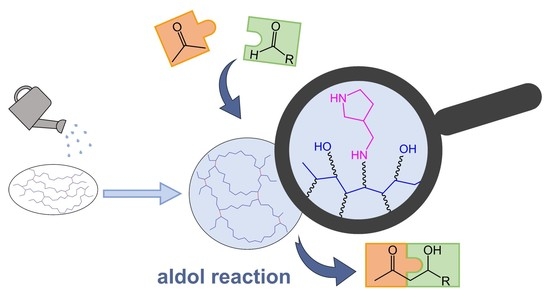

A Pyrrolidine Functionalized Poly[(ethylene glycol) Methacrylate] Resin as a Heterogeneous Catalyst for Aqueous Aldol Reactions

Abstract

:1. Introduction

- -

- -

- -

2. Results and Discussion

2.1. Catalyst Characterization

2.2. Catalyst Performance Assessment

3. Materials and Methods

3.1. Catalyst Synthesis

3.2. Catalyst Characterization

3.3. Catalyst Performance Assessment

4. Conclusions & Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. SEM Images

Appendix B. Particle Size Distribution

Appendix C. Additional 13C NMR Spectra

Appendix D. Selectivity Profiles

References

- Biesemans, B.; De Clercq, J.; Stevens, C.V.; Thybaut, J.W.; Lauwaert, J. Recent advances in amine catalyzed aldol condensations. Catal. Rev. 2022, 1–83. [Google Scholar] [CrossRef]

- List, B.; Lerner, R.A.; Barbas, C.F. Proline-Catalyzed Direct Asymmetric Aldol Reactions. J. Am. Chem. Soc. 2000, 122, 2395–2396. [Google Scholar] [CrossRef]

- Machajewski, T.D.; Wong, C.-H. The Catalytic Asymmetric Aldol Reaction. Angew. Chem. Int. Ed. 2000, 39, 1352–1375. [Google Scholar] [CrossRef]

- Hajos, Z.G.; Parrish, D.R. Asymmetric Synthesis of Organic Compounds. U.S. Patent and Trademark Office US3975440A, 8 August 1971. [Google Scholar]

- Eder, U.; Sauer, G.; Wiechert, R. New Type of Asymmetric Cyclization to Optically Active Steroid CD Partial Structures. Angew. Chem. Int. Ed. 1971, 10, 496–497. [Google Scholar] [CrossRef]

- Hajos, Z.G.; Parrish, D.R. Asymmetric synthesis of bicyclic intermediates of natural product chemistry. J. Org. Chem. 1974, 39, 1615–1621. [Google Scholar] [CrossRef]

- List, B. Proline-catalyzed asymmetric reactions. Tetrahedron 2002, 58, 5573–5590. [Google Scholar] [CrossRef]

- Emma, M.G.; Tamburrini, A.; Martinelli, A.; Lombardo, M.; Quintavalla, A.; Trombini, C. A Simple and Efficient Protocol for Proline-Catalysed Asymmetric Aldol Reaction. Catalysts 2020, 10, 649. [Google Scholar] [CrossRef]

- Melchiorre, P.; Marigo, M.; Carlone, A.; Bartoli, G. Asymmetric Aminocatalysis—Gold Rush in Organic Chemistry. Angew. Chem. Int. Ed. 2008, 47, 6138–6171. [Google Scholar] [CrossRef]

- The Nobel Prize in Chemistry. 2021. Available online: https://www.nobelprize.org/prizes/chemistry/2021/summary/ (accessed on 21 October 2021).

- Sakthivel, K.; Notz, W.; Bui, T.; Barbas, C.F. Amino Acid Catalyzed Direct Asymmetric Aldol Reactions: A Bioorganic Approach to Catalytic Asymmetric Carbon−Carbon Bond-Forming Reactions. J. Am. Chem. Soc. 2001, 123, 5260–5267. [Google Scholar] [CrossRef]

- Brunelli, N.A.; Venkatasubbaiah, K.; Jones, C.W. Cooperative Catalysis with Acid–Base Bifunctional Mesoporous Silica: Impact of Grafting and Co-condensation Synthesis Methods on Material Structure and Catalytic Properties. Chem. Mater. 2012, 24, 2433–2442. [Google Scholar] [CrossRef]

- Lauwaert, J.; De Canck, E.; Esquivel, D.; Thybaut, J.W.; Van Der Voort, P.; Marin, G.B. Silanol-Assisted Aldol Condensation on Aminated Silica: Understanding the Arrangement of Functional Groups. ChemCatChem 2014, 6, 255–264. [Google Scholar] [CrossRef]

- Lauwaert, J.; Moschetta, E.G.; Van Der Voort, P.; Thybaut, J.W.; Jones, C.W.; Marin, G.B. Spatial arrangement and acid strength effects on acid–base cooperatively catalyzed aldol condensation on aminosilica materials. J. Catal. 2015, 325, 19–25. [Google Scholar] [CrossRef] [Green Version]

- Lauwaert, J.; De Canck, E.; Esquivel, D.; Van Der Voort, P.; Thybaut, J.W.; Marin, G.B. Effects of amine structure and base strength on acid–base cooperative aldol condensation. Catal. Today 2015, 246, 35–45. [Google Scholar] [CrossRef]

- Collier, V.E.; Ellebracht, N.C.; Lindy, G.I.; Moschetta, E.G.; Jones, C.W. Kinetic and Mechanistic Examination of Acid–Base Bifunctional Aminosilica Catalysts in Aldol and Nitroaldol Condensations. ACS Catal. 2016, 6, 460–468. [Google Scholar] [CrossRef]

- Hoyt, C.B.; Lee, L.-C.; Cohen, A.E.; Weck, M.; Jones, C.W. Bifunctional Polymer Architectures for Cooperative Catalysis: Tunable Acid–Base Polymers for Aldol Condensation. ChemCatChem 2017, 9, 137–143. [Google Scholar] [CrossRef]

- Kandel, K.; Althaus, S.M.; Peeraphatdit, C.; Kobayashi, T.; Trewyn, B.G.; Pruski, M.; Slowing, I.I. Solvent-Induced Reversal of Activities between Two Closely Related Heterogeneous Catalysts in the Aldol Reaction. ACS Catal. 2013, 3, 265–271. [Google Scholar] [CrossRef] [Green Version]

- De Vylder, A.; Lauwaert, J.; Esquivel, D.; Poelman, D.; De Clercq, J.; Van Der Voort, P.; Thybaut, J.W. The role of water in the reusability of aminated silica catalysts for aldol reactions. J. Catal. 2018, 361, 51–61. [Google Scholar] [CrossRef]

- Z Andrade, K.C.; Alves, M.L. Environmentally Benign Solvents in Organic Synthesis: Current Topics. Curr. Org. Chem. 2005, 9, 195–218. [Google Scholar] [CrossRef]

- Ranu, B.C.; Saha, A.; Dey, R. Using more environmentally friendly solvents and benign catalysts in performing conventional organic reactions. Curr. Opin. Drug Discov. Dev. 2010, 13, 658–668. [Google Scholar]

- Jing, Y.; Guo, Y.; Xia, Q.; Liu, X.; Wang, Y. Catalytic Production of Value-Added Chemicals and Liquid Fuels from Lignocellulosic Biomass. Chem 2019, 5, 2520–2546. [Google Scholar] [CrossRef]

- De Vylder, A.; Lauwaert, J.; Van Auwenis, S.; De Clercq, J.; Thybaut, J.W. Catalyst Stability Assessment in a Lab-Scale Liquid-Solid (LS)² Plug-Flow Reactor. Catalysts 2019, 9, 755. [Google Scholar] [CrossRef]

- Font, D.; Jimeno, C.; Pericàs, M.A. Polystyrene-Supported Hydroxyproline: An Insoluble, Recyclable Organocatalyst for the Asymmetric Aldol Reaction in Water. Org. Lett. 2006, 8, 4653–4655. [Google Scholar] [CrossRef] [PubMed]

- Salam, N.; Mondal, P.; Mondal, J.; Roy, A.S.; Bhaumik, A.; Islam, S.M. Highly efficient base catalysis and sulfide oxidation reactions over new functionalized mesoporous polymers. RSC Adv. 2012, 2, 6464–6477. [Google Scholar] [CrossRef]

- Xiao, J.; Li, G.-w.; Zhang, W.-q. Aldol reactions catalyzed by proline functionalized polyacrylonitrile fiber. Chem. Res. Chin. Univ. 2013, 29, 256–262. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, C.; Ma, N.; Tao, M.; Zhang, W. Surface wettability modification of amine-functionalized polyacrylonitrile fiber to enhance heterogeneous catalytic performance for aldol reaction in water. Appl. Catal. A Gen. 2020, 608, 117842. [Google Scholar] [CrossRef]

- De Vylder, A.; Lauwaert, J.; De Clercq, J.; Van Der Voort, P.; Jones, C.W.; Thybaut, J.W. Aminated poly(ethylene glycol) methacrylate resins as stable heterogeneous catalysts for the aldol reaction in water. J. Catal. 2020, 381, 540–546. [Google Scholar] [CrossRef]

- Schmiegel, C.J.; Baier, R.; Kuckling, D. Direct Asymmetric Aldol Reaction in Continuous Flow Using Gel-Bound Organocatalysts. Eur. J. Org. Chem. 2021, 2021, 2578–2586. [Google Scholar] [CrossRef]

- Xiao, W.; Wang, Z.; Yang, J.; Chen, T.; Yi, C.; Xu, Z. Engineering of polystyrene-supported acid–base catalysts for aldol condensation in water. New J. Chem. 2022, 46, 12318–12323. [Google Scholar] [CrossRef]

- Shajahan, R.; Sarang, R.; Saithalavi, A. Polymer Supported Proline-Based Organocatalysts in Asymmetric Aldol Reactions: A Review. Curr. Organocatal. 2022, 9, 124–146. [Google Scholar] [CrossRef]

- Tuncel, A. Suspension polymerization of poly(ethylene glycol) methacrylate: A route for swellable spherical gel beads with controlled hydrophilicity and functionality. Colloid Polym. Sci. 2000, 278, 1126–1138. [Google Scholar] [CrossRef]

- De Vylder, A.; Lauwaert, J.; Sabbe, M.K.; Reyniers, M.-F.; De Clercq, J.; Van Der Voort, P.; Thybaut, J.W. Rational design of nucleophilic amine sites via computational probing of steric and electronic effects. Catal. Today 2019, 334, 96–103. [Google Scholar] [CrossRef]

- Singh, S.; Chimni, S.S. Pyrrolidine catalyzed diastereoselective direct aldol reaction in water: A green approach. Indian J. Chem. 2013, 52B, 1202–1209. [Google Scholar]

- Harris, J.M.; Hundley, N.H.; Shannon, T.G.; Struck, E.C. Polyethylene glycols as soluble, recoverable, phase-transfer catalysts. J. Org. Chem. 1982, 47, 4789–4791. [Google Scholar] [CrossRef]

- Gravert, D.J.; Janda, K.D. Organic Synthesis on Soluble Polymer Supports: Liquid-Phase Methodologies. Chem. Rev. 1997, 97, 489–510. [Google Scholar] [CrossRef]

- Kandel, K.; Althaus, S.M.; Peeraphatdit, C.; Kobayashi, T.; Trewyn, B.G.; Pruski, M.; Slowing, I.I. Substrate inhibition in the heterogeneous catalyzed aldol condensation: A mechanistic study of supported organocatalysts. J. Catal. 2012, 291, 63–68. [Google Scholar] [CrossRef]

- Lauwaert, J.; Ouwehand, J.; De Clercq, J.; Cool, P.; Van Der Voort, P.; Thybaut, J.W. Tuning component enrichment in amino acid functionalized (organo)silicas. Catal. Commun. 2017, 88, 85–89. [Google Scholar] [CrossRef] [Green Version]

- De Vylder, A.; Lauwaert, J.; Sabbe, M.K.; Reyniers, M.-F.; De Clercq, J.; Van Der Voort, P.; Thybaut, J.W. A comprehensive model for the role of water and silanols in the amine catalyzed aldol reaction. Chem. Eng. J. 2021, 404, 127070. [Google Scholar] [CrossRef]

- Bartók, M. Advances in Immobilized Organocatalysts for the Heterogeneous Asymmetric Direct Aldol Reactions. Catal. Rev. 2015, 57, 192–255. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Pineault, H.; Brunelli, N.A. Quantifying the fraction and activity of catalytic sites at different surface densities of aminosilanes in SBA-15 for the aldol reaction and condensation. J. Catal. 2022, 413, 1048–1055. [Google Scholar] [CrossRef]

- Córdova, A.; Notz, W.; Barbas Iii, C.F. Direct organocatalytic aldol reactions in buffered aqueous media. Chem. Commun. 2002, 3024–3025. [Google Scholar] [CrossRef]

- Nyberg, A.I.; Usano, A.; Pihko, P.M. Proline-Catalyzed Ketone-Aldehyde Aldol Reactions are Accelerated by Water. Synlett 2004, 2004, 1891–1896. [Google Scholar] [CrossRef]

- Córdova, A.; Zou, W.; Ibrahem, I.; Reyes, E.; Engqvist, M.; Liao, W.-W. Acyclic amino acid-catalyzed direct asymmetric aldol reactions: Alanine, the simplest stereoselective organocatalyst. Chem. Commun. 2005, 3586–3588. [Google Scholar] [CrossRef] [PubMed]

- Doyagüez, E.G.; Calderón, F.; Sánchez, F.; Fernández-Mayoralas, A. Asymmetric Aldol Reaction Catalyzed by a Heterogenized Proline on a Mesoporous Support. The Role of the Nature of Solvents. J. Org. Chem. 2007, 72, 9353–9356. [Google Scholar] [CrossRef] [PubMed]

- Vachan, B.S.; Karuppasamy, M.; Vinoth, P.; Sridharan, V.; Menéndez, J.C. Chapter 6—Stereoselective organic synthesis in water: Organocatalysis by proline and its derivatives. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Inamuddin, Boddula, R., Asiri, A.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 191–229. [Google Scholar] [CrossRef]

- Christensen, J.J.; Izatt, R.M.; Wrathall, D.P.; Hansen, L.D. Thermodynamics of proton ionization in dilute aqueous solution. Part XI. pK, ΔH°, and ΔS° values for proton ionization from protonated amines at 25°. J. Chem. Soc. A Inorg. Phys. Theor. 1969, 1212–1223. [Google Scholar] [CrossRef]

- Singappuli-Arachchige, D.; Kobayashi, T.; Wang, Z.; Burkhow, S.J.; Smith, E.A.; Pruski, M.; Slowing, I.I. Interfacial Control of Catalytic Activity in the Aldol Condensation: Combining the Effects of Hydrophobic Environments and Water. ACS Catal. 2019, 9, 5574–5582. [Google Scholar] [CrossRef]

- Lauwaert, J.; Van de Steene, E.; Vermeir, P.; De Clercq, J.; Thybaut, J.W. Critical Assessment of the Thermodynamics in Acidic Resin-Catalyzed Esterifications. Ind. Eng. Chem. Res. 2020, 59, 22079–22091. [Google Scholar] [CrossRef]

- Di Carmine, G.; Forster, L.; Wang, S.; Parlett, C.; Carlone, A.; D’Agostino, C. NMR relaxation time measurements of solvent effects in an organocatalysed asymmetric aldol reaction over silica SBA-15 supported proline. React. Chem. Eng. 2022, 7, 269–274. [Google Scholar] [CrossRef]

- Brunelli, N.A.; Didas, S.A.; Venkatasubbaiah, K.; Jones, C.W. Tuning Cooperativity by Controlling the Linker Length of Silica-Supported Amines in Catalysis and CO2 Capture. J. Am. Chem. Soc. 2012, 134, 13950–13953. [Google Scholar] [CrossRef]

- Brunelli, N.A.; Jones, C.W. Tuning acid–base cooperativity to create next generation silica-supported organocatalysts. J. Catal. 2013, 308, 60–72. [Google Scholar] [CrossRef]

- Han, G.; Tamaki, M.; Hruby, V.J. Fast, efficient and selective deprotection of the tert-butoxycarbonyl (Boc) group using HCl/dioxane (4 m). J. Pept. Res. 2001, 58, 338–341. [Google Scholar] [CrossRef]

- Huybrechts, W.; Lauwaert, J.; De Vylder, A.; Mertens, M.; Mali, G.; Thybaut, J.W.; Van Der Voort, P.; Cool, P. Synthesis of L-serine modified benzene bridged periodic mesoporous organosilica and its catalytic performance towards aldol condensations. Microporous Mesoporous Mater. 2017, 251, 1–8. [Google Scholar] [CrossRef]

- Houlleberghs, M.; Hoffmann, A.; Dom, D.; Kirschhock, C.E.A.; Taulelle, F.; Martens, J.A.; Breynaert, E. Absolute Quantification of Water in Microporous Solids with 1H Magic Angle Spinning NMR and Standard Addition. Anal. Chem. 2017, 89, 6940–6943. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Radhakrishnan, S.; Colaux, H.; Chandran, C.V.; Dom, D.; Verheyden, L.; Taulelle, F.; Martens, J.; Breynaert, E. Trace Level Detection and Quantification of Crystalline Silica in an Amorphous Silica Matrix with Natural Abundance 29Si NMR. Anal. Chem. 2020, 92, 13004–13009. [Google Scholar] [CrossRef] [PubMed]

- Massiot, D.; Fayon, F.; Capron, M.; King, I.; Le Calvé, S.; Alonso, B.; Durand, J.-O.; Bujoli, B.; Gan, Z.; Hoatson, G. Modelling one- and two-dimensional solid-state NMR spectra. Magn. Reson. Chem. 2002, 40, 70–76. [Google Scholar] [CrossRef]

| PEGMA | PEGMA-Cl | PEGMA-AMP | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| wt% of C | 53 ± 3% | 53 ± 3% | 56 ± 4% | 57 ± 4% | 57 ± 4% |

| wt% of H | 8.6 ± 0.5% | 8.4 ± 0.1% | 10 ± 0.05% | 9.7 ± 0.05% | 9.3 ± 0.05% |

| wt% of O | 36 ± 3% | 29 ± 3% | 26 ± 4% | 25 ± 4% | 25 ± 4% |

| wt% of Cl | - | 7.4 ± 3% | 7.1 ± 4% | 6.2 ± 3% | 5.7 ± 4% |

| wt% of N | - | - | 0.2 ± 0.04% | 0.54 ± 0.04% | 0.8 ± 0.07% |

| nAMP [mmol g−1] | - | - | 0.054 ± 0.008 | 0.190 ± 0.019 | 0.270 ± 0.014 |

| Water | Acetone/Water (50/50 vol%) | Acetone | Acetone/N-Hexane (50/50 vol%) | n-Hexane | |

|---|---|---|---|---|---|

| S | 3.0 ± 0.3 | 2.9 ± 0.3 | 1.8 ± 0.3 | 1.4 ± 0.3 | 1.1 ± 0.2 |

| Entry | Catalyst | T [°C] | Solvent | TOF [s−1] |

|---|---|---|---|---|

| 1 | PEGMA-supported pyrrolidine (PEGMA-AMP) | 55 | water | 3.0 ± 1.5 × 10−3 |

| 2 | PEGMA-supported Me-substituted secondary amine [28] | 55 | water | 0.31 ± 0.02 × 10−3 |

| 3 | PEGMA-supported primary amine [28] | 55 | water | 0.63 ± 0.04 × 10−3 |

| 4 | PEGMA-supported pyrrolidine (PEGMA-AMP) | 55 | n-hexane | 0.006 ± 0.0001 × 10−3 |

| 5 | Silica-supported Me-substituted secondary amine [15] | 45 | n-hexane | 3.30 ± 0.15 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biesemans, B.; Aljammal, N.; Radhakrishnan, S.; Breynaert, E.; Stevens, C.V.; Lauwaert, J.; Thybaut, J.W. A Pyrrolidine Functionalized Poly[(ethylene glycol) Methacrylate] Resin as a Heterogeneous Catalyst for Aqueous Aldol Reactions. Catalysts 2022, 12, 1389. https://doi.org/10.3390/catal12111389

Biesemans B, Aljammal N, Radhakrishnan S, Breynaert E, Stevens CV, Lauwaert J, Thybaut JW. A Pyrrolidine Functionalized Poly[(ethylene glycol) Methacrylate] Resin as a Heterogeneous Catalyst for Aqueous Aldol Reactions. Catalysts. 2022; 12(11):1389. https://doi.org/10.3390/catal12111389

Chicago/Turabian StyleBiesemans, Bert, Noor Aljammal, Sambhu Radhakrishnan, Eric Breynaert, Christian V. Stevens, Jeroen Lauwaert, and Joris W. Thybaut. 2022. "A Pyrrolidine Functionalized Poly[(ethylene glycol) Methacrylate] Resin as a Heterogeneous Catalyst for Aqueous Aldol Reactions" Catalysts 12, no. 11: 1389. https://doi.org/10.3390/catal12111389