Effects on the Properties of Self-Compacting Cement Paste (PAA) with the Addition of Superabsorbent Polymer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Characterization

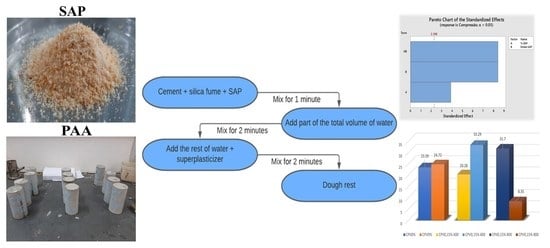

2.2. Mortar Dosing

2.3. Properties of the Pulp in the Fresh State

2.4. Properties of the Paste in the Hardened State

3. Results

3.1. Material characterization

3.2. Mortar Dosing

3.3. Mechanical Properties

4. Conclusions

- The incorporation of SAP in cement pastes influenced the self-compacting properties due to the diameter of the SAP and the type of cement, whose slump tests showed greater inconsistency for the diameter of 600 μm.

- The mechanical properties were also influenced by the incorporation of SAP in the pastes tested. The results of the compressive strength test presented very interesting values, demonstrating an increase in strength in relation to the base mixture. The best performances were observed for the mixtures that had in their composition CPII cement with in-corporation of SAP of 600 μm diameter and for the 800 μm diameter, presenting an increase of 35.2% and 34.3%, respectively, in relation to the reference mixtures.

- The results of absorption and air content corroborate the analysis of the influence of the addition of SAP on the mechanical strengths. The CPV mixture with addition of SAP with maximum diameter showed results with the highest rates of absorption and air content, with an increase of 29.2% for the absorption and 33.6% for the content, compared with the reference mixture, substantiating the reduction in compressive strength of mixture 6.

- In general, cementitious paste mixtures with the addition of SAP improve the properties analyzed. However, due to the results found for mixture 6, future works can be studied for the dry curing processes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Souza, M.H.B.; Gonçalves, P.C.; Silva, L.R.R.; Melo, M.L.N.M.; dos Santos, V.C. Use of Superabsorbent Polymers in Cement-Based Compounds: A Bibliometric Analysis. Res. Soc. Dev. 2021, 10, e171101421818. [Google Scholar] [CrossRef]

- Gomes, A.; Barros, P.C. Métodos de Dosagem de Concreto Autoadensável; Pini: São Paulo, 2009. [Google Scholar]

- Ferreira, L.; Ribeiro, F. Estudo Comparativo Do Concreto Auto Adensável Com Cinza Da Casca de Arroz Sem Controle de Queima e Sílica Ativa. Paranoá: Cad. Arquitetura Urban. 2018, 1–12. [Google Scholar] [CrossRef]

- Rosa, F.; Bordado, J.M.; Casquilho, M. Polímeros Superabsorventes Potencialidades e Aplicações. Dossier comunicações: Química. 1990, pp. 1988–1990. Available online: http://web.tecnico.ulisboa.pt/~mcasquilho/compute/_fitting/Ing98-DC_Quim8.pdf (accessed on 23 November 2022).

- Lee, H.X.D.; Wong, H.S.; Buenfeld, N.R. Self-Sealing of Cracks in Concrete Using Superabsorbent Polymers. Cem. Concr. Res. 2016, 79, 194–208. [Google Scholar] [CrossRef] [Green Version]

- Al-Hubboubi, S.; Al-Attar, T.; Al-Badry, H.; Abood, S.; Mohammed, R.; Haddhood, B. Performance of Super-Absorbent Polymer as an Internal Curing Agent for Self-Compacting Concrete. MATEC Web Conf. 2018, 162, 2023. [Google Scholar] [CrossRef] [Green Version]

- Alejandro, M.; Manzano, R.; Fonseca, E.; Neiry, A.; Lopes, D.M.; Dias, R.; Filho, T. Mecanismo de Atuação Dos Polímeros Superabsorventes Como Agentes de Cura Interna Para Mitigar a Retração Autógena Em Concretos de Alta Resistência (CAR)—Estado Da Arte Actuating Mechanism of Superabsorbent Polymers as Internal Curing Agents to Mitigat. Rev. Matéria 2021, 26, e12956. [Google Scholar] [CrossRef]

- Lura, P.; Terrasi, G. Pietro Reduction of Fire Spalling in High-Performance Concrete by Means of Superabsorbent Polymers and Polypropylene Fibers. Cem. Concr. Compos. 2014, 49, 36–42. [Google Scholar] [CrossRef] [Green Version]

- Baloch, H.; Usman, M.; Rizwan, S.A.; Hanif, A. Properties Enhancement of Super Absorbent Polymer (SAP) Incorporated Self-Compacting Cement Pastes Modified by Nano Silica (NS) Addition. Constr. Build. Mater. 2019, 203, 18–26. [Google Scholar] [CrossRef]

- Chindasiriphan, P.; Yokota, H.; Pimpakan, P. Effect of Fly Ash and Superabsorbent Polymer on Concrete Self-Healing Ability. Constr. Build. Mater. 2020, 233, 116975. [Google Scholar] [CrossRef]

- Yang, J.; Liu, L.; Liao, Q.; Wu, J.; Li, J.; Zhang, L. Effect of Superabsorbent Polymers on the Drying and Autogenous Shrinkage Properties of Self-Leveling Mortar. Constr. Build. Mater. 2019, 201, 401–407. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Tecnicas. ABNT NBR16605/2017: Cimento Portland e Outros Materiais Em Pó—Determinação Da Massa Específica; Associação Brasileira de Normas Tecnicas: Rio de Janeiro, Brazil, 2017. [Google Scholar]

- Nita, C.; John, V.M. Materiais Pozolânicos: O Metacaulim e a Sílica Ativa; Boletim Técnico da Escola Politécnica da USP: São Paulo, Brazil, 2007; p. 15. [Google Scholar]

- Rodrigues, F.; Valle, S.; Cesar, P.; Gabriela, M.; Ranieri, A. Use of Recycled Aggregates from Civil Construction in Self- Compacting Mortar. Rev. IBRACON Estrut. Mater. 2022, 15, 1–13. [Google Scholar]

- Da Silva, L.R.R. Análise de Propriedades Do Concreto Autoadensável Com Resíduo Polimérico. Master’s Thesis, Universidade Federal de Itajubá, Itajubá, Brazil, 2020. [Google Scholar]

- Fonseca Tutikian, B.; Carpena Dal Molin, D. Concreto Auto-Adensável; Pini: São Paulo, Brazil, 2008. [Google Scholar]

- Bentz, D.; Lura, P.; Roberts, J. Mixture Proportioning for Internal Curing. Concr. Int. 2005, 27, 35–40. [Google Scholar]

- Olawuyi, B.; Boshoff, W. Compressive Strength of High-Performance Concrete with Absorption Capacity of Super-Absorbent-Polymers (SAP). In Proceedings of the Research and Applications in Structural Engineering, Cape Town, South Africa, 15 August 2013; pp. 1679–1683. [Google Scholar]

- Associação Brasileira de Normas Tecnicas. ABNT NBR 5739/2018 Concreto—Ensaio de Compressão de Corpos-de-Prova Cilíndricos; Associação Brasileira de Normas Tecnicas: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- ASTM Standard C215 Standard Test Method for Fundamental Transverse, Longitudinal, and Torsional Resonant Frequencies of Concrete Specimens. 2008. Available online: http://www.astm.org/Standards/C215.htm (accessed on 22 November 2022).

- Associação Brasileira de Normas Tecnicas. ABNT NBR 9778/1987 Argamassa e Concreto Endurecidos—Determinacao Da Absorcao de Água Por Imersao—Índice de Vazios e Massa Especifica; Associação Brasileira de Normas Tecnicas: Rio de Janeiro, Brazil, 1987. [Google Scholar]

- Instituto Granado de Tecnologia da Poliacrilonitrila IGTPAN. Available online: https://www.igtpan.com/ (accessed on 1 November 2022).

- Schröfl, C.; Mechtcherine, V.; Gorges, M. Relation between the Molecular Structure and the Efficiency of Superabsorbent Polymers (SAP) as Concrete Admixture to Mitigate Autogenous Shrinkage. Cem. Concr. Res. 2012, 42, 865–873. [Google Scholar] [CrossRef]

- Agostinho, L.B.; Borges, J.G.; da Silva, E.F.; Cupertino, D.V.M.R. A Calorimetry Analysis of Portland Cement Pastes Containing Superabsorbent Polymer (Sap) and Nanosilica (Ns). Rev. Mater. 2020, 25, 1–12. [Google Scholar] [CrossRef]

| Property | Mathematical Equation |

|---|---|

| Specific mass (ρs) | ρs = ms/(msat − mi) |

| Absorption by immersion (A) | A = ((msat − ms)/ms) × 100 |

| Void index (Iv) | Iv = ((msat − ms)/(msat − mi)) × 100 |

| Composition | CPII Ref. | CPII—0.15%SAP 600 μm | CPII—0.15%SAP 800 μm | CPV Base | CPV—0.15%SAP 600 μm | CPV—0.15%SAP 800 μm |

|---|---|---|---|---|---|---|

| Number of samples | 3 | 3 | 3 | 3 | 3 | 3 |

| Cement Type | Specific Mass (g/cm3) | D50 (μm) |

|---|---|---|

| CPII-F 32 | 2.99 | 12.47 |

| CPV-ARI | 3.04 | 12.43 |

| silica fume | 2.20 | 39.78 |

| N° | Mixture | Cimente | Silica | Superplasticizer (SP) | Water a/c | SAP |

|---|---|---|---|---|---|---|

| 1 | CPII reference | 1 | 0.083 | 0.003 | 0.32 | 0.0000 |

| 2 | CPII—0.15%SAP—600 μm | 1 | 0.083 | 0.004 | 0.37 | 0.0015 |

| 3 | CPII—0.15%SAP—800 μm | 1 | 0.083 | 0.004 | 0.32 | 0.0015 |

| 4 | CPV reference | 1 | 0.083 | 0.004 | 0.34 | 0.0000 |

| 5 | CPV—0.15%SAP—600 μm | 1 | 0.083 | 0.005 | 0.36 | 0.0015 |

| 6 | CPV—0.15%SAP—800 μm | 1 | 0.083 | 0.005 | 0.39 | 0.0015 |

| N° | Mixture | T115 (s) Ref. | T115 (s) | Df (mm) Ref. | Df (mm) |

|---|---|---|---|---|---|

| 1 | CPII reference | Between 2 and 3.5 | 2.5 | Between 170 and 190 | 180 |

| 2 | CPII—0.15%SAP—600 μm | 2.0 | 177 | ||

| 3 | CPII—0.15%SAP—800 μm | 2.5 | 170 | ||

| 4 | CPV reference | 2.5 | 170 | ||

| 5 | CPV—0.15%SAP—600 μm | 2.0 | 165 | ||

| 6 | CPV—0.15%SAP—800 μm | 3.0 | 171 |

| Samples | Mixture | ME (GPA) | SM (g/cm3) | Abs (%) | AirC (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Unit. | μ | Unit. | μ | Unit. | μ | Unit. | μ | ||

| 1 | CPII base | 14.9 | 15.38 | 2.3 | 2.28 | 12.2 | 11.77 | 13.9 | 13.35 |

| 15.7 | 2.3 | 12.3 | 14.1 | ||||||

| 15.5 | 2.3 | 10.8 | 12.1 | ||||||

| 2 | CPII—0.15% SAP—600 μm | 12.6 | 12.89 | 2.3 | 2.29 | 14.3 | 13.80 | 16.7 | 15.90 |

| 13.7 | 2.3 | 13.6 | 15.7 | ||||||

| 12.4 | 2.3 | 13.5 | 15.3 | ||||||

| 3 | CPII—0.15% SAP—800 μm | 12.4 | 12.43 | 2.2 | 2.21 | 11.2 | 11.05 | 12.6 | 12.42 |

| 12.4 | 2.2 | 11.2 | 12.6 | ||||||

| 12.4 | 2.2 | 10.8 | 12.2 | ||||||

| 1 | CPV base | 13.6 | 12.88 | 2.3 | 2.31 | 12.5 | 11.75 | 13.3 | 12.99 |

| 12.5 | 2.3 | 12 | 13.6 | ||||||

| 12.6 | 2.3 | 10.8 | 12.1 | ||||||

| 2 | CPV—0.15% SAP—600 μm | 12.8 | 13.94 | 2.4 | 2.24 | 11.5 | 10.95 | 13 | 12.22 |

| 13.5 | 2.2 | 11.1 | 12.5 | ||||||

| 15.6 | 2.2 | 10.2 | 11.2 | ||||||

| 3 | CPV—0.15% SAP—800 μm | 10.8 | 10.76 | 2.2 | 2.22 | 15.9 | 15.21 | 18.9 | 17.83 |

| 10.3 | 2.2 | 14.3 | 16.3 | ||||||

| 11.1 | 2.2 | 15.5 | 18.3 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Souza, M.H.B.; Teixeira, B.A.; Gonçalves, P.C.; da Silva, L.R.R.; Melo, M.d.L.N.M.; Ribeiro, V.A.d.S.; Sachs, D.; Capellato, P.; dos Santos, V.C. Effects on the Properties of Self-Compacting Cement Paste (PAA) with the Addition of Superabsorbent Polymer. Materials 2022, 15, 8478. https://doi.org/10.3390/ma15238478

de Souza MHB, Teixeira BA, Gonçalves PC, da Silva LRR, Melo MdLNM, Ribeiro VAdS, Sachs D, Capellato P, dos Santos VC. Effects on the Properties of Self-Compacting Cement Paste (PAA) with the Addition of Superabsorbent Polymer. Materials. 2022; 15(23):8478. https://doi.org/10.3390/ma15238478

Chicago/Turabian Stylede Souza, Michel Henry Bacelar, Bárbara Almeida Teixeira, Paulo Cesar Gonçalves, Lucas Ramon Roque da Silva, Míriam de Lourdes Noronha Motta Melo, Vander Alkmin dos Santos Ribeiro, Daniela Sachs, Patrícia Capellato, and Valquíria Claret dos Santos. 2022. "Effects on the Properties of Self-Compacting Cement Paste (PAA) with the Addition of Superabsorbent Polymer" Materials 15, no. 23: 8478. https://doi.org/10.3390/ma15238478