First Two-Way Electrochemical Sensor for the Detection of the Pollutant 2,4-Dinitrophenylhydrazine and Its Metabolite Based on Cu-Containing Tungstophosphate and Graphene Oxide

Abstract

:1. Introduction

2. Results and Discussion

2.1. Spectroscopic Characterization of Cu4P4W30

2.2. Electrochemical Characterization of Cu4P4W30 in Solution and on the Composite Film

2.3. Film Characterization Containing Cu4P4W30

2.3.1. UV-Vis Spectra Characterization

2.3.2. Electrochemical Characterization

2.3.3. Effective Surface Area Evaluation of the Film-Modified Electrode

2.4. Electrocatalytic Activity of the ITO/(Cu4P4W30/PDDA-GO)6 Electrode for the Reduction of 2,4-DNPH

2.4.1. Electrocatalytic Activity of Bare ITO Electrode for the Reduction of 2,4-DNPH

2.4.2. Electrocatalytic Activity of the ITO/(Cu4P4W30/PDDA-GO)6 Electrode for the Reduction of 2,4-DNPH

2.4.3. Effect of the Layer Number of the Film (Cu4P4W30/PDDA-GO)n on the Electrocatalytic Activity for the Reduction of 2,4-DNPH

2.5. Effect of pH Value on the Reduction Peak Potential of 2,4-DNPH

2.6. Sensing Performance of the ITO/(Cu4P4W30/PDDA-GO)7 Electrode

2.7. Stability, Reproducibility, and Repeatability Evaluation of the Film-Modified Electrodes

3. Materials and Method

3.1. Materials

3.2. Preparation of the Film-Modified Electrode

3.2.1. The Pretreatment of the Substrates

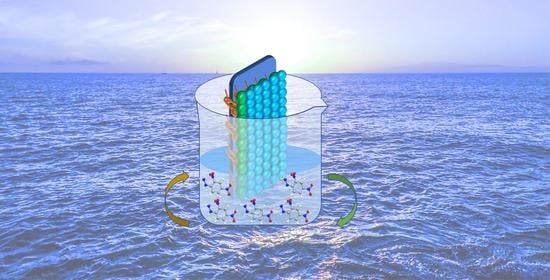

3.2.2. Fabrication of the Film on the Substrates

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adeosun, W.; Asiri, A.; Marwani, H. Real Time Detection and Monitoring of 2, 4-Dinitrophenylhydrazine in Industrial Effluents and Water Bodies by Electrochemical Approach Based on Novel Conductive Polymeric Composite. Ecotoxicol. Environ. Saf. 2020, 206, 111171. [Google Scholar] [CrossRef]

- Li, J.; Joelle, E.; Yang, Q.; Zheng, F.; Liu, J. Determination of Residual Phenylhydrazines in Drug Substances by High-Performance Liquid Chromatography with Pre-column Derivatization. Anal. Methods 2019, 11, 6146–6152. [Google Scholar] [CrossRef]

- Meng, Z.; Yin, J.; Zhao, F.; Li, M.; Zhang, Y.; Liang, Y.; Wang, Z.; Yang, Y. An Efficient Chitosan-Based Naphthalimide-Modified Fluorescent Sensor for Rapid Detection of 2,4-Dinitrophenylhydrazine and Its Applications in Environmental Analysis. Eur. Polym. J. 2021, 158, 110705. [Google Scholar] [CrossRef]

- Malaei, R.; Ramezani, A.; Absalan, G. Analysis of Malondialdehyde in Human Plasma Samples Through Derivatization with 2,4-Dinitrophenylhydrazine by Ultrasound-Assisted Dispersive Liquid–Liquid Microextraction-GC-FID Approach. J. Chromatogr. B 2018, 1089, 60–69. [Google Scholar] [CrossRef] [PubMed]

- Panchompoo, J.; Aldous, L.; Downing, C.; Crossley, A.; Compton, R. Facile Synthesis of Pd Nanoparticle Modified Carbon Black for Electroanalysis: Application to the Detection of Hydrazine. Electroanalysis 2011, 23, 1568–1578. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, X.; Wu, Y. Highly Sensitive and Selective Fluorescence Probe for 2,4-Dinitrophenylhydrazine Detection in Wastewater Using Water-Soluble CdTe QDs. Photochem. Photobiol. 2019, 95, 895–900. [Google Scholar] [CrossRef]

- Chiş, V.; Filip, S.; Miclǎuş, V.; Pîrnǎu, A.; Tǎnǎselia, C.; Almǎşan, V.; Vasilescu, M. Vibrational Spectroscopy and Theoretical Studies on 2,4-Dinitrophenylhydrazine. J. Mol. Struc. 2005, 744–747, 363–368. [Google Scholar] [CrossRef]

- Yilmaz, B.; Asci, A.; Kucukoglu, K.; Albayrak, M. Simple High-Performance Liquid Chromatography Method for Formaldehyde Determination in Human Tissue through Derivatization with 2,4-Dinitrophenylhydrazine. J. Sep. Sci. 2016, 39, 2963–2969. [Google Scholar] [CrossRef]

- Boumya, W.; Hammani, H.; Laghrib, F.; Lahrich, S.; Farahi, A.; Achak, M.; Bakasse, M.; Mhammedi, M.A.E. Electrochemical Study of 2,4-Dinitrophenylhydrazine as Derivatization Reagent and Aldehydes at Carbon Glassy Electrode. Electroanalysis 2017, 29, 1700–1711. [Google Scholar] [CrossRef]

- Boumya, W.; Achak, M.; Bakasse, M.; el Mhammedi, M. Indirect Determination of Dopamine and Paracetamol by Electrochemical Impedance Spectroscopy Using Azo Coupling Reaction with Oxidized 2,4-Dinitrophenylhydrazine (DNPH): Application in Commercial Tablets. J. Sci. Adv. Mater. Dev. 2020, 5, 218–223. [Google Scholar] [CrossRef]

- Zhang, E.; Ju, P.; Zhang, Z.; Yang, H.; Tang, L.; Hou, X.; You, J.; Wang, J. jiang A Novel Multi-Purpose Zn-MOF Fluorescent Sensor for 2,4-Dinitrophenylhydrazine, Picric Acid, La3+ and Ca2+: Synthesis, Structure, Selectivity, Sensitivity and Recyclability. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2019, 222, 117207. [Google Scholar] [CrossRef] [PubMed]

- Singha, J.; Samanta, T.; Shunmugam, R. Unusual Redshift Due to Selective Hydrogen Bonding between F-Ion and Sensor Motif: A Naked Eye Colorimetric Sensor for F-Ions in an Aqueous Environment. Mater. Adv. 2020, 1, 2346–2356. [Google Scholar] [CrossRef]

- Hassoni, F.; Mashkour, M. Spectrophotometric Determination of Anti-Ulcer Drug (Cimetidine) By 2.4-Dinitrophenylhydrazine Reagent. J. Pharm. Negat. Results 2022, 13, 192–199. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, X.; Bai, J.; Jiang, X.; Fan, G. High Sensitivity Hydrogen Peroxide and Hydrazine Sensor Based on Silver Nanocubes with Rich {100} Facets as an Enhanced Electrochemical Sensing Platform. Biosens. Bioelectron. 2013, 43, 180–185. [Google Scholar] [CrossRef]

- Boumya, W.; Hammani, H.; Loudiki, A.; Achak, M.; Aboulkas, A.; Bakasse, M.; el Mhammedi, M. Use of the Oxidizing Effect of Copper (II) to Determine 2,4-Dinitrophenylhydrazine at Glassy Electrode by Chronoamperometry. J. Electroanal. Chem. 2015, 759, 77–81. [Google Scholar] [CrossRef]

- Yu, X.; Pei, J.; Bi, L. Electrochemical Sensor Based on Polyoxometalate immobilized Using Layer-by-Layer Assembly Process to Detect 2,4-Dinitrophenylhydrazine. New. J. Chem. 2022, 46, 10777–10786. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, J.; Streb, C.; Song, Y. Recent advances on high-nuclear polyoxometalate clusters. Coord. Chem. Rev. 2022, 471, 214734. [Google Scholar] [CrossRef]

- Ke, D.; Huang, S.; Yang, G. Lanthanide-Anderson Polyoxometalates Frameworks: Efficient Sulfide Photooxidation. Inorg. Chem. 2022, 61, 20080–20086. [Google Scholar] [CrossRef]

- Li, B.; Xuan, L.; Wu, L. Polyoxometalate-Containing Supramolecular Gels. Macromol. Rapid Commun. 2022, 43, 2200019. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, X.; Fu, Z.; Pei, J.; Bi, L. Fabrication of Six Manganese Containing Polyoxometalate Modified Graphite C3N4 Nanosheets Catalysts Used to Catalyze Water Decomposition. Catalysts 2021, 11, 856. [Google Scholar] [CrossRef]

- Pei, J.; Bi, L. Application of Composite Film Containing Polyoxometalate Ni25 and Reduced Graphene Oxide for Photoelectrocatalytic Water Oxidation. Catalysts 2022, 12, 696. [Google Scholar] [CrossRef]

- Keita, B.; Mbomekalle, I.; Nadjo, L. Redox Behaviours and Electrocatalytic Properties of Copper within Dawson Structure-Derived Sandwich Heteropolyanions [Cu4(H2O)2(X2W15O56)2]16− (X = P or As). Electrochem. Commun. 2003, 5, 830–837. [Google Scholar] [CrossRef]

- Kinke, R.; Droege, M.; Domaille, P. Trivacant Heteropolytungstate Derivatives. Rational Syntheses, Characterization, Two-Dimensional Tungsten-183 NMR, and Properties of Tungstometallophosphates P2W18M4(H2O)2O6810− and P4W30M4(H2O)2O11216− (M = cobalt, copper, zinc). Inorg. Chem. 1987, 26, 3886–3896. [Google Scholar] [CrossRef]

- Inagaki, M.; Kang, F. Graphene Derivatives: Graphane, Fluorographene, Graphene Oxide, Graphyne and Graphdiyne. J. Mater. Chem. A Mater. 2014, 2, 13193–13206. [Google Scholar] [CrossRef]

- Sattar, T. Current Review on Synthesis, Composites and Multifunctional Properties of Graphene. Top. Curr. Chem. 2019, 377, 10. [Google Scholar] [CrossRef]

- Monajjemi, M. Metal-Doped Graphene Layers Composed with Boron Nitride–Graphene as an Insulator: A Nano-Capacitor. J. Mol. Model. 2014, 20, 1–8. [Google Scholar] [CrossRef]

- Deka, M.; Baruah, U.; Chowdhury, D. Insight into Electrical Conductivity of Graphene and Functionalized Graphene: Role of Lateral Dimension of Graphene Sheet. Mater. Chem. Phys. 2015, 163, 236–244. [Google Scholar] [CrossRef]

- Hong, X.; Wang, X.; Li, Y.; Fu, J.; Liang, B. Progress in Graphene/Metal Oxide Composite Photocatalysts for Degradation of Organic Pollutants. Ctalysts 2020, 10, 921. [Google Scholar] [CrossRef]

- Baig, N.; Ihsanullah; Sajid, M.; Saleh, T. Graphene-Based Adsorbents for the Removal of Toxic Organic Pollutants: A Review. J. Environ. Manag. 2019, 244, 370–382. [Google Scholar] [CrossRef]

- Gao, W.; Zheng, D.; Dong, Z.; Wu, L.; Bi, L. Preparation of Green Luminescence Composite Film and Study of Electrofluorochromic Performance. J. Electroanal. Chem. 2015, 756, 30–35. [Google Scholar] [CrossRef]

- Ensafi, A.; Heydari-Soureshjani, E.; Jafari-Asl, M.; Rezaei, B. Polyoxometalate-Decorated Graphene Nanosheets and Carbon Nanotubes, Powerful Electrocatalysts for Hydrogen Evolution Reaction. Carbon 2016, 99, 398–406. [Google Scholar] [CrossRef]

- Zhang, L.; Li, S.; Zhang, Z.; Tan, L.; Pang, H.; Ma, H. Facile Fabrication of Reduced Graphene Oxide and Keggin-Type Polyoxometalates Nanocomposite Film for High Performance Electrocatalytic Oxidation of Nitrite. J. Electroanal. Chem. 2017, 807, 97–103. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, H.; Feng, L.; Li, X.; An, Q. A Scalable Interfacial Engineering Strategy for a Finely Tunable, Homogeneous MoS2/rGO-Based HER Catalytic Structure. Adv. Mater. Interfaces 2020, 7, 1902022. [Google Scholar] [CrossRef]

- Ribicki, A.; Chemin, B.; van Haandel, V.; Winiarski, J.; de Castro Rozada, T.; Pessoa, C.; Estrada, R.; Fiorin, B.; Fujiwara, S. Sol Gel Synthesis of 3-n-Propyl(4-Aminomethyl)Pyridinium Silsesquioxane Chloride and the Enhanced Electrocatalytic Activity of LbL Films. J. Solgel Sci. Technol. 2018, 87, 216–229. [Google Scholar] [CrossRef]

- de Lima, L.; Daikuzono, C.; Miyazaki, C.; Pereira, E.; Ferreira, M. Layer-by-Layer Nanostructured Films of Magnetite Nanoparticles and Polypyrrole towards Synergistic Effect on Methylparaben Electrochemical Detection. Appl. Surf. Sci. 2020, 505, 144278. [Google Scholar] [CrossRef]

- Almeida, L.; Rodrigues, B.; Balogh, D.; Sanfelice, R.; Mercante, L.; Frade-Barros, A.; Pavinatto, A. Chitosan/Gold Nanoparticles Nanocomposite Film for Bisphenol A Electrochemical Sensing. Electrochem 2022, 3, 239–247. [Google Scholar] [CrossRef]

- Guzmán, E.; Ortega, F.; Rubio, R. Layer-by-Layer Materials for the Fabrication of Devices with Electrochemical Applications. Energies 2022, 15, 3399. [Google Scholar] [CrossRef]

- Yokus, O.; Kardas, F.; Akyildirim, O.; Eren, T.; Atar, N.; Yola, M. Sensitive Voltammetric Sensor Based on Polyoxometalate/reduced Graphene Oxide Nanomaterial: Application to the Simultaneous Determination of L-Tyrosine and L-Tryptophan. Sensor. Actuat. B-Chem. 2016, 233, 47–54. [Google Scholar] [CrossRef]

- Jiao, J.; Zuo, J.W.; Pang, H.J.; Tan, L.C.; Chen, T.; Ma, H.Y. A dopamine electrochemical sensor based on Pd-Pt alloy nanoparticles decorated polyoxometalate and multiwalled carbon nanotubes. J. Electroanal. Chem. 2018, 827, 103–111. [Google Scholar] [CrossRef]

- Boumya, W.; Hammani, H.; Loudiki, A.; Achak, M.; Bakasse, M.; el Mhammedi, M.A. Electrochemical Impedance Spectroscopic Investigation in Detecting 2,4-Dinitrophenylhydrazine Using Catalytic Effect of Copper at Glassy Electrode. Electroanalysis 2016, 28, 2965–2971. [Google Scholar] [CrossRef]

- Peng, X.; Wang, Y.; Luo, Z.; Zhang, B.; Mei, X.; Yang, X. Facile Synthesis of Fluorescent Sulfur Quantum Dots for Selective Detection of p-Nitrophenol in Water Samples. Microchem. J. 2021, 170, 106735. [Google Scholar] [CrossRef]

- Kovtyukhova, N.; Perea-López, N.; Terrones, M.; Mallouk, T. Atomically Thin Layers of Graphene and Hexagonal Boron Nitride Made by Solvent Exfoliation of Their Phosphoric Acid Intercalation Compounds. ACS Nano 2017, 11, 6746–6754. [Google Scholar] [CrossRef] [PubMed]

- Ji, J.; Jia, Y.; Wu, W.; Bai, L.; Ge, L.; Gu, Z. A Layer-by-Layer Self-Assembled Fe2O3 Nanorod-Based Composite Multilayer Film on ITO Anode in Microbial Fuel Cell. Colloids Surf. A Physicochem. Eng. Asp. 2011, 390, 56–61. [Google Scholar] [CrossRef]

- Elzbieciak, M.; Kolasińska, M.; Zapotoczny, S.; Krastev, R.; Nowakowska, M.; Warszyński, P. Nonlinear Growth of Multilayer Films Formed from Weak Polyelectrolytes. Colloids Surf. A Physicochem. Eng. Asp. 2009, 343, 89–95. [Google Scholar] [CrossRef]

| Material | Electrode | Technique | LOD (nM) | Linear Range (μM) | Reference |

|---|---|---|---|---|---|

| P-pABA-MnO2 | GCE | LSV | 80 | 0.5–90 | [1] |

| Zn-MOF | - | Fluorescence | 100 | 0.1–500 | [11] |

| CuII ions | GCE | CA | 5.5 | 0.01–10 | [15] |

| (P8W48/PDDA)7 | ITO | CV | 12 | 1.0–700 | [16] |

| CuII ions | GCE | EIS | 40 | 0.01–100 | [40] |

| (Cu4P4W30/PDDA-GO)7 | ITO | CV | 35.6 | 1.0–40 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Yu, X.; Pei, J.; Bi, L. First Two-Way Electrochemical Sensor for the Detection of the Pollutant 2,4-Dinitrophenylhydrazine and Its Metabolite Based on Cu-Containing Tungstophosphate and Graphene Oxide. Catalysts 2023, 13, 769. https://doi.org/10.3390/catal13040769

Yan X, Yu X, Pei J, Bi L. First Two-Way Electrochemical Sensor for the Detection of the Pollutant 2,4-Dinitrophenylhydrazine and Its Metabolite Based on Cu-Containing Tungstophosphate and Graphene Oxide. Catalysts. 2023; 13(4):769. https://doi.org/10.3390/catal13040769

Chicago/Turabian StyleYan, Xiaolei, Xiaoxia Yu, Jianye Pei, and Lihua Bi. 2023. "First Two-Way Electrochemical Sensor for the Detection of the Pollutant 2,4-Dinitrophenylhydrazine and Its Metabolite Based on Cu-Containing Tungstophosphate and Graphene Oxide" Catalysts 13, no. 4: 769. https://doi.org/10.3390/catal13040769