Schmitt et al. [

17] used numerical simulation to estimate the fuel efficiency of future vehicles. Their approach was to represent the fleet by some vehicle categories, 26 in total, and evaluate the total fuel consumption in two scenarios by comparing it to the baseline. By using some modifications in the technological factor to improve the FE, the following values can be achieved: approximately 9% to 17% of total fuel consumption reductions, which represent a decline in GHG emissions by 9% to 20% and 0.9 to 1.8 million hectares of land spared for other uses. Assumptions for achieving these numbers were as follows: subcompact and compact vehicles would represent approximately 60% of the fleet in 2030 compared to 45% in 2007. Incremental efficiency gains would be 15%. Drag and rolling coefficients would be reduced by 15% and 20%. Moreover, there would be a weight reduction by 10% or 20% in each category. Estimated travel per vehicle would remain constant. As was reported in [

6], although the drag coefficient reduces slightly over time, the frontal area continues increasing as vehicles become larger. Moreover, the sales of subcompact and compact declined steadily from 75% in 2000 to 35% in 2020. In addition, a 1.0 L model year (MY) in 2020 is significantly different from one in 2000 because of improvements in technology and engine downsizing, as engineers can extract more performance today for the same level of power than in the past [

4].

From the point of view of policymakers, De Melo et al. [

20] argued about the necessity of mandatory fuel economy standards (MFES), in line with the practices established in the United States, European Union, Japan, China, South Korea, Canada, and Mexico. An extensive discussion about those standards is available in [

21]; for an abridged version in English, refer to [

22], which focuses on the Brazilian history.

Their method [

20] was to estimate the improvements in efficiency exceeding baseline by the implementation of MFES. The average fuel efficiencies for compact and subcompact vehicles were approximately 1.85 MJ/km and 1.66 MJ/km, respectively, in 2017 (MJ/km is obtained by dividing the heating value of fuel in MJ/L by the fuel economy in km/L). The combined market share for these two classes was 65% and remained constant until 2035, the final year of the projections. The MFES was modeled as step-wise improvements by increasing the efficiency by 0.05 MJ/km and 0.08 MJ/km every four years. The results showed potential and avoided emissions of 62 Gg of CO

2 compared to the baseline. In reality, the average values for subcompact (19 models) and compact (78 models) in 2020, according to [

23], were 1.49 MJ/km and 1.67 MJ/km, which are close to the projected values. Nevertheless, the importance of the article is its reduction perspective. Unfortunately, the market shares of both classes reduced and reached 35% in 2020.

De Salvo Jr. et al. [

27,

28] conducted extensive analyses of engine technology impacts on energy efficiency first for a single year, 2017, and subsequently, compared the evolution over the years 2013, 2015, and 2017. Based on the official labeling program [

23], which has published FE for selected LDVs since 2009, they found that the overall efficiency improved by 3.5% from 2013 to 2017. The same observation can be obtained by dividing vehicle categories. Both papers further offer a review of engine technologies, quantify their impacts on efficiency, and trace their diffusion. The analysis focused on the models available in the market in that year; thus, those studies were not concerned with possible sales-weighted effects, such as consumers shifting preference toward a larger class of vehicles over time. However, even if efficiency improves on a class-by-class basis, this sales shift can impact overall efficiency, and Brazilians are showing a tendency to buy larger vehicles, which is discussed in

Section 4.4.

Estimating Technological Progress and Trade-Offs

The United States’ Environmental Protection Agency (EPA) publishes vehicle data, as well as sales-weighted averages, going back to 1975. An efficiency metric, ton.mpg, is published as well. Because this metric fails to account for performance improvements and mass efficiency due to lightweight materials, studies based on this data-set tried to establish these efficiency and performance trade-offs [

29,

30]. The main vehicle features that offset efficiency gains from the use of energy-saving technologies are more performance, which can be modelled as either more torque, horsepower or faster acceleration, which tend to be highly correlated, and more weight, due to increases in size, on-board features, and/or more safety. Mackenzie estimates that features added 223 kg to a vehicle in 2010. Among these, 28% are related to safety, 11% for emission control, and 61% for comfort and convenience [

4]. Lutsey and Sperling [

29] considered that ton.mpg was insufficient as it does not account for improvements in drag and rolling coefficients or the deployment of drivetrain efficiency technologies. They defined engine and drivetrain efficiency relative to vehicle characteristics, such as mass, acceleration, drag coefficient, frontal area, and tire rolling resistance. Combined with FE data, they estimated the elasticities for the variables mentioned via regression analysis. Thus, it was subsequently possible to estimate trade-offs between efficiency, performance, and size. The FE for cars and light trucks could be 12% higher in 2004 compared with that in 1987 if all technological improvements were directed toward more efficiency. Actual values were 2% higher for LDVs and 3% lower for light trucks.

An and DeCicco [

30] identified the same problem with ton.mpg as Lutsey and Sperling did, while using different vehicle attributes for analysis. Consequently, they developed a performance index that could capture trade-offs between size, performance, and FE. Equation (

1) presents the performance-size FE index (

) for light-duty vehicles. The term

is the horse-power,

is the weight in (lb),

is the engine consumption in miles per gallons, and

is the interior volume in cubic feet.

Their results [

30] indicate that

increased linearly from 1977 to 2005. Another inference was that no FE gains were realized in the period by keeping size and performance fixed, and a warn was made for prospective studies to consider this important fact.

Figure 1a,b illustrates these tendencies for the Brazilian market. As with ton.mpg, these metrics will help dissect what happened to the LDV market in Brazil, although the method was not employed here. The

for Brazil behaved better than ton.mpg. Apart from a slight dip in the beginning of the 1990s, the values increased constantly. Performance (P, in blue) reached a peak between 1993 and 1994, declined to a bottom in 1999, and then improved constantly. Herein, size (S, in purple) was measured, length × height × width, instead of interior volume, which decreased in the 1990s before increasing steadily. The FE (F, in red) decreased in this period, discussed in detail in

Section 4, as the Brazilian market changed significantly.

Bandivadekar [

31] further expanded on the rationale behind

proposing the Emphasis on Reducing Fuel Consumption (

) according to Equation (

2). This simple concept allows the illustration of the magnitude of these trade-offs. A generic gasoline ICE 2035 model with 0% ERFC would see an increase in its power-to-weight ratio (HP/WT, in horsepower and lbs) from 0.059 to 0.087 (47.5%), with time to accelerate from 0 to 100 km/h reduced from 8.7 to 6.4 s while maintaining fuel consumption at 8.1 L/100 km. In contrast, if the power-to-weigh ratio and acceleration remained at 2008 levels (i.e., a 100% ERFC), FE would reach 5.5 L/100 km, which is a 47.3% reduction. From a GHG emissions perspective, a 35% reduction from a No Change scenario would be possible by 2035. However, “all current trends run counter to the required changes”. Note that

does not need to stop at 100% as performance could reduce below baseline grades, thus reaching even more significant improvements in the FE.

According to Mackenzie [

4], there are two drawbacks to An and DeCicco’s approach. First, acceleration, and not the power-to-weight ratio, should be the preferred performance measure. Second, and most importantly, their approach assumes a 1:1:1 trade-off between size, power-to-weight ratio, and FE with no theoretical reason.

Knittel [

3], which is extensively cited in this study, estimated that when all other parameters are equal, a 10% reduction in weight produced a 4.19% increase in FE. and a 10% increase in horsepower decreased FE by 2.62%. Thus, the 1:1:1 trade-off does not occur. Torque effects were not statistically significant. The econometric model used to reach these numbers is discussed in detail in

Section 3. Another important conclusion was found: average FE could have increased by approximately 60% in the period 1980–2006 if vehicle attributes, such as weight, horsepower, and torque, were maintained at the 1980 levels. Actual realized improvements were 15%. This fact may raise questions about incentives to consumption trends, such as for household appliances [

32]. Some of these are as follows: what kind of vehicles are suitable for urban, highway, and other different applications? Which policies may the exergy analysis contribute to the better end-use of exergy, considering technological gains and security parameters?

Mackenzie [

4] followed this approach and modeled fuel consumption in gallons per mile (gpm) as a function of inertia weight (IWT) in kg, acceleration from 0 to 97 km/h (Z97), and other vehicle parameters. The authors used eight econometric models in their analyses and accounted for weight reductions that would have happened if not for changes in size, features, and functionality. This potential mass reduction was 650 kg or 40% for the average vehicle from 1975 to 2009 [

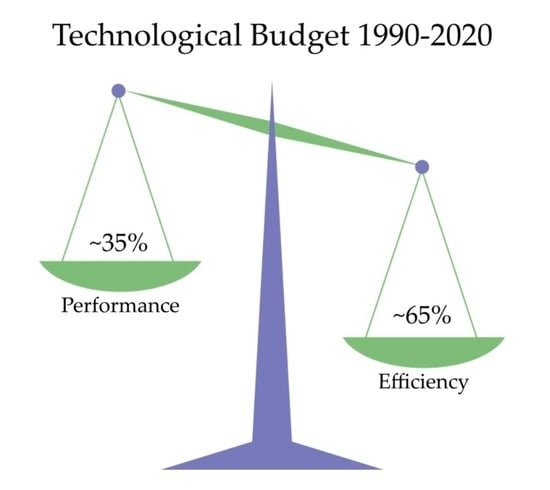

33]. Additionally, they found that a 10% reduction in inertia weight resulted in a 6.9% decrease in fuel consumption for the same period. Furthermore, a 10% improvement in acceleration resulted in a 4.4% increase in fuel consumption without modifications in other variables. Moreover, it was estimated that per-mile fuel consumption could have been reduced by about 70% (3.4% per year) if not for improvements in acceleration, new features, and functionalities. The rate of technological progress was not uniform, averaging 5% and 2.1% per year during the periods 1975–1990 and 1990–2009, respectively.

Subsequently, an adapted version of Bandivadekar’s ERFC was used to calculate values for the period 1975–2009. The evolution follows a “V-shaped” curve, with ERFC exceeding 100% from 1975 to 1980 (when performance was reduced to increase efficiency), −25% in 1995–2000 (when performance improvements outpaced technological capability; thus, efficiency was reduced), before rebounding to 75% in 2005–2009 (a value between 0 and 1 implies both performance and efficiency improved simultaneously, but at compromised levels).

Hu and Chen [

34] applied Knittel and Mackenzie’s method for the European market from 1975 to 2015. They found that the rates of technological progress were slightly lower than those in the USA. However, the most interesting finding was that engine size, weight, and power were actually reduced by 20%, 5%, and 2% respectively, from 2006 to 2015. Although torque and acceleration performance increased by 11% and 7%, respectively, these developments, combined with the increased penetration of diesel vehicles, increased FE by 32% in the period. This shift was also observed in the Swedish market, where 33% of technological development was used for improved FE in 1975–2007 and 77% in 2007–2010 [

35]. Kwon [

36] controlled the engine size for the Great Britain market from 1979 to 2000. FE improved by 0.9% per year but could have been 1.1% if not for the increased average engine capacity. Furthermore, performance offsetting better technological gains was observed in the Dutch market from 1990 to 1997 because of higher engine capacity and more weight [

37]. J. Wu et al. [

38] applied Knittel’s approach to the Chinese market from 2010 to 2019 and differentiated between indigenous, joint-venture, and foreign vehicle manufacturers. They found rates of yearly technological progress between 3.1% and 3.9%.

Drawbacks of this econometric approach are that it assumes constant elasticities and trade-offs for the entire period studied, which usually spans a few decades.This may not necessarily be the case, according to Moskalik [

39]. By modeling individual engines, Moskalik found a general trend toward lower elasticity values for the trade-off between acceleration and fuel economy over time. This is because modern engines have broader efficiency islands. Another drawback is that this approach relies on FE from standardized tests, which could differ significantly from real-world conditions. Craglia and Cullen [

40] used real-world FE data and further divided regression analysis on the basis of powertrain, petrol, diesel, and hybrid engines in Britain from 2001 to 2018. They found different elasticities for different powertrains by justifying the division. Additionally, they found that 60% of potential efficiency gains were offset by increasing size and power.