Experimental Study on the Sweep Law of CO2 Miscible Flooding in Heterogeneous Reservoir in Jilin

Abstract

:1. Introduction

2. Experimental Equipment and Methods

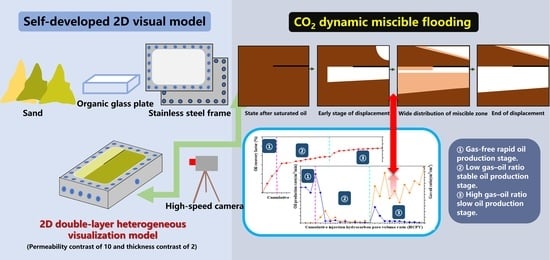

2.1. Model Design

2.2. Experimental System

2.3. Experimental Scheme

2.4. Experimental Materials and Procedures

- (1)

- The model was vacuumized for more than 6 h.

- (2)

- The simulated oil was injected from the bottom of the model. The oil was saturated at a constant speed and then at a constant pressure, and the saturation time was more than 24 h.

- (3)

- Control the back pressure to 8.5 MPa, inject CO2 at a constant pressure of 9.5 MPa from the injection side of the model, control the pressure difference to be about 1 MPa, and carry out oil at the production side.

- (4)

- During the entire displacement process, the displacement process was photographed and recorded at a non-uniform time interval of every 5–120 s. Measure the produced volume of simulated oil and CO2 at certain time intervals.

- (5)

- By visualizing the dynamic displacement process and the degree of oil and gas recovery, it was judged that when the gas–oil ratio was maintained at a high level or no more oil was produced, the experiment was terminated.

3. Experimental Results and Analysis

3.1. CO2 Dynamic Miscible Flooding

3.1.1. Migration Characteristics of Oil–Gas Interface

3.1.2. Distribution Characteristics of Miscible Zone

3.2. Oil Displacement Effect of CO2 Miscible Flooding

4. Conclusions

- (1)

- Under the combined influence of internal and external control factors, which included the reservoir thickness, permeability, and injection-production mode, the gas absorption capacity of the high-permeability layer was much greater than that of the low-permeability layer. This directly affected the sweep area and remaining oil distribution of the two layers.

- (2)

- The gas absorption capacity of the reservoir and gravitational differentiation were the key factors affecting the migration and variation of the oil–gas interface, and the miscible mass transfer and displacement power were the main factors affecting the formation and distribution characteristics of miscible zone.

- (3)

- The entire displacement process of the CO2 miscible flooding could be divided into three stages: gas-free rapid oil production, low gas–oil ratio stable oil production, and high gas–oil ratio slow oil production. The process from the CO2 injection to gas breakthrough was the stage of rapid oil production without gas, which was dominated by the displacement. The stage of stable oil production with a low gas–oil ratio occurred from the gas breakthrough to before the increase of oil production rate, it was jointly affected by the displacement and miscible mass transfer. After the oil production rate increased, the stage of slow oil production with a high gas–oil ratio was dominated by the effect of CO2 carrying.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- China Mineral Resources Report. 2021: Ministry of Natural Resources, PRC; Geology Press: Beijing, China, 2021; ISBN 978-7-116-12858-3.

- Zhang, X.; Kou, G.; Wang, Z.; Zhang, H.; Zhang, G.S. Technical Discussion on Development Effects of CO2 Flooding in Jilin Extra-Low Permeability Reservoir. Drill. Prod. Technol. 2019, 42, 64–67. [Google Scholar]

- Qi, Y.D.; Lei, Q.; Yu, R.Z.; Yan, J.; Liu, X.W.; Zhan, J.F. Analysis on factors influencing development effect of extra-ultra low permeability sandstone reservoirs. J. China Univ. Pet. (Ed. Nat. Ence) 2013, 37, 89–94. [Google Scholar]

- Lou, Y.; Yang, S.; Zhang, X.; Yu, Y.; Yin, D.; Li, M.; Wen, B. Experimental research on CO2 miscible flooding by advanced gas injection in low permeability reservoir-case of H79 block, Jilin oilfield. Pet. Geol. Recovery Effic. 2012, 19, 78–80. [Google Scholar] [CrossRef]

- Li, Y. Technical advancement and prospect for CO2 flooding enhanced oil recovery in low permeability reservoirs. Pet. Geol. Recovery Effic. 2020, 27, 1–10. [Google Scholar] [CrossRef]

- Wang, S.-T.; Tan, J.-L.; Lei, X.-H.; Shi, H.-X.; Tang, Z.-W. CO2 flooding technology for low pereability sandstone reservoir of Changqing oilfield. Int. Field Explor. Dev. Conf. 2018, 2018, 2542–2553. [Google Scholar]

- Yu, H.-W.; Yang, S.-Y.; Li, S.; Yang, Y.Z. Rules of Water Cut Variation in Low Permeability Oil Reservoir CO2 Flooding Process. J. Jilin Univ. (Earth Sci. Ed.) 2011, 41, 1028–1032. [Google Scholar] [CrossRef]

- Liu, F.; Yue, P.; Wang, Q.; Yu, G.; Zhou, J.; Wang, X.; Fang, Q.; Li, X. Experimental Study of Oil Displacement and Gas Channeling during CO2 Flooding in Ultra—Low Permeability Oil Reservoir. Energies 2022, 15, 5119. [Google Scholar] [CrossRef]

- Qian, K.; Yang, S.L.; Dou, H.; Zhang, J. Microscopic Characteristics of Oil Displacement with Different CO2 Injection Modes in Extra-Low Permeability Reservoirs. Xinjiang Pet. Geol. 2020, 41, 204–208. [Google Scholar]

- Wang, X.; Wang, L.; Xia, Z.; Shi, F. Microscopic mechanism of oil displacement under different CO2 injection modes in tight oil reservoirs. China Encepaper 2018, 13, 1754–1758. [Google Scholar]

- Wang, J.; Liu, Y.; Jiang, R.; Guan, C. 2-D physical modeling of water coning of horizontal well production in bottom water driving reservoirs. Pet. Explor. Dev. 2007, 5, 590–593. [Google Scholar]

- Qian, C.; Liu, Y.; Chi, X.; Zhou, X.; Luo, F. Physical Simulation Researches on the Water Cresting Constraint of the Horizontal Wells in Bottom-Water-Driven Oil Reservoir. Pet. Geol. Oilfield Dev. Daqing 2012, 31, 5. [Google Scholar]

- Huang, S.; Zeng, B.; Zhao, F.; Cheng, L.; Du, B. Water Breakthrough Shape Description of Horizontal Wells in Bottom-Water Reservoir. Math. Probl. Eng. 2014, 2014, 460896. [Google Scholar] [CrossRef]

- Li, B.; Liu, K. Visualization Study of Anti-water Coning Using Foam. Int. Field Explor. Dev. Conf. 2017, 2017, 1508–1514. [Google Scholar]

- Liu, Y.; Lu, J.; Wang, J.; Gao, J.; Li, Y. Physical modeling of in-depth fluid diversion by “gel dam” placed with a horizontal well. Pet. Explor. Dev. 2011, 38, 332–335. [Google Scholar]

- Xu, K.; Liu, W.; Guo, Y.; Yan, W.; Luo, L.; Gou, F.; Zhang, C. Experimental Study of Profile Control with Gel-dam. Sci. Technol. Eng. 2015, 15, 187–190. [Google Scholar]

- Qin, J.; Zhang, K.; Chen, X. Mechanism of the CO2 flooding as reservoirs containing high water. Acta Pet. Sin. 2010, 31, 797–800. [Google Scholar]

- Guo, X. Study on microscopic migration characteristics of heavy oil by CO2 flooding at high temperature and high pressure. Pet. Geol. Recovery Effic. 2019, 26, 99–104. [Google Scholar] [CrossRef]

- Yu, H.; Wang, L.; Zhou, D.; Wang, F.; Li, S.; Li, J.; Chen, X.; Cao, A.; Han, H. Experimental Study on Sweep Characteristics of Gas Gravity Drainage in the Interlayer Oil Reservoir. Front. Energy Res. 2021, 9, 660. [Google Scholar] [CrossRef]

- Jian, G.; Yang, S.; Li, J.; Wang, H.; Zhou, T. Main Controlling Factors of the CO2 Injectivity for Jilin Daqingzi Oilfifld. Pet. Geol. Oilfield Dev. Daqing 2016, 35, 128–131. [Google Scholar]

| State | 0 min | 1 min | 2 min | 20 min | 24 min | 34 min | 74 min | 164 min | 344 min | 358 min | 468 min |

|---|---|---|---|---|---|---|---|---|---|---|---|

| The proportion of the sweep area in the high-permeability | 0% | 1.0% | 2.3% | 19.2% | 22.9% | 33.0% | 34.5% | 35.7% | 38.4% | 39.6% | 40.9% |

| The proportion of the sweep area in the low-permeability | 0% | 0% | 0% | 0.7% | 0.8% | 2.8% | 4.5% | 5.3% | 6.4% | 7.0% | 9.0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Yu, H.; Yang, Z.; Li, J.; Chen, X.; Ma, L. Experimental Study on the Sweep Law of CO2 Miscible Flooding in Heterogeneous Reservoir in Jilin. Energies 2022, 15, 5755. https://doi.org/10.3390/en15155755

Li W, Yu H, Yang Z, Li J, Chen X, Ma L. Experimental Study on the Sweep Law of CO2 Miscible Flooding in Heterogeneous Reservoir in Jilin. Energies. 2022; 15(15):5755. https://doi.org/10.3390/en15155755

Chicago/Turabian StyleLi, Wen, Hongwei Yu, Zhengming Yang, Jinlong Li, Xinliang Chen, and Longfei Ma. 2022. "Experimental Study on the Sweep Law of CO2 Miscible Flooding in Heterogeneous Reservoir in Jilin" Energies 15, no. 15: 5755. https://doi.org/10.3390/en15155755