A Platform for Outdoor Real-Time Characterization of Photovoltaic Technologies

Abstract

:1. Introduction

- (1)

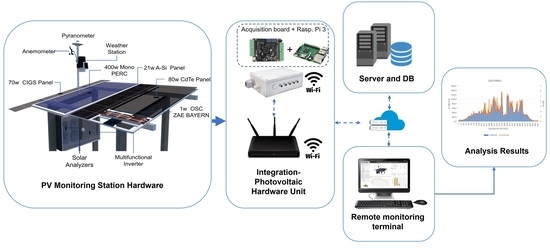

- Design of an integrated and scalable platform that accomplishes the technical requirements for performing outdoor real-time characterization of emerging PV technologies.

- (2)

- Design of a compact, modular, and portable device for acquiring, formatting, and real-time transmission of PV data. This device, here called IPHU (integration-photovoltaic hardware unit), receives and formats the data provided by the pyranometer, cell-surface temperature sensors, weather station, and PV analyzers; IPHU transmits the information to the central server via REST web service.

- (3)

- Design of a PC software application to visualize the I-V and P-V curves and meteorological and PV parameters for outdoor performance analysis during a time.

- (4)

- Development of three PV monitoring stations (PVMS) installed at 0, 1000, and 2000 m above sea level (m.a.s.l).

2. Materials and Methods

2.1. IPHU Design and Implementation

- Connecting Verification Procedure verifies the connection of IPHU with the sensors, weather station, and PV/OPV analyzers.

- Data Capture Procedure accesses and captures the data from the sensors, the weather station, and PV/OPV analyzers through the Modbus and Wi-Fi local networks. The data from the analyzers are captured using an SSH communication on a local network, and the data generated by the weather station are captured using an HTTP request to the wireless gateway.

- Data Integration Procedure performs two functions: (a) capture the temporal data and verify if these are synchronized at the date and time, and (b) integrate the synchronized data over one CSV file. In this case, the weather station, IPHU, and PV analyzers must be synchronized using the NTP server; otherwise, the data are discarded.

- Data Transmission/Storing Procedure performs two functions: (a) establish the communication between IPHU and the central server, and (b) store the data over internal memory or an external hard disk when there is no internet access for PVMS installed in remote areas.

- Diagnostic Procedure performs two functions: (a) restart IPHU when there are failures or start it in the morning, that is, reboot IPHU and the PV analyzers, and (b) register the IPHU events for diagnostic and update purposes.

2.2. Development of the Software User Interface

- Main Window displays historical and real-time data obtained from the database server, and it contains five sections, as shown in Figure 3: (1) Bar menu allows accessing the other windows and sets the user interface. (2) Dropdown menu allows selecting the PVMS and PV technology for display. (3) Control functions (start and stop) for real-time monitoring. (4) Curves display allows selecting the I-V or P-V real-time curves. (5) Meteorological parameters display shows the values of the meteorological parameters in real-time for the selected PVMS, and (6) power-generated display shows the maximum power generated by each PV technology in real-time from the selected PVMS.

- Log-in Window allows log-in to the platform as a guest or administrator. The administrator mode enables advanced functions such as power system backup configuration, monitoring errors and failures, remote restart, and software updating.

- PVMS Configuration Window allows setting the IP addresses of the measuring equipment and configuring the SSH communication between IPHU and PV/OPV analyzers.

- Data Report Window allows displaying the report on the performance of PV technologies during a specific time range (days, months, or years), using a date search function. This window presents the average values of all PV and meteorological parameters in the same time range and the average FF calculated using a pie chart, as shown in Figure 4.

2.3. Dataset Recording and Verification Tests

2.4. Outdoor Characterization Tests

- Record the PV and meteorological parameters at each PVMS for one day.

- Select PV parameters for an associate irradiance close to 1000 W/m2.

- Trace the I-V curves for the flexible CIGS and OPV modules placed in PVMS1, as is shown in Figure 5.

- Obtain the values of open-circuit voltage (Voc), short circuit current (Isc), maximum voltage (Vmpp), and maximum current (Impp) from the I-V curves.

- Graph the calculated P-V curve for the selected technologies from the I-V curves and the calculated maximum power (Pmax).

- Compare the above obtained and calculated values with the ones provided by the manufacturers.

3. Results and Discussion

3.1. Results of Maximum Power Generated

3.2. Analysis of Isc and Voc with Respect to Irr

3.3. Analysis of Voc with Respect to Tc

3.4. Outdoor Performance Results

3.4.1. Results for a Sunny Day

3.4.2. Results for Four Months

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kawagoe, K.; Hishikawa, Y.; Yamada, N. Outdoor Direct STC Performance Measurement of PV Modules Based on a Sun-Shading Technique. IEEE J. Photovolt. 2017, 7, 1725–1730. [Google Scholar] [CrossRef]

- Dolara, A.; Leva, S.; Manzolini, G. Comparison of different physical models for PV power output prediction. Sol. Energy 2015, 119, 83–99. [Google Scholar] [CrossRef] [Green Version]

- Alshayeb, M.; Chang, J.D. Photovoltaic Energy Variations Due to Roofing Choice. Procedia Eng. 2016, 145, 1104–1109. [Google Scholar] [CrossRef] [Green Version]

- Seera, M.; Tan, C.J.; Chong, K.-K.; Lim, C.P. Performance analyses of various commercial photovoltaic modules based on local spectral irradiances in Malaysia using genetic algorithm. Energy 2021, 223, 120009. [Google Scholar] [CrossRef]

- Dubey, S.; Sarvaiya, J.N.; Seshadri, B. Temperature Dependent Photovoltaic (PV) Efficiency and Its Effect on PV Production in the World—A Review. Energy Procedia 2013, 33, 311–321. [Google Scholar] [CrossRef] [Green Version]

- Zendehdel, M.; Nia, N.Y.; Yaghoubinia, M. Emerging Thin Film Solar Panels. In Reliability and Ecological Aspects of Photovoltaic Modules; IntechOpen: London, UK, 2020. [Google Scholar]

- Smets, A.H.M.; Jäger, K.; Isabella, O.; van Swaaij, R.A.; Zeman, M. Solar Cell Parameters and Equivalent Circuit. Sol. Energy Phys. Eng. Photovolt. Convers. Technol. Syst. 2016, 113–121. Available online: https://ocw.tudelft.nl/wp-content/uploads/solar_energy_section_9_1_9_3.pdf (accessed on 1 May 2022).

- Elibol, E.; Özmen, Ö.T.; Tutkun, N.; Köysal, O. Outdoor performance analysis of different PV panel types. Renew. Sustain. Energy Rev. 2017, 67, 651–661. [Google Scholar] [CrossRef]

- Freitas, A.M.; Gomes, R.A.M.; Ferreira, R.A.M.; Porto, M.P. Experimental performance of commercial OPV panels tested outdoor. Renew. Energy 2019, 135, 1004–1012. [Google Scholar] [CrossRef]

- Madeti, S.R.; Singh, S.N. Monitoring system for photovoltaic plants: A review. Renew. Sustain. Energy Rev. 2017, 67, 1180–1207. [Google Scholar] [CrossRef]

- Triki-Lahiani, A.; Bennani-Ben Abdelghani, A.; Slama-Belkhodja, I. Fault detection and monitoring systems for photovoltaic installations: A review. Renew. Sustain. Energy Rev. 2018, 82, 2680–2692. [Google Scholar] [CrossRef]

- Dolara, A.; di Fazio, G.; Leva, S.; Manzolini, G.; Simonetti, R.; Terenzi, A. Outdoor Assessment and Performance Evaluation of OPV Modules. IEEE J. Photovolt. 2021, 11, 391–399. [Google Scholar] [CrossRef]

- Choi, S.; Ishii, T.; Sato, R.; Chiba, Y.; Masuda, A. Performance degradation due to outdoor exposure and seasonal variation in amorphous silicon photovoltaic modules. Thin Solid Film. 2018, 661, 116–121. [Google Scholar] [CrossRef]

- Monteiro, L.G.; Macedo, W.N.; Cavalcante, R.L.; Junior, W.B.; Torres, P.F.; Brito, T.R.; Silva, M.M.; Lopes, B.M.; Fraga, J.M.; Alves, D.D.; et al. Field I-V Curve Measurements Methodology at String Level to Monitor Failures and the Degradation Process: A Case Study of a 1.42 MWp PV Power Plant. IEEE Access 2020, 8, 226845–226865. [Google Scholar] [CrossRef]

- Farooq, W.; Khan, A.D.; Khan, A.D.; Rauf, A.; Khan, S.D.; Ali, H.; Iqbal, J.; Khan, R.U.; Noman, M. Thin-Film Tandem Organic Solar Cells with Improved Efficiency. IEEE Access 2020, 8, 74093–74100. [Google Scholar] [CrossRef]

- Velilla, E.; Cano, J.B.; Jaramillo, F. Monitoring system to evaluate the outdoor performance of solar devices considering the power rating conditions. Sol. Energy 2019, 194, 79–85. [Google Scholar] [CrossRef]

- Tawa, H.; Ota, Y.; Inagaki, M.; Mikami, R.; Iwasaki, T.; Ueyama, M.; Nishioka, K. Comparison of CPV systems with lattice-matched and mismatched solar cells in long-term outdoor performance. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; Volume 1, pp. 961–964. [Google Scholar] [CrossRef]

- Ustun, T.S.; Nakamura, Y.; Hashimoto, J.; Otani, K. Performance analysis of PV panels based on different technologies after two years of outdoor exposure in Fukushima, Japan. Renew. Energy 2019, 136, 159–178. [Google Scholar] [CrossRef]

- Stoichkov, V.; Bristow, N.; Troughton, J.; de Rossi, F.; Watson, T.M.; Kettle, J. Outdoor performance monitoring of perovskite solar cell mini-modules: Diurnal performance, observance of reversible degradation and variation with climatic performance. Sol. Energy 2018, 170, 549–556. [Google Scholar] [CrossRef] [Green Version]

- Stoichkov, V.; Sweet, T.K.N.; Jenkins, N.; Kettle, J. Studying the outdoor performance of organic building-integrated photovoltaics laminated to the cladding of a building prototype. Sol. Energy Mater. Sol. Cells 2018, 191, 356–364. [Google Scholar] [CrossRef]

- Gao, B.; Shao, Y.; Liu, W.; Xiang, H.; Yu, Y.; Liu, Z. Outdoor reliability and degradation of HIT, CIGS, n-type multi-busbar, PERC, and CdTe modules in Shanghai, China. Sol. Energy Mater. Sol. Cells 2022, 236, 111490. [Google Scholar] [CrossRef]

- Dolara, A.; Leva, S.; Manzolini, G.; Simonetti, R.; Trattenero, I. Outdoor Performance of Organic Photovoltaics: Comparative Analysis. Energies 2022, 15, 1620. [Google Scholar] [CrossRef]

- Repins, I.; Contreras, M.A.; Egaas, B.; DeHart, C.; Scharf, J.; Perkins, C.L.; To, B.; Noufi, R. 19·9%-efficient ZnO/CdS/CuInGaSe2 solar cell with 81·2% fill factor. Prog. Photovolt. Res. Appl. 2008, 16, 235–239. [Google Scholar] [CrossRef] [Green Version]

- Garris, R.L.; Johnston, S.; Li, J.V.; Guthrey, H.L.; Ramanathan, K.; Mansfield, L.M. Electrical characterization and comparison of CIGS solar cells made with different structures and fabrication techniques. Sol. Energy Mater. Sol. Cells 2018, 174, 77–83. [Google Scholar] [CrossRef]

- Lee, T.D.; Ebong, A. Thin film solar technologies: A review. In Proceedings of the 2015 12th International Conference on High-capacity Optical Networks and Enabling/Emerging Technologies (HONET), Islamabad, Pakistan, 21–23 December 2015; pp. 33–42. [Google Scholar] [CrossRef]

- Ferekides, C.S.; Hsu, C.-A. CdTe Thin Film PV: How Has the Technology Evolved and What Challenges Lie Ahead. In Proceedings of the 2019 26th International Workshop on Active-Matrix Flatpanel Displays and Devices (AM-FPD), Kyoto, Japan, 2–5 July 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Meng, W.; Jinqing, P.; Hongxing, Y.; Yimo, L. Performance evaluation of semi-transparent CdTe thin-film PV window applying on commercial buildings in Hong Kong. Energy Procedia 2018, 152, 1091–1096. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, Y.; Wan, X.; Li, C.; Zhang, X.; Wang, Y.; Ke, X.; Xiao, Z.; Ding, L.; Xia, R.; et al. Organic and solution-processed tandem solar cells with 17.3% efficiency. Science 2018, 361, 1094–1098. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, K.; Rich, S.; Lee, S.; Fukuda, K.; Yokota, T.; Someya, T. Organic Photovoltaics: Toward Self-Powered Wearable Electronics. Proc. IEEE 2019, 107, 2137–2154. [Google Scholar] [CrossRef]

| PV Technology | CdTe | OPV | CIGS | A-Si |

|---|---|---|---|---|

| Technical reference | BIPV | ZAE BAYERN | FLEX–03 70N | Power Film 21W |

| Dimensions | 1200 × 600 mm | 9.75 cm²/cell × 20 | 1709 × 348 mm | 1544.3 × 370.8 mm |

| Weight | 11.8 kg | - | 1.56 kg | 0.7 kg |

| Maximum power (Pmax) | 77 W | - | 70 W | 21 W |

| Maximum Voltage (Vmpp) | 21 V | 9.15 V | 18.1 V | 15.4 V |

| Maximum Current (Impp) | 3.66 A | 89.22 mA | 3.88 A | 1.35 A |

| Open circuit voltage (Voc) | 28 V | 14.00 V | 23.2 V | 21.9 V |

| Short Circuit Current (Isc) | 3.91 A | 99.40 mA | 4.67 A | 1.6 A |

| Efficiency | 10.69% | 4.18% | 11.77% | 3.68% |

| Station | PV Tech. | Irr (W/m2) | Voc (v) | Isc (A) | Pmax (W) | Vmax (v) | Imax (A) | TA (°C) | Tc. (°C) | RH (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| PVMS1 0 (m.a.s.l) | OPV1 | 1033 | 12.76 | 0.10 | 0.76 | 8.69 | 0.087 | 31.83 | 58.10 | 69.30 |

| A-Si | 1033 | 19.02 | 1.79 | 15.75 | 12.55 | 1.26 | 31.83 | 54.10 | 69.30 | |

| CIGS | 1033 | 21.58 | 4.51 | 64.43 | 16.70 | 3.86 | 31.83 | 57.90 | 69.30 | |

| CdTe | 1033 | 23.42 | 4.42 | 61.32 | 16.73 | 3.67 | 31.83 | 54.00 | 69.30 | |

| PVMS2 1000 (m.a.s.l) | OPV3 | 1033 | 14.04 | 0.093 | 0.85 | 10.61 | 0.080 | 26.50 | 54.90 | 74.20 |

| A-Si | 1033 | 19.60 | 1.71 | 16.18 | 13.19 | 1.23 | 26.50 | 50.20 | 74.20 | |

| CIGS | 1033 | 20.72 | 4.38 | 59.88 | 15.98 | 3.75 | 26.50 | 51.30 | 74.20 | |

| CdTe | 1033 | 22.86 | 4.44 | 60.05 | 16.19 | 3.71 | 26.50 | 57.10 | 74.20 | |

| PVMS3 2.000 (m.a.s.l) | OPV1 | 1034 | 13.51 | 0.09 | 0.83 | 10.277 | 0.08 | 18.61 | 42.80 | 87.5 |

| A-Si | 1034 | 19.90 | 1.51 | 14.62 | 13.189 | 1.11 | 18.61 | 28.70 | 87.5 | |

| CIGS | 1034 | 21.61 | 3.80 | 51.32 | 16.740 | 3.07 | 18.61 | 41.10 | 87.5 | |

| CdTe | 1034 | 25.61 | 3.70 | 57.91 | 19.207 | 3.01 | 18.61 | 41.60 | 87.5 |

| Measurement Error (%) | |||

|---|---|---|---|

| PV Parameter | High Irr | Medium Irr | Low Irr |

| Voc (v) | 0.64% | 0.43% | 4.23% |

| Isc (A) | 0.70% | 1.64% | 2.97% |

| Pmax (W) | 0.35% | 2.24% | 0.91% |

| Vmax (v) | 0.45% | 0.01% | 4.25% |

| Imax (A) | 1.01% | 2.41% | 4.93% |

| CIGS (V/°C) | CdTe (V/°C) | A-Si (V/°C) | OPV (V/°C) | |

|---|---|---|---|---|

| PVMS1 | 0.045 | 0.084 | 0.050 | 0.023 |

| PVMS2 | 0.047 | 0.093 | 0.048 | 0.025 |

| PVMS3 | 0.043 | 0.064 | 0.051 | 0.014 |

| Average Voltage loss rate | 0.045 | 0.080 | 0,049 | 0.021 |

| Datasheet | 0.065 | 0.089 | 0.052 | -- |

| PV Technologies | PCE Obtained (%) | PCE in STC (%) | Average Tc (°C) |

|---|---|---|---|

| CIGS | 10.28 | 11.77 | 49.20 |

| CdTe | 8.26 | 11.10 | 48.17 |

| OPV | 3.60 | 4.18 | 48.39 |

| A-Si | 2.59 | 3.68 | 46.19 |

| CIGS | CdTe | A-Si | OPV | |

|---|---|---|---|---|

| Initial PCE (%) | 10.3 | 9.46 | 2.60 | 4.22 |

| Final PCE (%) | 10.0 | 7.15 | 2.40 | 3.36 |

| Losses (%) | 3.38 | 24.4 | 7.69 | 20.4 |

| Avg Tc (°C) | 54.7 | 53.1 | 52.1 | 52.85 |

| Avg RH (%) | 76.19 | |||

| Avg TA (°C) | 31.90 | |||

| CIGS | CdTe | A-Si | OPV | |

|---|---|---|---|---|

| Initial PCE (%) | 9.91 | 8.89 | 2.81% | 4.96 |

| Final PCE (%) | 9.48 | 7.26 | 2.6% | 3.45 |

| Losses (%) | 4.34 | 18.34 | 11.89 | 30.4 |

| Average Tc (°C) | 51.42 | 54.96 | 49.91 | 50.2 |

| Avg RH (%) | 66.86 | |||

| Avg TA (°C) | 27.53 | |||

| CIGS | CdTe | A-Si | OPV | |

|---|---|---|---|---|

| Initial PCE (%) | 8.85 | 8.85 | 2.60 | 4.40 |

| Final PCE (%) | 8.49 | 8.20 | 2.57 | 3.99 |

| Losses (%) | 4.04 | 0.36 | 1.15 | 9.32 |

| Average Tc (°C) | 44 | 44.7 | 35 | 48 |

| Avg RH (%) | 84.78 | |||

| Avg TA (°C) | 20.1 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-Deusa, S.J.; Gómez-García, C.A.; Velasco-Medina, J. A Platform for Outdoor Real-Time Characterization of Photovoltaic Technologies. Energies 2023, 16, 2907. https://doi.org/10.3390/en16062907

Martínez-Deusa SJ, Gómez-García CA, Velasco-Medina J. A Platform for Outdoor Real-Time Characterization of Photovoltaic Technologies. Energies. 2023; 16(6):2907. https://doi.org/10.3390/en16062907

Chicago/Turabian StyleMartínez-Deusa, Sammy J., Carlos A. Gómez-García, and Jaime Velasco-Medina. 2023. "A Platform for Outdoor Real-Time Characterization of Photovoltaic Technologies" Energies 16, no. 6: 2907. https://doi.org/10.3390/en16062907