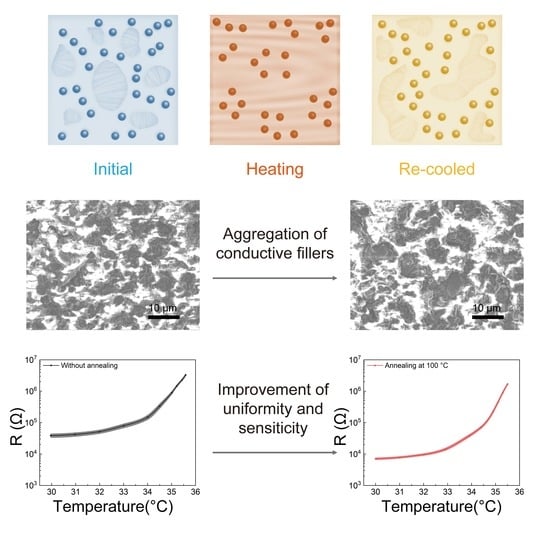

Fabrication of Temperature Sensors with High-Performance Uniformity through Thermal Annealing

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bagavathiappan, S.; Philip, J.; Jayakumar, T.; Raj, B.; Rao, P.N.S.; Varalakshmi, M.; Mohan, V. Correlation between plantar foot temperature and diabetic neuropathy: A case study by using an infrared thermal imaging technique. J. Diabetes Sci. Technol. 2010, 4, 1386–1392. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.; Ma, C.; Chen, J.; Wu, H.; Luo, W.; Peng, Y.; Luo, Z.; Li, L.; Tan, Y.; Omisore, O.M.; et al. Printable, Highly Sensitive Flexible Temperature Sensors for Human Body Temperature Monitoring: A Review. Nanoscale Res. Lett. 2020, 15, 200. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Du, M.; Li, Z. Flexible Temperature Sensors Constructed with Fiber Materials. Adv. Mater. Technol. 2022, 7, 2101182. [Google Scholar] [CrossRef]

- Charkoudian, N. Mechanisms and modifiers of reflex induced cutaneous vasodilation and vasoconstriction in humans. J. Appl. Physiol. 2010, 109, 1221–1228. [Google Scholar] [CrossRef]

- Hermanns, H.; Werdehausen, R.; Hollmann, M.W.; Stevens, M.F. Assessment of skin temperature during regional anaesthesia—What the anaesthesiologist should know. Acta Anaesthesiol. Scand. 2018, 62, 1280–1289. [Google Scholar] [CrossRef]

- Bouzida, N.; Bendada, A.; Maldague, X.P. Visualization of body thermoregulation by infrared imaging. J. Therm. Biol. 2009, 34, 120–126. [Google Scholar] [CrossRef]

- Hattori, Y.; Falgout, L.; Lee, W.; Jung, S.-Y.; Poon, E.; Lee, J.W.; Na, I.; Geisler, A.; Sadhwani, D.; Zhang, Y.; et al. Multifunctional Skin-Like Electronics for Quantitative, Clinical Monitoring of Cutaneous Wound Healing. Adv. Healthcare Mater. 2014, 3, 1597–1607. [Google Scholar] [CrossRef]

- Honda, W.; Harada, S.; Arie, T.; Akita, S.; Takei, K. Wearable, Human-Interactive, Health-Monitoring, Wireless Devices Fabricated by Macroscale Printing Techniques. Adv. Funct. Mater. 2014, 24, 3299–3304. [Google Scholar] [CrossRef]

- Chester, J.G.; Rudolph, J.L. Vital Signs in Older Patients: Age-Related Changes. J. Am. Med. Dir. Assoc. 2011, 12, 337–343. [Google Scholar] [CrossRef]

- Dąbrowska, A.; Spano, F.; Derler, S.; Adlhart, C.; Spencer, N.; Rossi, R. The relationship between skin function, barrier properties, and body-dependent factors. Skin Res. Technol. 2018, 24, 165–174. [Google Scholar] [CrossRef] [Green Version]

- Bharara, M.; Schoess, J.; Armstrong, D.G. Coming events cast their shadows before: Detecting inflammation in the acute diabetic foot and the foot in remission. Diabetes Metab. Res. Rev. 2012, 28, 15–20. [Google Scholar] [CrossRef]

- Fikackova, H.; Ekberg, E. Can infrared thermography be a diagnostic tool for arthralgia of the temporomandibular joint. Oral Surg. Oral Med. Oral Pathol. Oral. Radiol. 2004, 98, 643–650. [Google Scholar] [CrossRef]

- Ji, Y.; Duan, K.; Lu, Z.; Ren, W. Mid-infrared absorption spectroscopic sensor for simultaneous and in-situ measurements of ammonia, water and temperature. Sens. Actuators B Chem. 2022, 371, 132574. [Google Scholar] [CrossRef]

- Villa, E.; Arteaga-Marrero, N.; Ruiz-Alzola, J. Performance Assessment of Low-Cost Thermal Cameras for Medical Applications. Sensors 2020, 20, 1321. [Google Scholar] [CrossRef]

- Lahiri, B.; Bagavathiappan, S.; Jayakumar, T.; Philip, J. Medical applications of infrared thermography: A review. Infrared Phys. Technol. 2012, 55, 221–235. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Chen, A.; Chen, C. Investigation of the Impact of Infrared Sensors on Core Body Temperature Monitoring by Comparing Measurement Sites. Sensors 2020, 20, 2885. [Google Scholar] [CrossRef]

- Karino, G.; Senoo, A.; Kunikata, T.; Kamei, Y.; Yamanouchi, H.; Nakamura, S.; Shukuya, M.; Colman, R.J.; Koshiba, M. Inexpensive Home Infrared Living/Environment Sensor with Regional Thermal Information for Infant Physical and Psychological Development. Int. J. Environ. Res. Public Health 2020, 17, 6844. [Google Scholar] [CrossRef]

- Hua, Q.L.; Sun, J.L.; Liu, H.T.; Bao, R.R.; Yu, R.M.; Zhai, J.Y.; Pan, C.F.; Wang, Z.L. Skin-inspired highly stretchable and conformable matrix networks for multifunctional sensing. Nat. Commun. 2018, 9, 244. [Google Scholar] [CrossRef]

- Bang, J.; Lee, W.S.; Park, B.; Joh, H.; Woo, H.K.; Jeon, S.; Ahn, J.; Jeong, C.; Kim, T.; Oh, S.J. Highly Sensitive Temperature Sensor: Ligand-Treated Ag Nanocrystal Thin Films on PDMS with Thermal Expansion Strategy. Adv. Funct. Mater. 2019, 29, 1903047. [Google Scholar] [CrossRef]

- Han, S.; Kim, M.K.; Wang, B.; Wie, D.S.; Wang, S.; Lee, C.H. Mechanically Reinforced Skin-Electronics with Networked Nanocomposite Elastomer. Adv. Mater. 2016, 28, 10257–10265. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, B.W.; Chen, Y.H.; Feng, X. Breathable and Stretchable Temperature Sensors Inspired by Skin. Sci. Rep. 2015, 5, 11505. [Google Scholar] [CrossRef] [PubMed]

- Xiao, S.; Che, L.; Li, X.; Wang, Y. A novel fabrication process of MEMS devices on polyimide flexible substrates. Microelectron. Eng. 2008, 85, 452–457. [Google Scholar] [CrossRef]

- Webb, R.C.; Bonifas, A.P.; Behnaz, A.; Zhang, Y.; Yu, K.J.; Cheng, H.; Shi, M.; Bian, Z.; Liu, Z.; Kim, Y.-S.; et al. Ultrathin conformal devices for precise and continuous thermal characterization of human skin. Nat. Mater. 2013, 12, 938–944. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.F.; Sekine, T.; Takeda, Y.; Yokosawa, K.; Matsui, H.; Kumaki, D.; Shiba, T.; Nishikawa, T.; Tokito, S. Fully Printed PEDOT:PSS-based Temperature Sensor with High Humidity Stability for Wireless Healthcare Monitoring. Sci. Rep. 2020, 10, 2467. [Google Scholar] [CrossRef]

- Shih, W.-P.; Tsao, L.-C.; Lee, C.-W.; Cheng, M.-Y.; Chang, C.; Yang, Y.-J.; Fan, K.-C. Flexible Temperature Sensor Array Based on a Graphite-Polydimethylsiloxane Composite. Sensors 2010, 10, 3597–3610. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, H.B.R.; Bao, Z. Flexible Wireless Temperature Sensors Based on Ni Microparticle-Filled Binary Polymer Composites. Adv. Mater. 2013, 25, 850–855. [Google Scholar] [CrossRef]

- Li, G.; Hu, C.; Zhai, W.; Zhao, S.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Particle size induced tunable positive temperature coefficient characteristics in electrically conductive carbon nanotubes/polypropylene composites. Mater. Lett. 2016, 182, 314–317. [Google Scholar] [CrossRef]

- Huang, Y.; Zeng, X.; Wang, W.D.; Guo, X.H.; Hao, C.; Pan, W.D.; Liu, P.; Liu, C.X.; Ma, Y.M.; Zhang, Y.G.; et al. High-resolution flexible temperature sensor based graphite-filled polyethylene oxide and polyvinylidene fluoride composites for body temperature monitoring. Sens. Actuators A Phys. 2018, 278, 1–10. [Google Scholar] [CrossRef]

- Yokota, T.; Inoue, Y.; Terakawa, Y.; Reeder, J.; Kaltenbrunner, M.; Ware, T.; Yang, K.; Mabuchi, K.; Murakawa, T.; Sekino, M.; et al. Ultraflexible, large-area, physiological temperature sensors for multipoint measurements. Proc. Natl. Acad. Sci. USA 2015, 112, 14533–14538. [Google Scholar] [CrossRef]

- Yeh, C.-C.; Xu, M.-X.; Yang, Y.-J.J. A respiratory transducer array to exploit the ultra-sensitive temperature dependence of an acrylate-based composite for real-time respiration rate monitoring. Appl. Phys. Lett. 2019, 114, 183704. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.H.; Duan, L.L.; Zhang, W.L.; Su, M.J.; Sun, Z.G.; He, P.X. Polystyrene/graphene oxide nanocomposites synthesized via Pickering polymerization. Prog. Org. Coat. 2016, 99, 23–31. [Google Scholar] [CrossRef]

- Périard, J.D.; Eijsvogels, T.M.H.; Daanen, H.A.M. Exercise under heat stress: Thermoregulation, hydration, performance implications, and mitigation strategies. Physiol. Rev. 2021, 101, 1873–1979. [Google Scholar] [CrossRef]

- Kim, J.; Lee, D.; Park, K.; Goh, H.; Lee, Y. Silver fractal dendrites for highly sensitive and transparent polymer thermistors. Nanoscale 2019, 11, 15464–15471. [Google Scholar] [CrossRef]

- Cai, J.-H.; Li, J.; Chen, X.-D.; Wang, M. Multifunctional polydimethylsiloxane foam with multi-walled carbon nanotube and thermo-expandable microsphere for temperature sensing, microwave shielding and piezoresistive sensor. Chem. Eng. J. 2020, 393, 124805. [Google Scholar] [CrossRef]

- Trung, T.Q.; Ramasundaram, S.; Hwang, B.-U.; Lee, N.-E. An All-Elastomeric Transparent and Stretchable Temperature Sensor for Body-Attachable Wearable Electronics. Adv. Mater. 2016, 28, 502–509. [Google Scholar] [CrossRef]

- Karbovnyk, I.; Chalyy, D.; Lukashevych, D.; Klym, H. Electrical Properties at Low Temperatures of PEDOT-based Nanocomposites. In Proceedings of the 2018 International Conference on Information and Telecommunication Technologies and Radio Electronics (UkrMiCo) Proceedings, Odessa, Ukraine, 10–14 September 2018. [Google Scholar]

- Chen, Z.; Zhao, D.; Ma, R.; Zhang, X.; Rao, J.; Yin, Y.; Wang, X.; Yi, F. Flexible temperature sensors based on carbon nanomaterials. J. Mater. Chem. B 2020, 9, 1941–1964. [Google Scholar] [CrossRef]

- Bigg, D.M. Rheological behaviour of highly filled polymer melts. Polym. Eng. Sci. 1983, 23, 206–210. [Google Scholar] [CrossRef]

- Tafrishi, H.; Sadeghzadeh, S.; Ahmadi, R.; Molaei, F.; Yousefi, F.; Hassanloo, H. Investigation of tetracosane thermal transport in presence of graphene and carbon nanotube fillers––A molecular dynamics study. J. Energy Storage 2020, 29, 101321. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, G.; Zhang, B.; Zhang, Z. The influence of crystalline and aggregate structure on PTC characteristic of conductive polyethylene/carbon black composite. Eur. Polym. J. 1998, 34, 1221–1227. [Google Scholar] [CrossRef]

- Carmona, F.; Valot, E.; Servant, L.; Ricci, M. Random media with temperature controlled connectivity. J. Phys. I 1992, 2, 503–510. [Google Scholar] [CrossRef]

- Rybak, A.; Boiteux, G.; Melis, F.; Seytre, G. Conductive polymer composites based on metallic nanofiller as smart materials for current limiting devices. Compos. Sci. Technol. 2010, 70, 410–416. [Google Scholar] [CrossRef]

- Wu, L.; Qian, J.; Peng, J.; Wang, K.; Liu, Z.; Ma, T.; Zhou, Y.; Wang, G.; Ye, S. Screen-printed flexible temperature sensor based on FG/CNT/PDMS composite with constant TCR. J. Mater. Sci. Mater. Electron. 2019, 30, 9593–9601. [Google Scholar] [CrossRef]

- Yang, J.C.; Mun, J.; Kwon, S.Y.; Park, S.; Bao, Z.N.; Park, S. Electronic Skin: Recent Progress and Future Prospects for Skin-Attachable Devices for Health Monitoring, Robotics, and Prosthetics. Adv. Mater. 2019, 31, 1904765. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Li, Y.; Xie, W.; Zhou, X.; Hong, J.; Liang, J.; Liu, Y.; Li, W.; Wang, H. Fabrication of Temperature Sensors with High-Performance Uniformity through Thermal Annealing. Materials 2023, 16, 1491. https://doi.org/10.3390/ma16041491

Liu H, Li Y, Xie W, Zhou X, Hong J, Liang J, Liu Y, Li W, Wang H. Fabrication of Temperature Sensors with High-Performance Uniformity through Thermal Annealing. Materials. 2023; 16(4):1491. https://doi.org/10.3390/ma16041491

Chicago/Turabian StyleLiu, Hongrui, Yongchun Li, Weiji Xie, Xinyi Zhou, Jishuang Hong, Junfeng Liang, Yanghui Liu, Wei Li, and Hong Wang. 2023. "Fabrication of Temperature Sensors with High-Performance Uniformity through Thermal Annealing" Materials 16, no. 4: 1491. https://doi.org/10.3390/ma16041491