, J.R.; Cheng, Z.H. Ericsson-like giant magnetocaloric effect in GdCrO4-ErCrO4 composite oxides near liquid hydrogen temperature. Mater. Lett. 2015, 161, 669–673. [Google Scholar] [CrossRef]

- Cervera, S.; Trassinelli, M.; Marangolo, M.; Carlsson, L.B.; Eddrief, M.; Etgens, V.H.; Gafton, V.; Hidki, S.; Lamour, E.; Levy, A.; et al. Hints on the origin of the thermal hysteresis suppression in giant magnetocaloric thin films irradiated with highly charged ions. In Proceedings of the XXIX International Conference on Photonic, Electronic, and Atomic Collisions (ICPEAC 2015), Toledo, Spain, 22–28 July 2015. J. Phys. Conf. Ser. 2015, 635, 012028. [Google Scholar] [CrossRef]

- Bruno, N.M.; Karaman, I.; Ross, J.H.; Huang, Y.J.J.; Li, J.G.G. The Tunable Microstructure and Its Influence on the Giant Magnetocaloric Effect in Magnetic Shape Memory Alloys. In Proceedings of the TMS Middle East—Mediterranean Materials Congress on Energy and Infrastructure Systems (MEMA 2015), Doha, Qatar, 11–14 January 2015; pp. 139–147. [Google Scholar] [CrossRef]

- Wada, H.; Nakamura, K.; Katagiri, K.; Ohnishi, T.; Yamashita, K.; Matsushita, A. Tuning the Curie temperature and thermal hysteresis of giant magnetocaloric (MnFe)2PX (X = Ge and Si) compounds by the Ru substitution. Jpn. J. Appl. Phys. 2014, 53, 063001. [Google Scholar] [CrossRef]

- Rubi, K.; Kumar, P.; Repaka, D.V.M.; Chen, R.F.; Wang, J.S.; Mahendiran, R. Giant magnetocaloric effect in magnetoelectric Eu1−xBaxTiO3. Appl. Phys. Lett. 2014, 104, 032407. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, Z.; Tka, E.; Dhahri, J.; Hlil, E.K. Giant magnetic entropy change in manganese perovskite La0.67Sr0.16Ca0.17MnO3 near room temperature. J. Alloys Compd. 2014, 615, 290–297. [Google Scholar]

- Midya, A.; Mandal, P. Giant magnetocaloric effect in ferromagnetic superconductor RuSr2GdCu2O8. J. Appl. Phys. 2014, 116, 032407. [Google Scholar] [CrossRef]

- Midya, A.; Khan, N.; Bhoi, D.; Mandal, P. Giant magnetocaloric effect in antiferromagnetic DyVO4 compound. Phys. B-Condens. Matter 2014, 448, 43–45. [Google Scholar] [CrossRef]

- Marangolo, M.; Karboul-Trojet, W.; Prieur, J.Y.; Etgens, V.H.; Eddrief, M.; Becerra, L.; Duquesne, J.Y. Surface acoustic wave triggering of giant magnetocaloric effect in MnAs/GaAs devices. Appl. Phys. Lett. 2014, 105, 162403. [Google Scholar] [CrossRef]

- Ma, S.C.; Hou, D.; Gong, Y.Y.; Wang, L.Y.; Huang, Y.L.; Zhong, Z.C.; Wang, D.H.; Du, Y.W. Giant magnetocaloric and magnetoresistance effects in ferrimagnetic Mn1.9Co0.1Sb alloy. Appl. Phys. Lett. 2014, 104, 022410. [Google Scholar] [CrossRef]

- Liu, X.G.; Feng, C.; Xiao, F.; Or, S.W.; Sun, Y.P.; Jin, C.G.; Xia, A.L. Giant Reversible Magnetocaloric Effect in Flower-like beta-Co(OH)2 Hierarchical Superstructures Self-assembled by Nanosheets. Mater. Res.-Ibero-Am. J. Mater. 2014, 17, 186–189. [Google Scholar]

- Li, Z.B.; Zhang, Y.D.; Sanchez-Valdes, C.F.; Llamazares, J.L.S.; Esling, C.; Zhao, X.; Zuo, L. Giant magnetocaloric effect in melt-spun Ni-Mn-Ga ribbons with magneto-multistructural transformation. Appl. Phys. Lett. 2014, 104, 044101. [Google Scholar] [CrossRef]

- Huang, L.; Cong, D.Y.; Suo, H.L.; Wang, Y.D. Giant magnetic refrigeration capacity near room temperature in Ni40Co10Mn40Sn10 multifunctional alloy. Appl. Phys. Lett. 2014, 104, 132407. [Google Scholar] [CrossRef]

- Guillou, F.; Yibole, H.; van Dijk, N.H.; Zhang, L.; Hardy, V.; Bruck, E. About the mechanical stability of MnFe(P,Si,B) giant-magnetocaloric materials. J. Alloys Compd. 2014, 617, 569–574. [Google Scholar] [CrossRef]

- Guillou, F.; Porcari, G.; Yibole, H.; van Dijk, N.; Bruck, E. Taming the First-Order Transition in Giant Magnetocaloric Materials. Adv. Mater. 2014, 26, 2671–2675. [Google Scholar] [CrossRef] [Green Version]

- Das, P.K.; Bhattacharyya, A.; Kulkarni, R.; Dhar, S.K.; Thamizhavel, A. Anisotropic magnetic properties and giant magnetocaloric effect of single-crystal PrSi. Phys. Rev. B 2014, 89, 134418. [Google Scholar] [CrossRef] [Green Version]

- Comtesse, D.; Gruner, M.E.; Ogura, M.; Sokolovskiy, V.V.; Buchelnikov, V.D.; Grunebohm, A.; Arroyave, R.; Singh, N.; Gottschall, T.; Gutfleisch, O.; et al. First-principles calculation of the instability leading to giant inverse magnetocaloric effects. Phys. Rev. B 2014, 89, 184403. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.H.; Gong, C.W.; Guo, Y.P.; Zhang, M.G.; Chai, Y.S. Martensitic transformation and giant magnetic entropy change in Ni42.8Mn40.3Co5.7Sn11.2 alloy. Chin. Phys. B 2014, 23, 067501. [Google Scholar] [CrossRef]

- Boutahar, A.; Lassri, H.; Hlil, E.K. Low Temperature Giant Magnetocaloric Effect and Critical Behavior in Amorphous Co100−xErx (x = 55, 65) Alloys. J. Supercond. Nov. Magn. 2014, 27, 2865–2869. [Google Scholar] [CrossRef]

- Balli, M.; Jandl, S.; Fournier, P.; Gospodinov, M.M. Anisotropy-enhanced giant reversible rotating magnetocaloric effect in HoMn2O5 single crystals. Appl. Phys. Lett. 2014, 104, 232402. [Google Scholar] [CrossRef]

- Zhou, T.J.; Cher, M.K.; Shen, L.; Hu, J.F.; Yuan, Z.M. On the origin of giant magnetocaloric effect and thermal hysteresis in multifunctional alpha-FeRh thin films. Phys. Lett. A 2013, 377, 3052–3059. [Google Scholar] [CrossRef]

- Zheng, X.Q.; Shao, X.P.; Chen, J.; Xu, Z.Y.; Hu, F.X.; Sun, J.R.; Shen, B.G. Giant magnetocaloric effect in Ho12Co7 compound. Appl. Phys. Lett. 2013, 102, 022421. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.C.; Dong, Q.Y.; Mo, Z.J.; Xu, Z.Y.; Hu, F.X.; Sun, J.R.; Shen, B.G. Low-temperature reversible giant magnetocaloric effect in the HoCuAl compound. J. Appl. Phys. 2013, 114, 163915. [Google Scholar] [CrossRef] [Green Version]

- Vopson, M.M. Theory of giant-caloric effects in multiferroic materials. J. Phys. D-Appl. Phys. 2013, 46, 345304. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Do, T.H.; Nguyen, H.Y.; Pham, T.T.; Nguyen, H.D.; Nguyen, T.N.N.; Tran, D.T.; Phan, T.L.; Yu, S.C. Influence of fabrication conditions on giant magnetocaloric effect of Ni-Mn-Sn ribbons. Adv. Nat. Sci.-Nanosci. Nanotechnol. 2013, 4, 025011. [Google Scholar] [CrossRef] [Green Version]

- Moya, X.; Hueso, L.E.; Maccherozzi, F.; Tovstolytkin, A.I.; Podyalovskii, D.I.; Ducati, C.; Phillips, L.C.; Ghidini, M.; Hovorka, O.; Berger, A.; et al. Giant and reversible extrinsic magnetocaloric effects in La0.7Ca0.3MnO3 films due to strain. Nat. Mater. 2013, 12, 52–58. [Google Scholar] [CrossRef]

- Mo, Z.J.; Shen, J.; Yan, L.Q.; Wu, J.F.; Wang, L.C.; Lin, J.; Tang, C.C.; Shen, B.G. Low-field induced giant magnetocaloric effect in TmCuAl compound. Appl. Phys. Lett. 2013, 102, 192407. [Google Scholar] [CrossRef]

- Mo, Z.J.; Shen, J.; Yan, L.Q.; Tang, C.C.; Lin, J.; Wu, J.F.; Sun, J.R.; Wang, L.C.; Zheng, X.Q.; Shen, B.G. Low field induced giant magnetocaloric effect in TmGa compound. Appl. Phys. Lett. 2013, 103, 052409. [Google Scholar] [CrossRef]

- Midya, A.; Khan, N.; Bhoi, D.; Mandal, P. 3d-4f spin interaction induced giant magnetocaloric effect in zircon-type DyCrO4 and HoCrO4 compounds. Appl. Phys. Lett. 2013, 103, 092402. [Google Scholar] [CrossRef] [Green Version]

- Liu, E.K.; Zhang, H.G.; Xu, G.Z.; Zhang, X.M.; Ma, R.S.; Wang, W.H.; Chen, J.L.; Zhang, H.W.; Wu, G.H.; Feng, L.; et al. Giant magnetocaloric effect in isostructural MnNiGe-CoNiGe system by establishing a Curie-temperature window. Appl. Phys. Lett. 2013, 102, 122405. [Google Scholar] [CrossRef]

- Li, D.X.; Yamamura, T.; Nimori, S.; Homma, Y.; Honda, F.; Aoki, D. Giant and isotropic low temperature magnetocaloric effect in magnetic semiconductor EuSe. Appl. Phys. Lett. 2013, 102, 152409. [Google Scholar] [CrossRef]

- Huo, J.T.; Zhao, D.Q.; Bai, H.Y.; Axinte, E.; Wang, W.H. Giant magnetocaloric effect in Tm-based bulk metallic glasses. J. Non-Cryst. Solids 2013, 359, 1–4. [Google Scholar] [CrossRef]

- Gupta, S.B.; Suresh, K.G. Giant low field magnetocaloric effect in soft ferromagnetic ErRuSi. Appl. Phys. Lett. 2013, 102, 022408. [Google Scholar] [CrossRef]

- Gupta, S.; Suresh, K.G. Observation of giant magnetocaloric effect in HoCoSi. Mater. Lett. 2013, 113, 195–197. [Google Scholar] [CrossRef] [Green Version]

- Caron, L.; Miao, X.F.; Klaasse, J.C.P.; Gama, S.; Bruck, E. Tuning the giant inverse magnetocaloric effect in Mn2−xCrxSb compounds. Appl. Phys. Lett. 2013, 103, 112404. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Xu, Z.Y.; Zheng, X.Q.; Shen, J.; Hua, F.X.; Sun, J.R.; Shen, B.G. Giant magnetic refrigerant capacity in Ho3Al2 compound. Solid State Commun. 2012, 152, 1127–1130. [Google Scholar] [CrossRef]

- Pankratov, N.Y.; Mitsiuk, V.I.; Krokhotin, A.I.; Smarzhevskaya, A.I.; Govor, G.A.; Nikitin, S.A.; Ryzhkovskii, V.M. Giant magnetocaloric effect in the region of magnetic phase transition in Mn(As,Sb) compounds. Magn. Magn. Mater. V 2012, 190, 343–346. [Google Scholar] [CrossRef]

- Ou, Z.Q.; Caron, L.; Dung, N.H.; Zhang, L.; Bruck, E. Interstitial boron in MnFe(P,As) giant-magnetocaloric alloy. Results Phys. 2012, 2, 110–113. [Google Scholar] [CrossRef] [Green Version]

- Midya, A.; Khan, N.; Bhoi, D.; Mandal, P. Giant magnetocaloric effect in magnetically frustrated EuHo2O4 and EuDy2O4 compounds. Appl. Phys. Lett. 2012, 101, 132415. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Gottschall, T.; Skokov, K.P.; Moore, J.D.; Gutfleisch, O. Giant magnetocaloric effect driven by structural transitions. Nat. Mater. 2012, 11, 620–626. [Google Scholar] [CrossRef] [PubMed]

- Li, L.W.; Nishimura, K.; Hutchison, W.D.; Qian, Z.H.; Huo, D.X.; NamiKi, T. Giant reversible magneto-caloric effect in ErMn2Si2 compound with a second order magnetic phase transition. Appl. Phys. Lett. 2012, 100, 152403. [Google Scholar] [CrossRef]

- Li, L.W.; Kadonaga, M.; Huo, D.X.; Qian, Z.H.; Namiki, T.; Nishimura, K. Low field giant magnetocaloric effect in RNiBC (R = Er and Gd) and enhanced refrigerant capacity in its composite materials. Appl. Phys. Lett. 2012, 101, 122401. [Google Scholar] [CrossRef]

- Li, L.W.; Hutchison, W.D.; Huo, D.X.; Namiki, T.; Qian, Z.H.; Nishimura, K. Low-field giant reversible magnetocaloric effect in intermetallic compound ErCr2Si2. Scr. Mater. 2012, 67, 237–240. [Google Scholar] [CrossRef]

- Duquesne, J.Y.; Prieur, J.Y.; Canalejo, J.A.; Etgens, V.H.; Eddrief, M.; Ferreira, A.L.; Marangolo, M. Ultrasonic triggering of giant magnetocaloric effect in MnAs thin films. Phys. Rev. B 2012, 86, 035207. [Google Scholar] [CrossRef] [Green Version]

- Dung, D.D.; Tuan, D.A.; Thiet, D.V.; Shin, Y.; Cho, S. Giant magnetocaloric effect of Mn0.92Ba0.08As thin film grown on Al2O3 substrate. J. Appl. Phys. 2012, 111, 07C310. [Google Scholar]

- Midya, A.; Das, S.N.; Mandal, P.; Pandya, S.; Ganesan, V. Anisotropic magnetic properties and giant magnetocaloric effect in antiferromagnetic RMnO3 crystals (R = Dy, Tb, Ho, and Yb). Phys. Rev. B 2011, 84, 235127. [Google Scholar] [CrossRef] [Green Version]

- Medeiros, F.C.; Mello, V.D.; Dantas, A.L.; Sales, F.H.S.; Carrico, A.S. Giant magnetocaloric effect of thin Ho films. J. Appl. Phys. 2011, 109, 07A914. [Google Scholar]

- Manosa, L.; Gonzalez-Alonso, D.; Planes, A.; Barrio, M.; Tamarit, J.L.; Titov, I.S.; Acet, M.; Bhattacharyya, A.; Majumdar, S. Inverse barocaloric effect in the giant magnetocaloric La-Fe-Si-Co compound. Nat. Commun. 2011, 2, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Li, L.W.; Nishimura, K.; Kadonaga, M.; Qian, Z.H.; Huo, D.X. Giant magnetocaloric effect in antiferromagnetic borocarbide superconductor RNi2B2C (R = Dy, Ho, and Er) compounds. J. Appl. Phys. 2011, 110, 043912. [Google Scholar] [CrossRef]

- Kim, M.S.; Sung, N.H.; Son, Y.; Ko, M.S.; Cho, B.K. Giant reversible anisotropic magnetocaloric effect in an antiferromagnetic EuFe2As2 single crystal. Appl. Phys. Lett. 2011, 98, 172509. [Google Scholar] [CrossRef]

- Jin, J.L.; Zhang, X.Q.; Li, G.K.; Cheng, Z.H.; Zheng, L.; Lu, Y. Giant anisotropy of magnetocaloric effect in TbMnO3 single crystals. Phys. Rev. B 2011, 83, 184431. [Google Scholar] [CrossRef]

- Fabbrici, S.; Kamarad, J.; Arnold, Z.; Casoli, F.; Paoluzi, A.; Bolzoni, F.; Cabassi, R.; Solzi, M.; Porcari, G.; Pernechele, C.; et al. From direct to inverse giant magnetocaloric effect in Co-doped NiMnGa multifunctional alloys. Acta Mater. 2011, 59, 412–419. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, P.; Kim, K.; Yu, S.C.; Dan, N.H.; Hou, X.L. Magnetic Properties and Giant Magnetocaloric Effects on the NiMn0.9Sb0.1 Compound. J. Korean Phys. Soc. 2010, 57, 1983–1986. [Google Scholar]

- Yuzuak, E.; Emre, B.; Elerman, Y.; Yucel, A. Giant magnetocaloric effect in Tb5Ge2−xSi2−xMn2x compounds. Chin. Phys. B 2010, 19, 057501. [Google Scholar]

- Xu, P.F.; Nie, S.H.; Meng, K.K.; Wang, S.L.; Chen, L.; Zhao, J.H. Co doping enhanced giant magnetocaloric effect in Mn1−xCoxAs films epitaxied on GaAs (001). Appl. Phys. Lett. 2010, 97, 042502. [Google Scholar] [CrossRef]

- Trung, N.T.; Zhang, L.; Caron, L.; Buschow, K.H.J.; Bruck, E. Giant magnetocaloric effects by tailoring the phase transitions. Appl. Phys. Lett. 2010, 96, 172504. [Google Scholar] [CrossRef]

- Szymczak, R.; Kolano, R.; Kolano-Burian, A.; Dyakonov, V.P.; Szymczak, H. Giant Magnetocaloric Effect in Manganites. Acta Phys. Pol. A 2010, 117, 203–206. [Google Scholar] [CrossRef]

- Shamba, P.; Zeng, R.; Wang, J.Q.; Dou, S.X. A sign of field-induced first order magnetic state transition and giant reversible magnetocaloric effect in cobalt hydroxide nanosheets. J. Appl. Phys. 2010, 107, 09A919. [Google Scholar] [CrossRef] [Green Version]

- Nikitin, S.A.; Skokov, K.P.; Koshkid’ko, Y.S.; Pastushenkov, Y.G.; Ivanova, T.I. Giant Rotating Magneto-caloric Effect in the Region of Spin-Reorientation Transition in the NdCo5 Single Crystal. Phys. Rev. Lett. 2010, 105, 137205. [Google Scholar] [CrossRef] [PubMed]

- Manosa, L.; Gonzalez-Alonso, D.; Planes, A.; Bonnot, E.; Barrio, M.; Tamarit, J.L.; Aksoy, S.; Acet, M. Giant solid-state barocaloric effect in the Ni-Mn-In magnetic shape-memory alloy. Nat. Mater. 2010, 9, 478–481. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mahato, R.N.; Sethupathi, K.; Sankaranarayanan, V.; Nirmala, R. Co-existence of giant magnetoresistance and large magnetocaloric effect near room temperature in nanocrystalline La0.7Te0.3MnO3. J. Magn. Magn. Mater. 2010, 322, 2537–2540. [Google Scholar] [CrossRef]

- Li, D.X.; Nimori, S.; Shikama, T. Giant and anisotropic magnetocaloric effect in antiferromagnetic single crystalline DySb. Solid State Commun. 2010, 150, 1865–1868. [Google Scholar] [CrossRef]

- Debnath, J.C.; Zeng, R.; Kim, J.H.; Dou, S.X. Giant magnetic entropy change in colossal magnetoresistance in La0.7 Ca0.3MnO3 material in low field. J. Appl. Phys. 2010, 107, 09A916. [Google Scholar] [CrossRef]

- de Medeiros, L.G.; de Oliveira, N.A.; Troper, A. Giant magnetocaloric and barocaloric effects in Mn(As1−xSbx). J. Alloys Compd. 2010, 501, 177–182. [Google Scholar] [CrossRef]

- Chen, J.; Shen, B.G.; Dong, Q.Y.; Sun, J.R. Giant magnetic entropy change in antiferromagnetic DyCuSi compound. Solid State Commun. 2010, 150, 1429–1431. [Google Scholar] [CrossRef]

- Chen, J.; Shen, B.G.; Dong, Q.Y.; Sun, J.R. Giant magnetocaloric effect in HoGa compound over a large temperature span. Solid State Commun. 2010, 150, 157–159. [Google Scholar] [CrossRef]

- Chen, J.; Shen, B.G.; Dong, Q.Y.; Hu, F.X.; Sun, J.R. Giant reversible magnetocaloric effect in metamagnetic HoCuSi compound. Appl. Phys. Lett. 2010, 96, 152501. [Google Scholar] [CrossRef] [Green Version]

- Belozorov, D.P.; Lubyaniy, L.Z.; Ravlik, A.G.; Rusakova, A.V.; Samofalov, V.N. Prospects of Development of Magnetizing Systems with Strong Stray Field for Refrigerators Based on Giant Magnetocaloric Effect. Metallofiz. I Noveishie Tekhnol. 2010, 32, 1591–1599. [Google Scholar]

- Talik, E.; Klimczak, M. Giant magnetocaloric effect in Tb3Rh. J. Alloys Compd. 2009, 486, L30–L33. [Google Scholar] [CrossRef]

- Li, L.W.; Nishimura, K.; Yamane, H. Giant reversible magnetocaloric effect in antiferromagnetic GdCo2B2 compound. Appl. Phys. Lett. 2009, 94, 102509. [Google Scholar] [CrossRef]

- Li, L.W.; Nishimura, K. Giant reversible magnetocaloric effect in antiferromagnetic superconductor Dy0.9Tm0.1Ni2B2C compound. Appl. Phys. Lett. 2009, 95, 132505. [Google Scholar] [CrossRef]

- Zou, J.D.; Wada, H.; Shen, B.G.; Sun, J.R.; Li, W. Giant magnetocaloric effect and soft-mode magneto-structural phase transition in MnAs. EPL 2008, 81, 47002. [Google Scholar] [CrossRef]

- Wang, Y.T.; Bai, H.Y.; Pan, M.X.; Zhao, D.Q.; Wang, W.H. Giant enhancement of magnetocaloric effect in metallic glass matrix composite. Sci. China Ser. G-Phys. Mech. Astron. 2008, 51, 337–348. [Google Scholar] [CrossRef]

- von Ranke, P.J.; de Oliveira, N.A.; Plaza, E.J.R.; de Sousa, V.S.R.; Alho, B.P.; Carvalho, A.M.G.; Gama, S.; Reis, M.S. The giant anisotropic magnetocaloric effect in DyAl2. J. Appl. Phys. 2008, 104, 093906. [Google Scholar] [CrossRef] [Green Version]

- Sun, N.K.; Cui, W.B.; Li, D.; Geng, D.Y.; Yang, F.; Zhang, Z.D. Giant room-temperature magnetocaloric effect in Mn1−xCrxAs. Appl. Phys. Lett. 2008, 92, 072504. [Google Scholar] [CrossRef]

- Phan, M.H.; Woods, G.T.; Chaturvedi, A.; Stefanoski, S.; Nolas, G.S.; Srikanth, H. Long-range ferro-magnetism and giant magnetocaloric effect in type VIII Eu8Ga16Ge30 clathrates. Appl. Phys. Lett. 2008, 93, 252505. [Google Scholar] [CrossRef] [Green Version]

- Manekar, M.; Roy, S.B. Reproducible room temperature giant magnetocaloric effect in Fe-Rh. J. Phys. D-Appl. Phys. 2008, 41, 192004. [Google Scholar] [CrossRef]

- Manekar, M.; Roy, S.B. Thermomagnetic history effects across the first order magneto-structural transition in the giant magnetocaloric Fe-Rh alloy. Eur. Phys. J. B 2008, 64, 19–25. [Google Scholar] [CrossRef]

- Liu, X.H.; Liu, W.; Hu, W.J.; Guo, S.; Lv, X.K.; Cui, W.B.; Zhao, X.G.; Zhang, Z.D. Giant reversible magnetocaloric effect in cobalt hydroxide nanoparticles. Appl. Phys. Lett. 2008, 93, 202502. [Google Scholar] [CrossRef]

- Huu, C.X.; Chau, N.; The, N.D.; Hoa, N.Q. Giant magnetocaloric effect at room temperature and low-field change in Fe78−xCrxSi4Nb5B12Cu1 amorphous alloys. J. Korean Phys. Soc. 2008, 53, 763–765. [Google Scholar] [CrossRef]

- Balli, M.; Fruchart, D.; Gignoux, D.; Dupuis, C.; Kedous-Lebouc, A.; Zach, R. Giant magnetocaloric effect in Mn1−x(Ti0.5V0.5)xAs: Experiments and calculations. J. Appl. Phys. 2008, 103, 103908. [Google Scholar] [CrossRef]

- Zhang, X.X.; Zhang, B.; Yu, S.; Liu, Z.; Xu, W.; Liu, G.; Chen, J.; Cao, Z.; Wu, G. Combined giant inverse and normal magnetocaloric effect for room-temperature magnetic cooling. Phys. Rev. B 2007, 76, 132403. [Google Scholar] [CrossRef] [Green Version]

- Xie, S.H.; Li, J.Q.; Zhuang, Y.H. Influence of boron on the giant magnetocaloric effect of La(Fe0.9Si0.1)13. J. Magn. Magn. Mater. 2007, 311, 589–593. [Google Scholar] [CrossRef]

- Ulyanov, A.N.; Kim, J.S.; Shin, G.M.; Kang, Y.M.; Yoo, S.I. Giant magnetic entropy change in La0.7Ca0.3MnO3 in low magnetic field. J. Phys. D-Appl. Phys. 2007, 40, 123–126. [Google Scholar] [CrossRef]

- Samanta, T.; Das, I.; Banerjee, S. Giant magnetocaloric effect in antiferromagnetic ErRu2Si2 compound. Appl. Phys. Lett. 2007, 91, 152506. [Google Scholar] [CrossRef]

- Du, J.; Cui, W.B.; Zhang, Q.; Ma, S.; Xiong, D.K.; Zhang, Z.D. Giant magnetocaloric effect in epsilon-(Mn0.83Fe0.17)3.25Ge antiferromagnet. Appl. Phys. Lett. 2007, 90, 042510. [Google Scholar] [CrossRef]

- Xu, C.; Li, G.D.; Wang, L.G. Itinerant-electron metamagnetic transition and giant magnetocaloric effect in La0.8Ce0.2Fe11.4 Si1.6 compound. J. Appl. Phys. 2006, 99, 123913. [Google Scholar] [CrossRef]

- Tocado, L.; Palacios, E.; Burriel, R. Adiabatic measurement of the giant magnetocaloric effect in MnAs. J. Therm. Anal. Calorim. 2006, 84, 213–217. [Google Scholar] [CrossRef]

- Sun, Y.; Arnold, Z.; Kamarad, J.; Wang, G.J.; Shen, B.G.; Cheng, Z.H. Pressure enhancement of the giant magnetocaloric effect in LaFe11.6Si1.4. Appl. Phys. Lett. 2006, 89, 172513. [Google Scholar] [CrossRef]

- Srinath, S.; Gass, J.; Rebar, D.J.; Woods, G.T.; Srikanth, H.; Nolas, G.S. Giant magnetocaloric effect in clathrates. J. Appl. Phys. 2006, 99, 08K902. [Google Scholar] [CrossRef]

- Li, J.Q.; Liu, F.S.; Ao, W.Q.; Zhuang, Y.H.; Zhou, K.W. Influence of carbon on the giant magnetocaloric effect of LaFe11.7Si1.3. Rare Met. 2006, 25, 556–561. [Google Scholar] [CrossRef]

- Chau, N.; Thanh, P.Q.; Hoa, N.Q.; The, N.D. The existence of giant magnetocaloric effect and laminar structure in Fe73.5−xCrxSi13.5B9Nb3Cu1. J. Magn. Magn. Mater. 2006, 304, 36–40. [Google Scholar] [CrossRef]

- Chau, N.; Hanh, D.T.; Tho, N.D.; Luong, N.H. Spin glass-like behavior, giant magnetocaloric and giant magnetoresistance effect in PrPb manganites. J. Magn. Magn. Mater. 2006, 303, E335–E338. [Google Scholar] [CrossRef]

- Sun, L.; Yibole, H.; Tegus, O.; Guillou, F. Magnetocaloric Effect, Magnetoresistance of Sc0.28Ti0.72Fe2, and Phase Diagrams of Sc0.28Ti0.72Fe2−xTx Alloys with T = Mn or Co. Crystals 2020, 10, 410. [Google Scholar] [CrossRef]

- Biswas, A.; Zarkevich, N.A.; Mudryk, Y.; Pathak, A.K.; Balema, V.; Johnson, D.D.; Pecharsky, V.K. Controlling magnetostructural transition and magnetocaloric effect in multi-component transition-metal-based materials. In preparation 2020. [Google Scholar]

- Razaq, D.S.; Kurniawan, B.; Munazat, D.R.; Watanabe, K.; Tanaka, H. Role of Potassium Substitution in the Magnetic Properties and Magnetocaloric Effect in La0.8−xKxBa0.05 Sr0.15MnO3 (0≤x≤0.20). Crystals 2020, 10, 407. [Google Scholar] [CrossRef]

- Tegus, O.; Brück, E.; Buschow, K.H.J.; de Boer, F.R. Transition-metal-based magnetic refrigerants for room-temperature applications. Nature 2002, 415, 150–152. [Google Scholar] [CrossRef] [PubMed]

- Gimaev, R.; Spichkin, Y.; Kovalev, B.; Kamilov, K.; Zverev, V.; Tishin, A. Review on magnetic refrigeration devices based on HTSC materials. Int. J. Refrig.-Rev. Int. Du Froid 2019, 100, 1–12. [Google Scholar] [CrossRef]

- Tishin, A.M.; Spichkin, Y.I.; Zverev, V.I.; Egolf, P.W. A review and new perspectives for the magnetocaloric effect: New materials and local heating and cooling inside the human body. Int. J. Refrig.-Rev. Int. Du Froid 2016, 68, 177–186. [Google Scholar] [CrossRef]

- Tishin, A.M.; Spichkin, Y.I. Recent progress in magnetocaloric effect: Mechanisms and potential applications. Int. J. Refrig.-Rev. Int. Du Froid 2014, 37, 223–229. [Google Scholar] [CrossRef]

- Zarkevich, N.A. Structural database for reducing cost in materials design and complexity of multiscale computations. Complexity 2006, 11, 36–42. [Google Scholar] [CrossRef]

- Wei, Z.-Y.; Liu, E.-K.; Li, Y.; Xu, G.-Z.; Zhang, X.-M.; Liu, G.-D.; Xi, X.-K.; Zhang, H.-W.; Wang, W.-H.; Wu, G.-H.; et al. Unprecedentedly Wide Curie-Temperature Windows as Phase-Transition Design Platform for Tunable Magneto-Multifunctional Materials. Adv. Electron. Mater. 2015, 1, 1500076. [Google Scholar] [CrossRef] [Green Version]

- Maxwell, J.C.T. Theory of Heat; Longmans, Green, and Company: London, UK, 1872. [Google Scholar]

- Kuz’min, M.D.; Tishin, A.M. Magnetocaloric effect. Part 1: An introduction to various aspects of theory and practice. Cryogenics 1992, 32, 545–558. [Google Scholar] [CrossRef]

- Rosensweig, R.E. Heating magnetic fluid with alternating magnetic field. J. Magn. Magn. Mater. 2002, 252, 370–374. [Google Scholar] [CrossRef]

- Kallumadil, M.; Tada, M.; Nakagawa, T.; Abe, M.; Southern, P.; Pankhurst, Q.A. Suitability of commercial colloids for magnetic hyperthermia. J. Magn. Magn. Mater. 2009, 321, 1509–1513. [Google Scholar] [CrossRef]

- Landau, L.D.; Lifshitz, E.M. Statistical Physics, Part 1. In Course of Theoretical Physics; Butterworth-Heinemann: Oxford, UK, 1980; Volume 5. [Google Scholar]

- Zverev, V.I.; Tishin, A.M.; Kuz’min, M.D. The maximum possible magnetocaloric ΔT effect. J. Appl. Phys. 2010, 107, 043907. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Gschneidner, K.A.; Pecharsky, A.O.; Tishin, A.M. Thermodynamics of the magnetocaloric effect. Phys. Rev. B 2001, 64, 144406. [Google Scholar] [CrossRef]

- Tishin, A.M. Magnetocaloric effect in the vicinity of magnetic phase transition. J. Magn. Magn. Mater. 1998, 184, 62–66. [Google Scholar] [CrossRef]

- Kuz’min, M.D. Landau-type parametrization of the equation of state of a ferromagnet. Phys. Rev. B 2008, 77, 184431. [Google Scholar] [CrossRef]

- Zverev, V.I.; Tishin, A.M.; Chernyshov, A.S.; Mudryk, Y.; Gschneidner, K.A., Jr.; Pecharsky, V.K. Magnetic and magnetothermal properties and the magnetic phase diagram of high purity single crystalline terbium along the easy magnetization direction. J. Phys. Condens. Matter 2014, 26, 066001. [Google Scholar] [CrossRef] [PubMed]

- Zverev, V.I.; Tishin, A.M.; Min, Z.; Mudryk, Y.; Gschneidner, K.A., Jr.; Pecharsky, V.K. Magnetic and magnetothermal properties, and the magnetic phase diagram of single-crystal holmium along the easy magnetization direction. J. Phys. Condens. Matter 2015, 27, 146002. [Google Scholar] [CrossRef] [Green Version]

- Zarkevich, N.A.; Johnson, D.D. Shape-memory transformations of NiTi: Minimum-energy pathways between austenite, martensites, and kinetically limited intermediate states. Phys. Rev. Lett. 2014, 113, 265701. [Google Scholar] [CrossRef]

- Zarkevich, N.A.; Johnson, D.D. Stable atomic structure of {NiTi} austenite. Phys. Rev. B 2014, 90, 060102. [Google Scholar] [CrossRef] [Green Version]

- Ibarra, M.R.; Algarabel, P.A. Giant volume magnetostriction in the FeRh alloy. Phys. Rev. B 1994, 50, 4196–4199. [Google Scholar] [CrossRef]

- Algarabel, P.A.; Ibarra, M.R.; Marquina, C.; del Moral, A.; Galibert, J.; Iqbal, M.; Askenazy, S. Giant room-temperature magnetoresistance in the FeRh alloy. Appl. Phys. Lett. 1995, 66, 3061–3063. [Google Scholar] [CrossRef]

- Kouvel, J.S.; Hartelius, C.C. Anomalous Magnetic Moments and Transformations in the Ordered Alloy FeRh. J. Appl. Phys. 1962, 33, 1343–1344. [Google Scholar] [CrossRef]

- Morellon, L.; Blasco, J.; Algarabel, P.A.; Ibarra, M.R. Nature of the first-order antiferromagnetic-ferromagnetic transition in the Ge-rich magnetocaloric compounds Gd5(SixGe1−x)4. Phys. Rev. B 2000, 62, 1022–1026. [Google Scholar] [CrossRef]

- du Tremolet de Lacheisserie, E. Magnetic properties and critical behaviour of GdAl2: Thermal expansion, magnetization, magnetostriction and magnetocaloric effect. J. Magn. Magn. Mater. 1988, 73, 289–298. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, Z.; Shan, G.; Bobev, S.; Shek, C.H. Abnormal thermal expansion, multiple transitions, magnetocaloric effect, and electronic structure of Gd6Co4.85. J. Appl. Phys. 2015, 118, 133903. [Google Scholar] [CrossRef]

- Owens-Baird, B.; Sousa, J.P.S.; Ziouani, Y.; Petrovykh, D.Y.; Zarkevich, N.A.; Johnson, D.D.; Kolen’ko, Y.V.; Kovnir, K. Crystallographic facet selective HER catalysis: Exemplified in FeP and NiP2 single crystals. Chem. Sci. 2020, 11, 5007–5016. [Google Scholar] [CrossRef] [Green Version]

- Qian, S.; Geng, Y.; Wang, Y.; Ling, J.; Hwang, Y.; Radermacher, R.; Takeuchi, I.; Cui, J. A review of elastocaloric cooling: Materials, cycles and system integrations. Int. J. Refrig. 2016, 64, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Tušek, J.; Engelbrecht, K.; Eriksen, D.; Dall’Olio, S.; Tušek, J.; Pryds, N. A regenerative elastocaloric heat pump. Nat. Energy 2016, 1, 16134. [Google Scholar] [CrossRef]

- Mañosa, L.; Planes, A. Materials with Giant Mechanocaloric Effects: Cooling by Strength. Adv. Mater. 2017, 29, 1603607. [Google Scholar] [CrossRef] [PubMed]

- Flerov, I.N.; Mikhaleva, E.A.; Gorev, M.V.; Kartashev, A.V. Caloric and multicaloric effects in oxygen ferroics and multiferroics. Phys. Solid State 2015, 57, 429–441. [Google Scholar] [CrossRef]

- Binek, C.; Burobina, V. Near-room-temperature refrigeration through voltage-controlled entropy change in multiferroics. Appl. Phys. Lett. 2013, 102, 031915. [Google Scholar] [CrossRef] [Green Version]

- Zarkevich, N.A.; Johnson, D.D. Magneto-structural transformations via a solid-state nudged elastic band method: Application to iron under pressure. J. Chem. Phys. 2015, 143, 064707. [Google Scholar] [CrossRef] [PubMed]