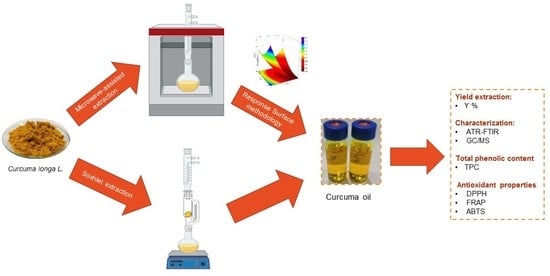

Microwave-Assisted Extraction of Curcuma longa L. Oil: Optimization, Chemical Structure and Composition, Antioxidant Activity and Comparison with Conventional Soxhlet Extraction

Abstract

:1. Introduction

2. Results and Discussion

2.1. MAE Based Experimental Design

2.1.1. Optimization of the Curcuma longa L. Oil Extraction

2.1.2. Effect of Independent Variables on Extraction Yield Response

2.1.3. Comparison of MAE and Soxhlet Extraction Yields

2.2. Characterization of the Extracted Curcuma longa L. Oil

2.2.1. Chemical Structure and Composition

2.2.2. Total Phenolic Content and Antioxidant Activity

3. Materials and Methods

3.1. Raw Materials and Chemicals

3.2. Extraction of Curcuma longa L. Oil

3.2.1. Microwave-Assisted Extraction (MAE)–Experimental Design

General Experiment Procedure

Experimental Design and Determination of the Optimal Extraction Conditions

3.2.2. Soxhlet Extraction

3.3. Characterization of the Curcuma longa L. Oil

3.3.1. Attenuated Total Reflection-Fourier Transform Infrared Radiation (ATR-FTIR)

3.3.2. GC/MS Analysis

3.3.3. Determination of the Total Phenolic Content (TPC)

3.3.4. Antioxidant Activity

DPPH Radical Scavenging Assay

FRAP Assay

2,2′-Azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) Assay

3.4. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Mishra, R.; Gupta, A.K.; Lal, R.K.; Jhang, T.; Banerjee, N. Genetic variability, analysis of genetic parameters, character associations and contribution for agronomical traits in turmeric (Curcuma longa L.). Ind. Crop. Prod. 2015, 76, 204–208. [Google Scholar] [CrossRef]

- Shirsath, S.; Sable, S.; Gaikwad, S.; Sonawane, S.; Saini, D.; Gogate, P. Intensification of extraction of curcumin from Curcuma amada using ultrasound assisted approach: Effect of different operating parameters. Ultrason. Sonochem. 2017, 38, 437–445. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Yang, Z.; Chen, F.; Su, P.; Chen, D.; Pan, W.; Fang, Y.; Dong, C.; Zheng, X.; Du, Z. Composition and bioactivity assessment of essential oils of Curcuma longa L. collected in China. Ind. Crop. Prod. 2017, 109, 60–73. [Google Scholar] [CrossRef]

- Gupta, S.C.; Sung, B.; Kim, J.H.; Prasad, S.; Li, S.; Aggarwal, B.B. Multitargeting by turmeric, the golden spice: From kitchen to clinic. Mol. Nutr. Food Res. 2012, 57, 1510–1528. [Google Scholar] [CrossRef] [PubMed]

- Chaaban, A.; Gomes, E.N.; Richardi, V.S.; Martins, C.E.N.; Brum, J.S.; Navarro-Silva, M.A.; Deschamps, C.; Molento, M.B. Essential oil from Curcuma longa leaves: Can an overlooked by-product from turmeric industry be effective for myiasis control? Ind. Crop. Prod. 2019, 132, 352–364. [Google Scholar] [CrossRef]

- Kiamahalleh, M.V.; Najafpour-Darzi, G.; Rahimnejad, M.; Moghadamnia, A.A.; Kiamahalleh, M.V. High performance curcumin subcritical water extraction from turmeric (Curcuma longa L.). J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2016, 1022, 191–198. [Google Scholar] [CrossRef] [PubMed]

- Park, S.-Y.; Kim, D.S.H.L. Discovery of Natural Products from Curcuma longa that Protect Cells from Beta-Amyloid Insult: A Drug Discovery Effort against Alzheimer’s Disease. J. Nat. Prod. 2002, 65, 1227–1231. [Google Scholar] [CrossRef] [PubMed]

- Hamaguchi, T.; Ono, K.; Yamada, M. REVIEW: Curcumin and Alzheimer’s Disease. CNS Neurosci. Ther. 2010, 16, 285–297. [Google Scholar] [CrossRef]

- Braga, M.E.M.; Leal, P.F.; Carvalho, J.E.; Meireles, M.A.A. Comparison of Yield, Composition, and Antioxidant Activity of Turmeric (Curcuma longa L.) Extracts Obtained Using Various Techniques. J. Agric. Food Chem. 2003, 51, 6604–6611. [Google Scholar] [CrossRef]

- Dao, T.T.; Nguyen, P.H.; Won, H.K.; Kim, E.H.; Park, J.; Won, B.Y.; Oh, W.K. Curcuminoids from Curcuma longa and their inhibitory activities on influenza A neuraminidases. Food Chem. 2012, 134, 21–28. [Google Scholar] [CrossRef]

- Das, N.; Dhiman, S.; Talukdar, P.; Rabha, B.; Goswami, D.; Veer, V. Synergistic mosquito-repellent activity of Curcuma longa, Pogostemon heyneanus and Zanthoxylum limonella essential oils. J. Infect. Public Health 2015, 8, 323–328. [Google Scholar] [CrossRef] [Green Version]

- Da Silva, M.R.M.; Ricci-Júnior, E. An approach to natural insect repellent formulations: From basic research to technological development. Acta Trop. 2020, 212, 105419. [Google Scholar] [CrossRef]

- Gopalan, B.; Goto, M.; Kodama, A.; Hirose, T. Supercritical carbon dioxide extraction of turmeric (Curcuma longa). J. Agric. Food Chem. 2000, 48, 2189–2192. [Google Scholar] [CrossRef] [PubMed]

- Sahne, F.; Mohammadi, M.; Najafpour, G.D.; Moghadamnia, A.A. Enzyme-assisted ionic liquid extraction of bioactive compound from turmeric (Curcuma longa L.): Isolation, purification and analysis of curcumin. Ind. Crop. Prod. 2017, 95, 686–694. [Google Scholar] [CrossRef]

- Chang, L.-H.; Jong, T.-T.; Huang, H.-S.; Nien, Y.-F.; Chang, C.-M.J. Supercritical carbon dioxide extraction of turmeric oil from Curcuma longa Linn and purification of turmerones. Sep. Purif. Technol. 2006, 47, 119–125. [Google Scholar] [CrossRef]

- Chassagnez-Méndez, A.L.; Machado, N.T.; Araujo, M.E.; Maia, J.G.; Meireles, M.A.A. Supercritical CO2 Extraction of Curcumins and Essential Oil from the Rhizomes of Turmeric (Curcuma longa L.). Ind. Eng. Chem. Res. 2000, 39, 4729–4733. [Google Scholar] [CrossRef]

- Wakte, P.S.; Sachin, B.; Patil, A.; Mohato, D.; Band, T.; Shinde, D. Optimization of microwave, ultra-sonic and supercritical carbon dioxide assisted extraction techniques for curcumin from Curcuma longa. Sep. Purif. Technol. 2011, 79, 50–55. [Google Scholar] [CrossRef]

- Martinez-Correa, H.A.; Paula, J.T.; Kayano, A.C.A.; Queiroga, C.L.; Magalhães, P.M.; Costa, F.T.; Cabral, F.A. Composition and antimalarial activity of extracts of Curcuma longa L. obtained by a combination of extraction processes using supercritical CO2, ethanol and water as solvents. J. Supercrit. Fluids 2017, 119, 122–129. [Google Scholar] [CrossRef]

- Hmar, B.Z.; Kalita, D.; Srivastava, B. Optimization of microwave power and curing time of turmeric rhizome (Curcuma longa L.) based on textural degradation. LWT 2017, 76, 48–56. [Google Scholar] [CrossRef]

- Priyanka; Khanam, S. Influence of operating parameters on supercritical fluid extraction of essential oil from turmeric root. J. Clean. Prod. 2018, 188, 816–824. [Google Scholar] [CrossRef]

- Yuan, Y.; Hong, S.; Lian, H.; Zhang, K.; Liimatainen, H. Comparison of acidic deep eutectic solvents in production of chitin nanocrystals. Carbohydr. Polym. 2020, 236, 116095. [Google Scholar] [CrossRef] [PubMed]

- Ye, W.; Wang, X.; Liu, Y.; Chen, J. Analysis and prediction of the performance of free-piston Stirling engine using response surface methodology and artificial neural network. Appl. Therm. Eng. 2021, 188, 116557. [Google Scholar] [CrossRef]

- Gullón, B.; Gullón, P.; Lú-Chau, T.A.; Moreira, M.T.; Lema, J.M.; Eibes, G. Optimization of solvent extraction of antioxidants from Eucalyptus globulus leaves by response surface methodology: Characterization and assessment of their bioactive properties. Ind. Crop. Prod. 2017, 108, 649–659. [Google Scholar] [CrossRef]

- Vijayan, U.K.; Varakumar, S.; Singhal, R.S. A comparative account of extraction of oleoresin from Curcuma aromatica Salisb by solvent and supercritical carbon dioxide: Characterization and bioactivities. LWT 2019, 116, 108564. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Sauraj; Kumar, B.; Deeba, F.; Kulshreshtha, A.; Negi, Y.S. Chitosan films incorporated with Apricot (Prunus armeniaca) kernel essential oil as active food packaging material. Food Hydrocoll. 2018, 85, 158–166. [Google Scholar] [CrossRef]

- Rohaeti, E.; Rafi, M.; Syafitri, U.D.; Heryanto, R. Fourier transform infrared spectroscopy combined with chemometrics for discrimination of Curcuma longa, Curcuma xanthorrhiza and Zingiber cassumunar. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2015, 137, 1244–1249. [Google Scholar] [CrossRef] [PubMed]

- Gunathilake, T.M.S.U.; Ching, Y.C.; Chuah, C.H.; Illias, H.A.; Ching, K.Y.; Singh, R.; Nai-Shang, L. Influence of a nonionic surfactant on curcumin delivery of nanocellulose reinforced chitosan hydrogel. Int. J. Biol. Macromol. 2018, 118, 1055–1064. [Google Scholar] [CrossRef]

- Chen, Z.; Quan, L.; Zhou, H.; Zhao, Y.; Chen, P.; Hu, L.; Yang, Z.; Hu, C.; Cao, N. Screening of active fractions from Curcuma longa Radix isolated by HPLC and GC-MS for promotion of blood circulation and relief of pain. J. Ethnopharmacol. 2019, 234, 68–75. [Google Scholar] [CrossRef]

- de Carvalho, F.A.L.; Munekata, P.E.; de Oliveira, A.L.; Pateiro, M.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Turmeric (Curcuma longa L.) extract on oxidative stability, physicochemical and sensory properties of fresh lamb sausage with fat replacement by tiger nut (Cyperus esculentus L.) oil. Food Res. Int. 2020, 136, 109487. [Google Scholar] [CrossRef]

- Patil, S.S.; Rathod, V.K. Synergistic Effect of Ultrasound and Three Phase Partitioning for the Extraction of Curcuminoids from Curcuma longa and its Bioactivity Profile. Process. Biochem. 2020, 93, 85–93. [Google Scholar] [CrossRef]

- Hayat, K.; Abbas, S.; Hussain, S.; Shahzad, S.A.; Tahir, M.U. Effect of microwave and conventional oven heating on phenolic constituents, fatty acids, minerals and antioxidant potential of fennel seed. Ind. Crop. Prod. 2019, 140, 111610. [Google Scholar] [CrossRef]

- Sanchez-Reinoso, Z.; Mora-Adames, W.I.; Fuenmayor, C.A.; Darghan-Contreras, A.E.; Gardana, C.; Gutiérrez, L.-F. Microwave-assisted extraction of phenolic compounds from Sacha inchi shell: Optimization, physicochemical properties and evaluation of their antioxidant activity. Chem. Eng. Process. Process. Intensif. 2020, 153, 107922. [Google Scholar] [CrossRef]

- Liang, H.; Wang, W.; Xu, J.; Zhang, Q.; Shen, Z.; Zeng, Z.; Li, Q. Optimization of ionic liquid-based microwave-assisted extraction technique for curcuminoids from Curcuma longa L. Food Bioprod. Process. 2017, 104, 57–65. [Google Scholar] [CrossRef]

- Pan, C.; Zhao, L.; Zhao, D. Microwave-assisted green extraction of antioxidant components from Osmanthus fragrans (Lour) flower using natural deep eutectic solvents. J. Appl. Res. Med. Aromat. Plants 2021, 20, 100285. [Google Scholar] [CrossRef]

- Fernández-Marín, R.; Labidi, J.; Andrés, M. Ángeles; Fernandes, S.C. Using α-chitin nanocrystals to improve the final properties of poly (vinyl alcohol) films with Origanum vulgare essential oil. Polym. Degrad. Stab. 2020, 179, 109227. [Google Scholar] [CrossRef]

- Gullón, B.; Eibes, G.; Moreira, M.T.; Dávila, I.; Labidi, J.; Gullón, P. Antioxidant and antimicrobial activities of extracts obtained from the refining of autohydrolysis liquors of vine shoots. Ind. Crop. Prod. 2017, 107, 105–113. [Google Scholar] [CrossRef]

| Experiments | Independent Variables | Normalized Variables | Extraction Yield | ||||

|---|---|---|---|---|---|---|---|

| t (min) | P (W) | R (g/mL) | X1 | X2 | X3 | YC-MAE % | |

| 1 | 20 | 200 | 1:8 | 0 | 0 | 0 | 9.50 |

| 2 | 30 | 150 | 1:8 | 1 | −1 | 0 | 8.59 |

| 3 | 30 | 200 | 1:5 | 1 | 0 | 1 | 4.00 |

| 4 | 10 | 150 | 1:8 | −1 | −1 | 0 | 5.58 |

| 5 | 30 | 250 | 1:8 | 1 | 1 | 0 | 6.92 |

| 6 | 10 | 200 | 1:5 | −1 | 0 | 1 | 7.06 |

| 7 | 10 | 200 | 1:20 | −1 | 0 | −1 | 7.41 |

| 8 | 20 | 250 | 1:20 | 0 | 1 | −1 | 4.48 |

| 9 | 20 | 200 | 1:8 | 0 | 0 | 0 | 9.35 |

| 10 | 10 | 250 | 1:8 | −1 | 1 | 0 | 6.12 |

| 11 | 20 | 150 | 1:20 | 0 | −1 | −1 | 10.84 |

| 12 | 20 | 250 | 1:5 | 0 | 1 | 1 | 3.03 |

| 13 | 30 | 200 | 1:20 | 1 | 0 | −1 | 9.27 |

| 14 | 20 | 200 | 1:8 | 0 | 0 | 0 | 9.47 |

| 15 | 20 | 150 | 1:5 | 0 | −1 | 1 | 6.77 |

| Coefficients | YC-MAE |

|---|---|

| b0 | 9.44 |

| b1 | 0.32 |

| b2 | −1.40 a |

| b3 | −1.39 a |

| b12 | −0.55 |

| b13 | −1.23 |

| b23 | 0.66 |

| b11 | −0.99 |

| b22 | −1.65 b |

| b33 | −1.51 |

| R2 | 0.82 |

| F-exp | 2.55 |

| F-critical | 0.16 |

| Significance level (%) | 84.24 |

| MAE | Soxhlet | ||||

|---|---|---|---|---|---|

| X1 (t, min) | X2 (P, W) | X3 (R, g/mL) | Y % (Predict Value) | YC-MAE % (Experimental Value) | YC-S % (Experimental Value) |

| 0.99 (29.99) | −0.79 (160.41) | −0.99 (1:20) | 10.92 | 10.32 ± 0.69 | 8.44 ± 0.17 |

| No. | Component | MAE | Soxhlet | ||

|---|---|---|---|---|---|

| A (%) | RT (min) | A (%) | RT (min) | ||

| 1 | α-curcumene | 0.55 | 18.8991 | 0.92 | 18.8993 |

| 2 | Zingiberene | 0.35 | 19.1652 | 0.54 | 19.1654 |

| 3 | β-Sesquiphellandrene | 0.65 | 19.7682 | 0.95 | 19.7684 |

| 4 | ar-Tumerol | 0.74 | 20.859 | 0.84 | 20.8592 |

| 5 | p-Cymene | 1.52 | 21.329 | 1.48 | 21.3293 |

| 6 | Zingiberenol | 0.26 | 21.7725 | 0.32 | 21.6929 |

| 7 | 3-Ethyl-N-methylaniline | 0.51 | 21.8434 | 0.44 | 21.8436 |

| 8 | ar-Turmerone | 33.78 | 22.3933 | 37.08 | 22.3935 |

| 9 | Tumerone | 20.12 | 22.4553 | 18.15 | 22.4555 |

| 10 | Bisacurol | 0.57 | 22.7657 | 0.25 | 22.7482 |

| 11 | β-Tumerone | 20.05 | 22.9786 | 19.22 | 22.9788 |

| 12 | (Z)-α-Atlatone | 0.52 | 23.1471 | 0.50 | 23.1473 |

| 13 | (6R, 7R)-bisabolone | 0.96 | 23.6437 | 1.00 | 23.6439 |

| 14 | (E)-α-Atlatone | 3.01 | 24.0516 | 2.38 | 24.0519 |

| 15 | (o)-Paradol | 0.66 | 24.6902 | 0.94 | 25.6861 |

| 16 | 2-Cyclohenen-1-one,6-[(1S)-1,5-dimethyl-3-oxo-4-hexen-1-yl]-3-methyl-(6S) | 0.68 | 25.8697 | 0.67 | 25.8699 |

| MAE | Soxhlet | |

|---|---|---|

| TPC (mg GAE/g) | 232.75 ± 0.31 a | 140.72 ± 0.42 b |

| DPPH (mg TE/g) | 64.71 ± 0.49a | 49.00 ± 0.33 b |

| FRAP (mg TE/g) | 255.66 ± 0.24 a | 73.37 ± 0.18 b |

| ABTS (mg TE/g) | 79.82 ± 0.03 b | 71.42 ± 0.04 a |

| Variables | Nomenclature | Units | Value or Range | |

|---|---|---|---|---|

| Independents | Reaction Time Microwave Power Ratio w/v (Curcuma longa L./EtOH) | t P R | min W g/mL | 10–30 150–250 1:20–1:5 |

| Dependent | Curcuma oil yield | Y | % | − |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-Marín, R.; Fernandes, S.C.M.; Andrés, M.A.; Labidi, J. Microwave-Assisted Extraction of Curcuma longa L. Oil: Optimization, Chemical Structure and Composition, Antioxidant Activity and Comparison with Conventional Soxhlet Extraction. Molecules 2021, 26, 1516. https://doi.org/10.3390/molecules26061516

Fernández-Marín R, Fernandes SCM, Andrés MA, Labidi J. Microwave-Assisted Extraction of Curcuma longa L. Oil: Optimization, Chemical Structure and Composition, Antioxidant Activity and Comparison with Conventional Soxhlet Extraction. Molecules. 2021; 26(6):1516. https://doi.org/10.3390/molecules26061516

Chicago/Turabian StyleFernández-Marín, Rut, Susana C. M. Fernandes, María A. Andrés, and Jalel Labidi. 2021. "Microwave-Assisted Extraction of Curcuma longa L. Oil: Optimization, Chemical Structure and Composition, Antioxidant Activity and Comparison with Conventional Soxhlet Extraction" Molecules 26, no. 6: 1516. https://doi.org/10.3390/molecules26061516