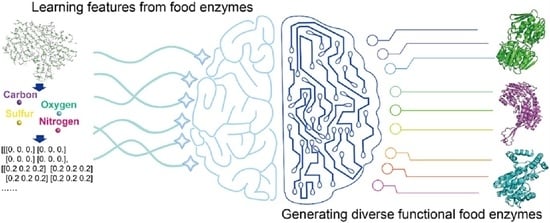

Possibilities of Using De Novo Design for Generating Diverse Functional Food Enzymes

Abstract

:1. Introduction

2. Diverse Functions of Food Enzymes

3. Challenges for Food Enzyme Engineering

4. De Novo Design Inspired by Highly Accurate Protein Modeling

4.1. Template-Based Protein Modeling

4.2. Non-Template-Based Protein Modeling

5. De Novo Design of Food Enzymes

5.1. Current Solutions

5.2. AI-Based De Novo Design Techniques

5.2.1. Protein Hallucination

5.2.2. RFDesign

5.2.3. ProteinMPNN

5.2.4. DenseCPD

5.2.5. Unsupervised Learning Methods

6. Limitations of De Novo Design Techniques and Opportunities for Food Enzyme Engineering

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Consortium, T.U. UniProt: The universal protein knowledgebase in 2021. Nucleic Acids Res. 2020, 49, D480–D489. [Google Scholar] [CrossRef]

- Bileschi, M.L.; Belanger, D.; Bryant, D.H.; Sanderson, T.; Carter, B.; Sculley, D.; Bateman, A.; DePristo, M.A.; Colwell, L.J. Using deep learning to annotate the protein universe. Nat. Biotechnol. 2022, 40, 932–937. [Google Scholar] [CrossRef]

- Lee, J.; Chen, W.-H.; Park, Y.-K. Recent achievements in platform chemical production from food waste. Bioresour. Technol. 2022, 366, 128204. [Google Scholar] [CrossRef]

- Reshmy, R.; Philip, E.; Sirohi, R.; Tarafdar, A.; Arun, K.B.; Madhavan, A.; Binod, P.; Kumar Awasthi, M.; Varjani, S.; Szakacs, G.; et al. Nanobiocatalysts: Advancements and applications in enzyme technology. Bioresour. Technol. 2021, 337, 125491. [Google Scholar] [CrossRef]

- Collados, A.; Conversa, V.; Fombellida, M.; Rozas, S.; Kim, J.H.; Arboleya, J.-C.; Román, M.; Perezábad, L. Applying food enzymes in the kitchen. Int. J. Gastron. Food Sci. 2020, 21, 100212. [Google Scholar] [CrossRef]

- Dixit, M.; Chhabra, D.; Shukla, P. Optimization of endoglucanase-lipase-amylase enzyme consortium from Thermomyces lanuginosus VAPS25 using Multi-Objective genetic algorithm and their bio-deinking applications. Bioresour. Technol. 2023, 370, 128467. [Google Scholar] [CrossRef]

- Katsila, T.; Siskos, A.P.; Tamvakopoulos, C. Peptide and protein drugs: The study of their metabolism and catabolism by mass spectrometry. Mass Spectrom. Rev. 2012, 31, 110–133. [Google Scholar] [CrossRef] [PubMed]

- Gagner, J.E.; Kim, W.; Chaikof, E.L. Designing protein-based biomaterials for medical applications. Acta Biomater. 2014, 10, 1542–1557. [Google Scholar] [CrossRef] [PubMed]

- Ramli, A.N.M.; Hong, P.K.; Abdul Manas, N.H.; Wan Azelee, N.I. Chapter 25—An overview of enzyme technology used in food industry. In Value-Addition in Food Products and Processing Through Enzyme Technology; Kuddus, M., Aguilar, C.N., Eds.; Academic Press: Cambridge, MA, USA, 2022; pp. 333–345. [Google Scholar] [CrossRef]

- Fernandes, P. Enzymes in food processing: A condensed overview on strategies for better biocatalysts. Enzym. Res. 2010, 2010, 862537. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gagaoua, M.; Dib, A.L.; Lakhdara, N.; Lamri, M.; Botineştean, C.; Lorenzo, J.M. Artificial meat tenderization using plant cysteine proteases. Curr. Opin. Food Sci. 2021, 38, 177–188. [Google Scholar] [CrossRef]

- Wang, T.; Qin, G.-X.; Sun, Z.-W.; Zhao, Y. Advances of research on glycinin and β-conglycinin: A review of two major soybean allergenic proteins. Crit. Rev. Food Sci. Nutr. 2014, 54, 850–862. [Google Scholar] [CrossRef]

- Lee, K.D.; Lo, C.G.; Warthesen, J.J. Removal of bitterness from the bitter peptides extracted from cheddar cheese with peptidases from lactococcus lactis ssp. cremoris SK111. J. Dairy Sci. 1996, 79, 1521–1528. [Google Scholar] [CrossRef]

- Borchers, A.; Teuber, S.S.; Keen, C.L.; Gershwin, M.E. Food safety. Clin. Rev. Allergy Immunol. 2010, 39, 95–141. [Google Scholar] [CrossRef] [PubMed]

- Enzymes market size to reach $17.8 bn in 2028, industry trend—Rising demand for high-quality pharmaceutical, food & beverage and personal care products. Focus Catal. 2022, 2022, 2–3. [CrossRef]

- Global industrial biotechnology market report 2022: Development of new and improved enzymes and other biocatalysts key for future developments. Focus Catal. 2022, 2022, 2–3. [CrossRef]

- Famiglietti, M.; Mirpoor, S.F.; Giosafatto, C.V.L.; Mariniello, L. Enzyme assisted food processing. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Madhavan, A.; Arun, K.B.; Binod, P.; Sirohi, R.; Tarafdar, A.; Reshmy, R.; Kumar Awasthi, M.; Sindhu, R. Design of novel enzyme biocatalysts for industrial bioprocess: Harnessing the power of protein engineering, high throughput screening and synthetic biology. Bioresour. Technol. 2021, 325, 124617. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, P.; Fernandes, P.A.; Ramos, M.J. Modern computational methods for rational enzyme engineering. Chem Catal. 2022, 2, 2481–2498. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, H.; Wold, E.A.; Zhou, J. 2.13—Small-molecule inhibitors of protein–protein interactions. In Comprehensive Medicinal Chemistry III; Chackalamannil, S., Rotella, D., Ward, S.E., Eds.; Elsevier: Oxford, UK, 2017; pp. 329–353. [Google Scholar] [CrossRef] [Green Version]

- Park, H.; Bradley, P.; Greisen, P.; Liu, Y.; Mulligan, V.K.; Kim, D.E.; Baker, D.; DiMaio, F. Simultaneous optimization of biomolecular energy functions on features from small molecules and macromolecules. J. Chem. Theory Comput. 2016, 12, 6201–6212. [Google Scholar] [CrossRef]

- Jumper, J.; Evans, R.; Pritzel, A.; Green, T.; Figurnov, M.; Ronneberger, O.; Tunyasuvunakool, K.; Bates, R.; Žídek, A.; Potapenko, A.; et al. Highly accurate protein structure prediction with AlphaFold. Nature 2021, 596, 583–589. [Google Scholar] [CrossRef]

- Daniel, L.; Aikaterini, A.; Simhadri, V.L.; Katagiri, N.H.; Wojciech, J.; Sauna, Z.E.; Chava, K.S. Recent advances in (therapeutic protein) drug development. F1000Research 2017, 6, 113. [Google Scholar] [CrossRef]

- Setiawan, D.; Brender, J.; Zhang, Y. Recent advances in automated protein design and its future challenges. Expert Opin. Drug Discov. 2018, 13, 587–604. [Google Scholar] [CrossRef]

- Dimitrov, D.S. Therapeutic proteins. In Therapeutic Proteins: Methods and Protocols; Voynov, V., Caravella, J.A., Eds.; Humana Press: Totowa, NJ, USA, 2012; pp. 1–26. [Google Scholar] [CrossRef]

- Kellogg, E.H.; Leaver-Fay, A.; Baker, D. Role of conformational sampling in computing mutation-induced changes in protein structure and stability. Proteins: Struct. Funct. Bioinform. 2011, 79, 830–838. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Du, J.; Zhao, B.; Wang, H.; Rao, S.; Du, G.; Zhou, J.; Chen, J.; Liu, S. Significantly improving the thermostability and catalytic efficiency of Streptomyces mobaraenesis transglutaminase through combined rational design. J. Agric. Food Chem. 2021, 69, 15268–15278. [Google Scholar] [CrossRef] [PubMed]

- Khersonsky, O.; Lipsh, R.; Avizemer, Z.; Ashani, Y.; Goldsmith, M.; Leader, H.; Dym, O.; Rogotner, S.; Trudeau, D.L.; Prilusky, J.; et al. Automated design of efficient and functionally diverse enzyme repertoires. Mol. Cell 2018, 72, 178–186.e175. [Google Scholar] [CrossRef] [PubMed]

- Langan, R.A.; Boyken, S.E.; Ng, A.H.; Samson, J.A.; Dods, G.; Westbrook, A.M.; Nguyen, T.H.; Lajoie, M.J.; Chen, Z.; Berger, S.; et al. De novo design of bioactive protein switches. Nature 2019, 572, 205–210. [Google Scholar] [CrossRef] [PubMed]

- Basanta, B.; Bick, M.J.; Bera, A.K.; Norn, C.; Chow, C.M.; Carter, L.P.; Goreshnik, I.; Dimaio, F.; Baker, D. An enumerative algorithm for de novo design of proteins with diverse pocket structures. Proc. Natl. Acad. Sci. USA 2020, 117, 22135–22145. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Lisanza, S.; Juergens, D.; Tischer, D.; Watson, J.L.; Castro, K.M.; Ragotte, R.; Saragovi, A.; Milles, L.F.; Baek, M.; et al. Scaffolding protein functional sites using deep learning. Science 2022, 377, 387–394. [Google Scholar] [CrossRef] [PubMed]

- Anishchenko, I.; Pellock, S.J.; Chidyausiku, T.M.; Ramelot, T.A.; Ovchinnikov, S.; Hao, J.; Bafna, K.; Norn, C.; Kang, A.; Bera, A.K.; et al. De novo protein design by deep network hallucination. Nature 2021, 600, 547–552. [Google Scholar] [CrossRef]

- Dauparas, J.; Anishchenko, I.; Bennett, N.; Bai, H.; Ragotte, R.J.; Milles, L.F.; Wicky, B.I.M.; Courbet, A.; de Haas, R.J.; Bethel, N.; et al. Robust deep learning–based protein sequence design using ProteinMPNN. Science 2022, 378, 49–56. [Google Scholar] [CrossRef]

- Harteveld, Z.; Bonet, J.; Rosset, S.; Yang, C.; Sesterhenn, F.; Correia, B.E. A generic framework for hierarchical de novo protein design. Proc. Natl. Acad. Sci. USA 2022, 119, e2206111119. [Google Scholar] [CrossRef]

- Repecka, D.; Jauniskis, V.; Karpus, L.; Rembeza, E.; Rokaitis, I.; Zrimec, J.; Poviloniene, S.; Laurynenas, A.; Viknander, S.; Abuajwa, W.; et al. Expanding functional protein sequence spaces using generative adversarial networks. Nat. Mach. Intell. 2021, 3, 324–333. [Google Scholar] [CrossRef]

- Strop, P. Versatility of microbial transglutaminase. Bioconj. Chem. 2014, 25, 855–862. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, M.K.; Wong, J.W.C.; Kumar, S.; Awasthi, S.K.; Wang, Q.; Wang, M.; Ren, X.; Zhao, J.; Chen, H.; Zhang, Z. Biodegradation of food waste using microbial cultures producing thermostable α-amylase and cellulase under different pH and temperature. Bioresour. Technol. 2018, 248, 160–170. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Chen, Y.; Chen, J. The starch hydrolysis and aroma retention caused by salivary α-amylase during oral processing of food. Curr. Opin. Food Sci. 2022, 43, 237–245. [Google Scholar] [CrossRef]

- Shimizu, M.; Sawashita, N.; Morimatsu, F.; Ichikawa, J.; Taguchi, Y.; Ijiri, Y.; Yamamoto, J. Antithrombotic papain-hydrolyzed peptides isolated from pork meat. Thromb. Res. 2009, 123, 753–757. [Google Scholar] [CrossRef]

- Sutay Kocabaş, D.; Lyne, J.; Ustunol, Z. Hydrolytic enzymes in the dairy industry: Applications, market and future perspectives. Trends Food Sci. Technol. 2022, 119, 467–475. [Google Scholar] [CrossRef]

- Salgado, C.A.; dos Santos, C.I.A.; Vanetti, M.C.D. Microbial lipases: Propitious biocatalysts for the food industry. Food Biosci. 2022, 45, 101509. [Google Scholar] [CrossRef]

- Morata, A.; Vejarano, R.; Ridolfi, G.; Benito, S.; Palomero, F.; Uthurry, C.; Tesfaye, W.; González, C.; Suárez-Lepe, J.A. Reduction of 4-ethylphenol production in red wines using HCDC+ yeasts and cinnamyl esterases. Enzym. Microb. Technol. 2013, 52, 99–104. [Google Scholar] [CrossRef]

- Kyriakidis, N.B. Use of pectinesterase for detection of hydrocolloids addition in natural orange juice. Food Hydrocoll. 1999, 13, 497–500. [Google Scholar] [CrossRef]

- Ge, L.; Zhao, Y.-s.; Mo, T.; Li, J.-r.; Li, P. Immobilization of glucose oxidase in electrospun nanofibrous membranes for food preservation. Food Control 2012, 26, 188–193. [Google Scholar] [CrossRef]

- Li, X.; Li, S.; Liang, X.; McClements, D.J.; Liu, X.; Liu, F. Applications of oxidases in modification of food molecules and colloidal systems: Laccase, peroxidase and tyrosinase. Trends Food Sci. Technol. 2020, 103, 78–93. [Google Scholar] [CrossRef]

- Yamaguchi, S.; Jeenes, D.J.; Archer, D.B. Protein-glutaminase from Chryseobacterium proteolyticum, an enzyme that deamidates glutaminyl residues in proteins. Eur. J. Biochem. 2001, 268, 1410–1421. [Google Scholar] [CrossRef] [PubMed]

- Caruso, M.A.; Piermaria, J.A.; Abraham, A.G.; Medrano, M. β-glucans obtained from beer spent yeasts as functional food grade additive: Focus on biological activity. Food Hydrocoll. 2022, 133, 107963. [Google Scholar] [CrossRef]

- Paziak-Domańska, B.; Bogusławska, E.; Więckowska-Szakiel, M.; Kotłowski, R.; Różalska, B.; Chmiela, M.; Kur, J.; Dąbrowski, W.; Rudnicka, W. Evaluation of the API test, phosphatidylinositol-specific phospholipase C activity and PCR method in identification of Listeria monocytogenes in meat foods. FEMS Microbiol. Lett. 1999, 171, 209–214. [Google Scholar] [CrossRef] [PubMed]

- Long, J.; Li, X.; Xue, L.; Xie, Z.; Jiao, A.; Bai, Y.; Zhou, X.; Chen, L.; Qiu, C.; Xu, X.; et al. Continuous hydrolysis of mango peel pectin for the production of antibacterial pectic oligosaccharides in packed-bed reactor using immobilized polygalacturonase. Food Biosci. 2022, 50, 102117. [Google Scholar] [CrossRef]

- Fernandes de Souza, H.; Aguiar Borges, L.; Dédalo Di Próspero Gonçalves, V.; Vitor dos Santos, J.; Sousa Bessa, M.; Fronja Carosia, M.; Vieira de Carvalho, M.; Viana Brandi, I.; Setsuko Kamimura, E. Recent advances in the application of xylanases in the food industry and production by actinobacteria: A review. Food Res. Int. 2022, 162, 112103. [Google Scholar] [CrossRef]

- Kim, Y.-L.; Mun, S.; Park, K.-H.; Shim, J.-Y.; Kim, Y.-R. Physicochemical functionality of 4-α-glucanotransferase-treated rice flour in food application. Int. J. Biol. Macromol. 2013, 60, 422–426. [Google Scholar] [CrossRef]

- Microbial rennin with enhanced milk-clotting activity. Trends Food Sci. Technol. 1997, 8, 177. [CrossRef]

- Kirimura, K.; Cao, W.; Onda, Y.; Yoshioka, I.; Ishii, Y. Selective and high-yield production of ethyl α-d-glucopyranoside by the α-glucosyl transfer enzyme of Xanthomonas campestris WU-9701 and glucose isomerase. J. Biosci. Bioeng. 2022, 134, 220–225. [Google Scholar] [CrossRef]

- Suzuki, K.; Nakamura, M.; Sato, N.; Futamura, K.; Matsunaga, K.; Yagami, A. Nattokinase, a subtilisin family serine protease, is a novel allergen contained in the traditional Japanese fermented food natto. Allergol. Int. 2022, in press. [Google Scholar] [CrossRef]

- Coutinho, T.C.; Tardioli, P.W.; Farinas, C.S. Phytase immobilization on hydroxyapatite nanoparticles improves its properties for use in animal feed. Appl. Biochem. Biotechnol. 2020, 190, 270–292. [Google Scholar] [CrossRef] [PubMed]

- Chiba, H.; Takahashi, N.; Sasaki, R. Enzymatic improvement of food flavor II. Removal of beany flavor from soybean products by aldehyde dehydrogenase. Agric. Biol. Chem. 1979, 43, 1883–1889. [Google Scholar] [CrossRef]

- Maheshwari, P.; Murphy, P.A.; Nikolov, Z.L. Characterization and application of porcine liver aldehyde oxidase in the off-flavor reduction of soy proteins. J. Agric. Food Chem. 1997, 45, 2488–2494. [Google Scholar] [CrossRef]

- Bornscheuer, U.T.; Huisman, G.W.; Kazlauskas, R.J.; Lutz, S.; Moore, J.C.; Robins, K. Engineering the third wave of biocatalysis. Nature 2012, 485, 185–194. [Google Scholar] [CrossRef]

- Wang, X.; Yang, P.; Zhao, B.; Liu, S. AI-assisted food enzymes design and engineering: A critical review. Syst. Microbiol. Biomanufacturing 2022, 3, 75–87. [Google Scholar] [CrossRef]

- Modarres, H.P.; Mofrad, M.R.; Sanati-Nezhad, A. Protein thermostability engineering. RSC Adv. 2016, 6, 115252–115270. [Google Scholar] [CrossRef]

- Buchardt, J.; Selvig, H.; Nielsen, P.F.; Johansen, N.L. Transglutaminase-mediated methods for site-selective modification of human growth hormone. Pept. Sci. 2010, 94, 229–235. [Google Scholar] [CrossRef]

- Tong, L.; Zheng, J.; Wang, X.; Wang, X.; Huang, H.; Yang, H.; Tu, T.; Wang, Y.; Bai, Y.; Yao, B.; et al. Improvement of thermostability and catalytic efficiency of glucoamylase from Talaromyces leycettanus JCM12802 via site-directed mutagenesis to enhance industrial saccharification applications. Biotechnol. Biofuels 2021, 14, 202. [Google Scholar] [CrossRef]

- Li, S.; Yang, Q.; Tang, B. Improving the thermostability and acid resistance of Rhizopus oryzae alpha-amylase by using multiple sequence alignment based site-directed mutagenesis. Biotechnol. Appl. Biochem. 2020, 67, 677–684. [Google Scholar] [CrossRef]

- Dotsenko, A.S.; Dotsenko, G.S.; Rozhkova, A.M.; Zorov, I.N.; Sinitsyn, A.P. Rational design and structure insights for thermostability improvement of Penicillium verruculosum Cel7A cellobiohydrolase. Biochimie 2020, 176, 103–109. [Google Scholar] [CrossRef]

- Ashraf, N.M.; Krishnagopal, A.; Hussain, A.; Kastner, D.; Sayed, A.M.M.; Mok, Y.-K.; Swaminathan, K.; Zeeshan, N. Engineering of serine protease for improved thermostability and catalytic activity using rational design. Int. J. Biol. Macromol. 2019, 126, 229–237. [Google Scholar] [CrossRef]

- Zhang, H.; Sang, J.; Zhang, Y.; Sun, T.; Liu, H.; Yue, R.; Zhang, J.; Wang, H.; Dai, Y.; Lu, F.; et al. Rational design of a Yarrowia lipolytica derived lipase for improved thermostability. Int. J. Biol. Macromol. 2019, 137, 1190–1198. [Google Scholar] [CrossRef]

- Aich, S.; Datta, S. Engineering of a highly thermostable endoglucanase from the GH7 family of Bipolaris sorokiniana for higher catalytic efficiency. Appl. Microbiol. Biotechnol. 2020, 104, 3935–3945. [Google Scholar] [CrossRef]

- Fakhravar, A.; Hesampour, A. Rational design-based engineering of a thermostable phytase by site-directed mutagenesis. Mol. Biol. Rep. 2018, 45, 2053–2061. [Google Scholar] [CrossRef]

- Jin, L.-Q.; Jin, Y.-T.; Zhang, J.-W.; Liu, Z.-Q.; Zheng, Y.-G. Enhanced catalytic efficiency and thermostability of glucose isomerase from Thermoanaerobacter ethanolicus via site-directed mutagenesis. Enzym. Microb. Technol. 2021, 152, 109931. [Google Scholar] [CrossRef]

- Li, Z.; Niu, C.; Yang, X.; Zheng, F.; Liu, C.; Wang, J.; Li, Q. Enhanced acidic resistance ability and catalytic properties of Bacillus 1,3-1,4-β-glucanases by sequence alignment and surface charge engineering. Int. J. Biol. Macromol. 2021, 192, 426–434. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Mathur, A.S.; Gupta, R.P.; Barrow, C.J.; Tuli, D.K.; Puri, M. Enzyme systems of thermophilic anaerobic bacteria for lignocellulosic biomass conversion. Int. J. Biol. Macromol. 2021, 168, 572–590. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, R.K.; Ullah, S.; Hoque, M.Z.; Ahmad, I.; Yang, Y.-H.; Bhatt, A.K.; Bhatia, S.K. Psychrophiles: A source of cold-adapted enzymes for energy efficient biotechnological industrial processes. J. Environ. Chem. Eng. 2021, 9, 104607. [Google Scholar] [CrossRef]

- Tiwari, M.K.; Singh, R.; Singh, R.K.; Kim, I.-W.; Lee, J.-K. Computational approaches for rational design of proteins with novel functionalities. Comput. Struct. Biotechnol. J. 2012, 2, e201204002. [Google Scholar] [CrossRef]

- Wu, J.; Bao, M.; Duan, X.; Zhou, P.; Chen, C.; Gao, J.; Cheng, S.; Zhuang, Q.; Zhao, Z. Developing a pathway-independent and full-autonomous global resource allocation strategy to dynamically switching phenotypic states. Nat. Commun. 2020, 11, 5521. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Yuan, L.; Lu, H.; Li, G.; Chen, Y.; Engqvist, M.K.M.; Kerkhoven, E.J.; Nielsen, J. Deep learning-based kcat prediction enables improved enzyme-constrained model reconstruction. Nat. Catal. 2022, 5, 662–672. [Google Scholar] [CrossRef]

- Paul, D.; Sanap, G.; Shenoy, S.; Kalyane, D.; Kalia, K.; Tekade, R.K. Artificial intelligence in drug discovery and development. Drug Discov. Today 2021, 26, 80–93. [Google Scholar] [CrossRef] [PubMed]

- Baek, M.; DiMaio, F.; Anishchenko, I.; Dauparas, J.; Ovchinnikov, S.; Lee, G.R.; Wang, J.; Cong, Q.; Kinch, L.N.; Schaeffer, R.D.; et al. Accurate prediction of protein structures and interactions using a three-track neural network. Science 2021, 373, 871–876. [Google Scholar] [CrossRef] [PubMed]

- Richter, F.; Leaver-Fay, A.; Khare, S.D.; Bjelic, S.; Baker, D. De novo enzyme design using Rosetta3. PloS ONE 2011, 6, e19230. [Google Scholar] [CrossRef]

- Chen, Q.; Wu, R. CNN is all you need. arXiv 2017, arXiv:1712.09662. [Google Scholar] [CrossRef]

- Sheng, W.; Sun, S.; Zhen, L.; Zhang, R.; Xu, J.; Avner, S. Accurate de novo prediction of protein contact map by ultra-deep learning model. PLoS Comput. Biol. 2017, 13, e1005324. [Google Scholar] [CrossRef] [Green Version]

- Ferruz, N.; Höcker, B. Controllable protein design with language models. Nat. Mach. Intell. 2022, 4, 521–532. [Google Scholar] [CrossRef]

- Castro, E.; Godavarthi, A.; Rubinfien, J.; Givechian, K.; Bhaskar, D.; Krishnaswamy, S. Transformer-based protein generation with regularized latent space optimization. Nat. Mach. Intell. 2022, 4, 840–851. [Google Scholar] [CrossRef]

- Kobe, B.; Guncar, G.; Buchholz, R.; Huber, T.; Maco, B.; Cowieson, N.; Martin, J.L.; Marfori, M.; Forwood, J.K. Crystallography and protein–protein interactions: Biological interfaces and crystal contacts. Biochem. Soc. Trans. 2008, 36, 1438–1441. [Google Scholar] [CrossRef]

- Tang, Y.; Schneider, W.M.; Shen, Y.; Raman, S.; Inouye, M.; Baker, D.; Roth, M.J.; Montelione, G.T. Fully automated high-quality NMR structure determination of small 2H-enriched proteins. J. Struct. Funct. Genom. 2010, 11, 223–232. [Google Scholar] [CrossRef]

- Nygaard, R.; Kim, J.; Mancia, F. Cryo-electron microscopy analysis of small membrane proteins. Curr. Opin. Struct. Biol. 2020, 64, 26–33. [Google Scholar] [CrossRef] [PubMed]

- Berman, H.M.; Westbrook, J.; Feng, Z.; Gilliland, G.; Bhat, T.N.; Weissig, H.; Shindyalov, I.N.; Bourne, P.E. The protein data bank. Nucleic Acids Res. 2000, 28, 235–242. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Zhang, Y. Protein structure and function prediction using I-TASSER. Curr. Protoc. Bioinform. 2015, 52, 5–8. [Google Scholar] [CrossRef] [PubMed]

- Webb, B.; Sali, A. Protein structure modeling with modeller. In Protein Structure Prediction; Kihara, D., Ed.; Springer: New York, NY, USA, 2014; pp. 1–15. [Google Scholar] [CrossRef]

- Pei, J. Multiple protein sequence alignment. Curr. Opin. Struct. Biol. 2008, 18, 382–386. [Google Scholar] [CrossRef]

- Waterhouse, A.; Bertoni, M.; Bienert, S.; Studer, G.; Tauriello, G.; Gumienny, R.; Heer, F.T.; de Beer, T.A.P.; Rempfer, C.; Bordoli, L.; et al. SWISS-MODEL: Homology modelling of protein structures and complexes. Nucleic Acids Res. 2018, 46, W296–W303. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Zheng, W.; Mortuza, S.M.; Li, Y.; Zhang, Y. DeepMSA: Constructing deep multiple sequence alignment to improve contact prediction and fold-recognition for distant-homology proteins. Bioinformatics 2019, 36, 2105–2112. [Google Scholar] [CrossRef]

- Du, T.; Liao, L.; Wu, C.H.; Sun, B. Prediction of residue-residue contact matrix for protein-protein interaction with Fisher score features and deep learning. Methods 2016, 110, 97–105. [Google Scholar] [CrossRef]

- Yin, R.; Feng, B.Y.; Varshney, A.; Pierce, B.G. Benchmarking AlphaFold for protein complex modeling reveals accuracy determinants. Protein Sci. 2022, 31, e4379. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, L.; Polosukhin, I. Attention is all you need. arXiv 2017, arXiv. [Google Scholar] [CrossRef]

- Bahdanau, D.; Cho, K.; Bengio, Y. Neural machine translation by jointly learning to align and translate. arXiv 2014, arXiv:1409.0473. [Google Scholar] [CrossRef]

- Leaver-Fay, A.; Snoeyink, J.; Kuhlman, B. On-the-Fly rotamer pair energy evaluation in protein design. In Bioinformatics Research and Applications; Springer: Berlin/Heidelberg, 2008; pp. 343–354. [Google Scholar]

- Haspel, N.; Tsai, C.-J.; Wolfson, H.; Nussinov, R. Reducing the computational complexity of protein folding via fragment folding and assembly. Protein Sci. 2003, 12, 1177–1187. [Google Scholar] [CrossRef]

- Onuchic, J.N.; Luthey-Schulten, Z.; Wolynes, P.G. Theory of protein folding: The energy landscape perspective. Annu. Rev. Phys. Chem. 1997, 48, 545–600. [Google Scholar] [CrossRef]

- Zhang, C.T.; Chou, K.C. Monte Carlo simulation studies on the prediction of protein folding types from amino acid composition. Biophys. J. 1992, 63, 1523–1529. [Google Scholar] [CrossRef]

- Osguthorpe, D.J. Ab initio protein folding. Curr. Opin. Struct. Biol. 2000, 10, 146–152. [Google Scholar] [CrossRef] [PubMed]

- Hansmann, U.H.E.; Okamoto, Y. New Monte Carlo algorithms for protein folding. Curr. Opin. Struct. Biol. 1999, 9, 177–183. [Google Scholar] [CrossRef] [PubMed]

- Ciemny, M.P.; Badaczewska-Dawid, A.E.; Pikuzinska, M.; Kolinski, A.; Kmiecik, S. Modeling of disordered protein structures using Monte Carlo simulations and knowledge-based statistical force fields. Int. J. Mol. Sci. 2019, 20, 606. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Anishchenko, I.; Park, H.; Peng, Z.; Ovchinnikov, S.; Baker, D. Improved protein structure prediction using predicted interresidue orientations. Proc. Natl. Acad. Sci. USA 2020, 117, 1496–1503. [Google Scholar] [CrossRef]

- Bo, C.; Dell’Acqua, F.; Deng, S.; Hsu, D.; Chaintreau, A. Biased programmers? Or biased data? A field experiment in operationalizing AI ethics. In Proceedings of the 21st ACM Conference on Economics and Computation, Budapest, Hungary, 13–17 July 2020. [Google Scholar]

- Lin, Z.; Akin, H.; Rao, R.; Hie, B.; Zhu, Z.; Lu, W.; Smetanin, N.; Verkuil, R.; Kabeli, O.; Shmueli, Y.; et al. Evolutionary-scale prediction of atomic level protein structure with a language model. bioRxiv 2022, 2022, 7. [Google Scholar] [CrossRef]

- Weissenow, K.; Heinzinger, M.; Rost, B. Protein language-model embeddings for fast, accurate, and alignment-free protein structure prediction. Structure 2022, 30, 1169–1177.e1164. [Google Scholar] [CrossRef]

- Zheng, W.; Zhang, C.; Li, Y.; Pearce, R.; Bell, E.W.; Zhang, Y. Folding non-homologous proteins by coupling deep-learning contact maps with I-TASSER assembly simulations. Cell Rep. Methods 2021, 1, 100014. [Google Scholar] [CrossRef]

- Hong, Y.; Lee, J.; Ko, J. A-Prot: Protein structure modeling using MSA transformer. BMC Bioinform. 2022, 23, 93. [Google Scholar] [CrossRef]

- Bian, Z.; Liu, H.; Wang, B.; Huang, H.; Li, Y.; Wang, C.; Cui, F.; You, Y. Colossal-AI: A unified deep learning system for large-scale parallel training. arXiv 2021, arXiv:2110.14883. [Google Scholar] [CrossRef]

- Khoury, G.A.; Smadbeck, J.; Kieslich, C.A.; Floudas, C.A. Protein folding and de novo protein design for biotechnological applications. Trends Biotechnol. 2014, 32, 99–109. [Google Scholar] [CrossRef] [PubMed]

- Anand, N.; Eguchi, R.; Mathews, I.I.; Perez, C.P.; Derry, A.; Altman, R.B.; Huang, P.-S. Protein sequence design with a learned potential. Nat. Commun. 2022, 13, 746. [Google Scholar] [CrossRef] [PubMed]

- Norn, C.; Wicky, B.I.M.; Juergens, D.; Liu, S.; Kim, D.; Tischer, D.; Koepnick, B.; Anishchenko, I.; Baker, D.; Ovchinnikov, S.; et al. Protein sequence design by conformational landscape optimization. Proc. Natl. Acad. Sci. USA 2021, 118, e2017228118. [Google Scholar] [CrossRef] [PubMed]

- Huang, P.-S.; Ban, Y.-E.A.; Richter, F.; Andre, I.; Vernon, R.; Schief, W.R.; Baker, D. RosettaRemodel: A generalized framework for flexible backbone protein design. PLoS ONE 2011, 6, e24109. [Google Scholar] [CrossRef] [PubMed]

- Bonet, J.; Wehrle, S.; Schriever, K.; Yang, C.; Billet, A.; Sesterhenn, F.; Scheck, A.; Sverrisson, F.; Veselkova, B.; Vollers, S.; et al. Rosetta FunFolDes—A general framework for the computational design of functional proteins. PLoS Comput. Biol. 2018, 14, e1006623. [Google Scholar] [CrossRef]

- Pan, X.; Thompson, M.C.; Zhang, Y.; Liu, L.; Fraser, J.S.; Kelly, M.J.S.; Kortemme, T. Expanding the space of protein geometries by computational design of de novo fold families. Science 2020, 369, 1132–1136. [Google Scholar] [CrossRef]

- Sherstinsky, A. Fundamentals of recurrent neural network (RNN) and long short-term memory (LSTM) network. Phys. D: Nonlinear Phenom. 2020, 404, 132306. [Google Scholar] [CrossRef]

- Meng, Y.; Zong, S.; Li, X.; Sun, X.; Zhang, T.; Wu, F.; Li, J. GNN-LM: Language modeling based on global contexts via GNN. arXiv 2021, arXiv:2110.08743. [Google Scholar]

- Wang, Y. A mathematical introduction to generative adversarial nets (GAN). arXiv 2020, arXiv:2009.00169. [Google Scholar] [CrossRef]

- Huang, P.-S.; Boyken, S.E.; Baker, D. The coming of age of de novo protein design. Nature 2016, 537, 320–327. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Zhang, J.Z.H. DenseCPD: Improving the accuracy of neural-network-based computational protein sequence design with DenseNet. J. Chem. Inf. Model. 2020, 60, 1245–1252. [Google Scholar] [CrossRef] [PubMed]

- Ferruz, N.; Schmidt, S.; Höcker, B. ProtGPT2 is a deep unsupervised language model for protein design. Nat. Commun. 2022, 13, 4348. [Google Scholar] [CrossRef]

- Anand, N.; Achim, T. Protein structure and sequence generation with equivariant denoising diffusion probabilistic models. arXiv 2022, arXiv:2205.15019. [Google Scholar]

- Hellinga, H.W.; Richards, F.M. Construction of new ligand binding sites in proteins of known structure: I. Computer-aided modeling of sites with pre-defined geometry. J. Mol. Biol. 1991, 222, 763–785. [Google Scholar] [CrossRef]

- Bolon, D.N.; Mayo, S.L. Enzyme-like proteins by computational design. Proc. Natl. Acad. Sci. USA 2001, 98, 14274–14279. [Google Scholar] [CrossRef] [Green Version]

- Zanghellini, A.; Jiang, L.; Wollacott, A.M.; Cheng, G.; Meiler, J.; Althoff, E.A.; Röthlisberger, D.; Baker, D. New algorithms and an in silico benchmark for computational enzyme design. Protein Sci. 2006, 15, 2785–2794. [Google Scholar] [CrossRef]

- Bi, J.; Jing, X.; Wu, L.; Zhou, X.; Gu, J.; Nie, Y.; Xu, Y. Computational design of noncanonical amino acid-based thioether staples at N/C-terminal domains of multi-modular pullulanase for thermostabilization in enzyme catalysis. Comput. Struct. Biotechnol. J. 2021, 19, 577–585. [Google Scholar] [CrossRef]

- Richter, F.; Blomberg, R.; Khare, S.D.; Kiss, G.; Kuzin, A.P.; Smith, A.J.T.; Gallaher, J.; Pianowski, Z.; Helgeson, R.C.; Grjasnow, A.; et al. Computational Design of Catalytic Dyads and Oxyanion Holes for Ester Hydrolysis. J. Am. Chem. Soc. 2012, 134, 16197–16206. [Google Scholar] [CrossRef]

- Bello, I.; Fedus, W.; Du, X.; Cubuk, E.D.; Srinivas, A.; Lin, T.Y.; Shlens, J.; Zoph, B. Revisiting ResNets: Improved training and scaling strategies. Adv. Neural Inf. Process. Syst. 2021, 34, 22614–22627. [Google Scholar] [CrossRef]

- Bennett, N.; Coventry, B.; Goreshnik, I.; Huang, B.; Allen, A.; Vafeados, D.; Peng, Y.P.; Dauparas, J.; Baek, M.; Stewart, L.; et al. Improving de novo protein binder design with deep learning. bioRxiv 2022, 15, 495993. [Google Scholar] [CrossRef]

- Iandola, F.; Moskewicz, M.; Karayev, S.; Girshick, R.; Keutzer, K. DenseNet: Implementing efficient ConvNet descriptor pyramids. arXiv 2014, arXiv:1404.1869. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, L.; Wang, W.; Zhu, M.; Wang, C.; Li, F.; Zhang, J.; Li, H.; Chen, Q.; Liu, H. Rotamer-free protein sequence design based on deep learning and self-consistency. Nat. Comput. Sci. 2022, 2, 451–462. [Google Scholar] [CrossRef]

- Sutskever, I.; Jozefowicz, R.; Gregor, K.; Rezende, D.; Vinyals, O. Towards principled unsupervised learning. arXiv 2015, arXiv:1511.06440. [Google Scholar] [CrossRef]

- Suzek, B.E.; Huang, H.; McGarvey, P.; Mazumder, R.; Wu, C.H. UniRef: Comprehensive and non-redundant UniProt reference clusters. Bioinformatics 2007, 23, 1282–1288. [Google Scholar] [CrossRef]

- Dhariwal, P.; Nichol, A. Diffusion models beat GANs on image synthesis. arXiv 2021. [Google Scholar] [CrossRef]

- Silva, D.-A.; Yu, S.; Ulge, U.Y.; Spangler, J.B.; Jude, K.M.; Labão-Almeida, C.; Ali, L.R.; Quijano-Rubio, A.; Ruterbusch, M.; Leung, I.; et al. De novo design of potent and selective mimics of IL-2 and IL-15. Nature 2019, 565, 186–191. [Google Scholar] [CrossRef]

- Cao, L.; Goreshnik, I.; Coventry, B.; Case, J.B.; Miller, L.; Kozodoy, L.; Chen, R.E.; Carter, L.; Walls, A.C.; Park, Y.-J.; et al. De novo design of picomolar SARS-CoV-2 miniprotein inhibitors. Science 2020, 370, 426–431. [Google Scholar] [CrossRef]

- Wang, B.; Su, Z.; Wu, Y. Computational assessment of protein–protein binding affinity by reversely engineering the energetics in protein complexes. Genom. Proteom. Bioinform. 2021, 19, 1012–1022. [Google Scholar] [CrossRef]

- Dou, J.; Vorobieva, A.A.; Sheffler, W.; Doyle, L.A.; Park, H.; Bick, M.J.; Mao, B.; Foight, G.W.; Lee, M.Y.; Gagnon, L.A.; et al. De novo design of a fluorescence-activating β-barrel. Nature 2018, 561, 485–491. [Google Scholar] [CrossRef] [PubMed]

- Krivacic, C.; Kundert, K.; Pan, X.; Pache, R.A.; Liu, L.; Conchúir, S.O.; Jeliazkov, J.R.; Gray, J.J.; Thompson, M.C.; Fraser, J.S.; et al. Accurate positioning of functional residues with robotics-inspired computational protein design. Proc. Natl. Acad. Sci. USA 2022, 119, e2115480119. [Google Scholar] [CrossRef] [PubMed]

| Enzyme (EC Number) | Catalytic Reaction | Commercial Source |

|---|---|---|

| Transglutaminase (EC 2.3.2.13) | Catalyzing the formation of heteropeptide bonds between the γ-amide group of the glutamine residue in the protein and the ε-amino group of Lys [36]. | Streptomyces mobaraense |

| Laccase (EC 1.10.3.2) | Catalyzing single-electron oxidation of phenols, aromatic amines, and other electron-rich substrates [45]. | Aspergillus oryzae, Mycyceliophora thermophila |

| Protein-glutaminase (EC 3.5.1.44) | Catalyzing the deamidation of Glu residues of proteins [46]. | Chryseobacterium proteolyticum |

| α-Amylase (EC 3.2.1.1) | Hydrolyzing α-1,4-glycosidic bonds inside starch [38]. | Bacillus licheniformis, Thermus Aquaticus |

| Lactase (EC 3.2.1.108) | Catalyzing the hydrolysis of β-D-galactoside and α-L-arabinoside [40]. | Bacillus subtilis, Bifidobacterium bifidum |

| α-Glucanase (EC 3.2.1.59); β-Glucanase (EC 3.2.1.73) | Hydrolyzing α/β-glucans [47]. | Bacillus subtilis, Bacillus amyloliquefaciens |

| Phosphatidylinositol-specific phospholipase C (EC 3.1.4.11) | Hydrolyzing the phosphodiester bond of phosphatidylinositol to diacylglycerol and water-soluble phosphoinositol [48]. | Pseudomonas fluorescens |

| Polygalacturonase (EC 3.2.1.15) | Catalyzing pectin molecule α-(1,4)-polygalacturonic acid cleavage [49]. | Trichoderma reesei, Aspergillus tubingensis |

| Pectinesterase (EC 3.1.1.11) | Hydrolyzing pectin to produce pectinic acid and methanol [43]. | Trichoderma reesei, Aspergillus tubingensis |

| endo-β-1,4-xylanase (EC 3.2.1.8) | Hydrolyzing xylan molecule β-1,4-glycosidic bonds [50]. | Trichoderma reesei, Thermopolyspora flexuosa |

| Lipases (EC 3.1.1.3) | Hydrolyzing triglycerides to glycerol and fatty acids [41]. | Trichoderma reesei, Fusarium oxysporum |

| 4-α-glucanotransferase (EC 2.4.1.25) | Catalyzing the breaking of α-1,4-glycosidic bonds and the transfer of α-glucan residues within or between molecules [51]. | Aeribacillus pallidus |

| Rennin (EC 3.4.4.3) | Hydrolyzing the peptide bond between Phe105-Met106 of κ-casein in milk [52]. | Kluyveromyces lactis |

| Cellulase (EC 3.2.1.4) | Hydrolyzing cellulose to produce glucose and oligomeric fiber [37]. | Trichoderma reesei |

| Glucose isomerase (EC 5.3.1.18) | Catalyzing isomerization of glucose to fructose [53]. | Streptomyces, Bacillus subtilis |

| α-glucosidase (EC 3.2.1.20) | Hydrolyzing the glycosidic bond of the non-reducing end of polysaccharides or converting the α-1,4-glycosidic bond of oligosaccharides into α-1,6-glycosidic bonds [53]. | Saccharomycetes, Aspergilusniger |

| Glucose oxidase (EC 1.1.3.4) | Oxidizing β-D-glucose to become gluconic acid and hydrogen peroxide [44]. | Aspergillus niger |

| Subtilisin (EC 3.4.21.62) | Hydrolyzing proteins into amino acids [54]. | Bacillus subtilis |

| Phytase (EC 3.1.3.8) | Catalyzing the removal of phosphate groups by inositol hexaphosphate [55]. | Natuphos |

| Enzyme and Source | Effect of Best Variant | Aims and Reference |

|---|---|---|

| Transglutaminase (Streptomyces mobaraenesis) | Tm and specific activity increased by 3.4 °C and 67.8%. | Processing tofu and fish balls at high temperatures. [27] |

| Glucoamylase (Talaromyces leycettanus) | Tm and specific activity increased by 9 °C and 305.4%. | Inducing the conversion of starch to glucose at high temperatures. [62] |

| Alpha-amylase (Rhizopus oryzae) | t1/2 (55 °C) increased by 2.55-fold. | Optimizing winemaking protocol. [63] |

| Cellulase (Penicillium canescens) | t1/2 (60 °C) increased by 3.4-fold. | Catalyzing the formation of gentiooligsaccharide at high temperatures. [64] |

| Serine protease (Pseudomonas aeruginosa) | Tm and specific activity increased by 5 °C and 1.4-fold. | Protease treatment at high temperatures enables fast processing and avoids bacterial contamination. [65] |

| Lipase (Yarrowia lipolytica) | t1/2 (50 °C) increased by 70%. | Optimizing grain and oil-processing protocol. [66] |

| Endoglucanase (Bipolaris sorokiniana) | Specific activity increased by 1.5-fold. | Enabling rapid food processing. [67] |

| Phytase (Escherichia coli) | Residual activity improved by 78.4% at 90 °C. | Used as animal feed supplement. [68] |

| Glucose isomerase (Thermoanaerobacter ethanolicus) | Specific activity increased by 2-fold. | High-fructose corn syrup one-step biosynthesis. [69] |

| β-glucanases (Bacillus terquilensis) | Improved acidic tolerance, and increased specific activity by 45%. | Serving food mashing process. [70] |

| Name | Description | Ref |

|---|---|---|

| AlphaFold-2 | Accurate, structures can be directly downloaded from a public dataset. Slow for protein modeling using source code. Database accessed from: https://alphafold.com/ (accessed on 5 February 2020) https://www.uniprot.org/ (accessed on 5 February 2020) | [22] |

| ESMFold | Accurate, structures can be directly downloaded from a public dataset. Database accessed from: https://esmatlas.com/about#download_dataset (accessed on 5 February 2020) | [106] |

| RoseTTAFold | Accurate, support for uploading up to 20 sequences for modeling. Relatively fast for protein modeling using source code. Webserver: https://robetta.bakerlab.org/ (accessed on 5 February 2020) | [77] |

| I-TASSER | Accurate, support for online uploading modeling tasks and using source code. Webserver: https://zhanggroup.org/I-TASSER/ (accessed on 5 February 2020) | [107] |

| trRosetta | Accurate, support for online uploading modeling tasks and using source code. Webserver: https://yanglab.nankai.edu.cn/trRosetta/help/ (accessed on 5 February 2020) | [103] |

| A-Prot | Only support for source code modeling. Source code: https://github.com/arontier/A_Prot_Paper (accessed on 5 February 2020) | [108] |

| Colossal-AI | Only support for source code modeling. Source code: https://github.com/hpcaitech/ColossalAI (accessed on 5 February 2020) | [109] |

| Name | Description | Ref |

|---|---|---|

| Match | Physics-based, structural-based, aims at designing de novo functional enzymes using fragment attempts. | [26] |

| Fixbb | Physics-based, structural-based, fit for short area design. | [96] |

| Remodel | Physics-based, structural-based, fit for short area design, can be used for protein reassembling. | [113] |

| FunFolDes | Physics-based, structural-based, blueprint-based whole protein de novo design. | [114] |

| LUCS | Physics-based, structural-based, fit for designing loop-helix-loop, loop-strand-loop. | [115] |

| TopoBuilder | Physics-based, structural-based, blueprint-based whole protein de novo design. | [34] |

| Protein Hallucination | AI-based, de novo design of whole protein structures with compatible sequences based on input sequence. | [32] |

| RFDesign | AI-based, “inpainting” module: designing short blocks based on given structure; “hallucination” module: designing short blocks based on a given structure, can be used for designing functional motifs, supporting receptor and donor structure. | [31] |

| ProteinMPNN | AI-based, fast designing compatible sequences using an input structure. | [33] |

| DenseCPD | AI-based, only supports uploaded tasks online, online server: http://protein.org.cn/densecpd.html | [120] |

| ProteinGAN | AI-based, GAN model for real-time generating sequences based on a set of input protein sequences (within the same protein family). | [35] |

| ProtGPT2 | AI-based, pre-trained model for generating sequences based on input sequence. | [121] |

| Diffusion model-based | AI-based, pre-trained model generating protein structures. | [122] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Xu, K.; Tan, Y.; Liu, S.; Zhou, J. Possibilities of Using De Novo Design for Generating Diverse Functional Food Enzymes. Int. J. Mol. Sci. 2023, 24, 3827. https://doi.org/10.3390/ijms24043827

Wang X, Xu K, Tan Y, Liu S, Zhou J. Possibilities of Using De Novo Design for Generating Diverse Functional Food Enzymes. International Journal of Molecular Sciences. 2023; 24(4):3827. https://doi.org/10.3390/ijms24043827

Chicago/Turabian StyleWang, Xinglong, Kangjie Xu, Yameng Tan, Song Liu, and Jingwen Zhou. 2023. "Possibilities of Using De Novo Design for Generating Diverse Functional Food Enzymes" International Journal of Molecular Sciences 24, no. 4: 3827. https://doi.org/10.3390/ijms24043827